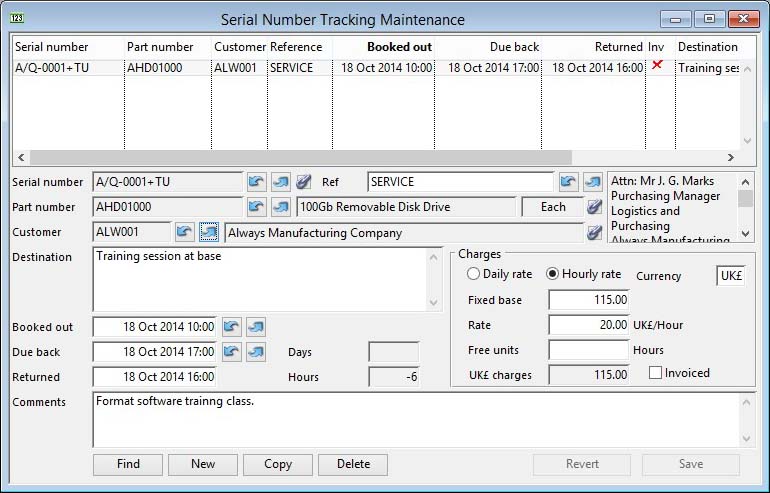

Serial Number Tracking Maintenance

Serial Number Tracking is a feature that enables a time-based record to be maintained of activities related to Product Serial Numbers. Access to Tracking records is available under the Serial Numbers Menu.

Serial Number Tracking can be used for a variety of purposes that involve time periods in which you charge fees.

![]() TIP: As part of your business you may rent machines or other items on a daily basis. Alternatively, you may provide service engineers that travel to the customer site for which you charge an hourly rate. Both of these cases can be handled with the Serial Number Tracking system.

TIP: As part of your business you may rent machines or other items on a daily basis. Alternatively, you may provide service engineers that travel to the customer site for which you charge an hourly rate. Both of these cases can be handled with the Serial Number Tracking system.

All maintenance functions are available as buttons on the maintenance window. In addition to these, you can use the navigation arrows to move from record to record and the ScratchPad to locate the first serial number record entered in the system for the selected part that has Tracking records. When you select a Serial Number, the system will build a list of any existing Tracking records and display this at the bottom of the window.

Serial number tracking records can be archived and deleted in the Data File Integrity Maintenance window.

|

Field |

Description |

|---|---|

|

Serial Tracking List |

A list of all tracking records for the Serial Number selected. Click to select. |

|

Serial Number |

Serial Number Tracking. Serial number tracked (inside relation to SNOSNO). {SNTFILE.SNTSNO char 18}

|

|

Reference |

Serial Number Tracking. Reference (similar to SOHCREF). {SNTFILE.SNTREF char 20} |

|

Part Number |

Product Serial Numbers. Part number. {SNOFILE.SNOPTNO char 18} |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Stock Unit of Measure |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Customer Code |

Serial Number Tracking. Customer code (inside relation to CUSCODE). {SNTFILE.SNTCUSC char 6} |

|

Customer Name |

Customers. Customer company name. {CUSFILE.CUSCNAM char 40} |

|

End User |

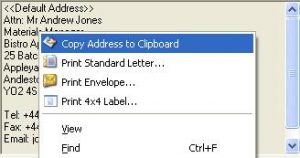

Shows the End User Address and Contact. Use the context menu to change if needed. This is an optional link to the customer’s address and contact data. It will be automatically set to the dispatch address/contact if the record was generated by a dispatch or return, but can be changed. The Address and Contact must belong to the assigned customer. Right-click on this field to obtain print functions for the currently selected address and contact:

Print Standard Letter opens the Standard Letter Selection window and Print 4×4 Label opens the 4 by 4 Label Position window. |

|

Destination |

Serial Number Tracking. Destination. {SNTFILE.SNTDEST char 300} |

|

Booked Out |

Serial Number Tracking. Outgoing date and time. {SNTFILE.SNTOUT date datetime idx} |

|

Due back |

Serial Number Tracking. Due back date and time. {SNTFILE.SNTDUED date datetime idx}

|

|

Returned |

Serial Number Tracking. Return date and time. {SNTFILE.SNTRET date datetime idx} |

|

Days |

The calculated number of days between the Booked Out date and the Returned date, rounded up (1 min over 24hrs = 2 days). |

|

Hours |

The calculated number of hours between the Booked Out date/time and the Returned date/time, rounded up (61 min = 2 hours). |

|

Comments |

Serial Number Tracking. Comments or remarks. {SNTFILE.SNTCOMM char 10000000} |

|

|

Charges |

|

Daily rate |

Serial Number Tracking. Units of charge (0=Days, 1=Hours). {SNTFILE.SNTUNIT integer shortint} The system can calculate charges on the basis of days or hours. Select your choice from the radio button options. In both cases, if the period of time includes a partial hour or day, a full unit is applied in the calculation. |

|

Hourly rate |

Serial Number Tracking. Units of charge (0=Days, 1=Hours). {SNTFILE.SNTUNIT integer shortint} |

|

Currency |

Serial Number Tracking. Currency symbol. {SNTFILE.SNTCUR char 3} |

|

Fixed Base Charge |

Serial Number Tracking. Base charge in currency. {SNTFILE.SNTBASE number 2dpShortnum} The component of charge that applies regardless of the duration recorded. The total charge is calculated as the Fixed Base + Rate x (the Hours (or Days) – the Free Units). |

|

Rate |

Serial Number Tracking. Charge in currency per unit. {SNTFILE.SNTCHAR number 2dpShortnum} The charge rate that applies to the duration recorded after deducting the Free units. You should take care to change the rate after any change to the Charged By units! |

|

Free Units |

Serial Number Tracking. Free units. {SNTFILE.SNTFREE number 2dpShortnum} This is the number of units (either Hours or Days) that are free to the customer. It is often the case that in rental arrangements there is a fixed fee for the first week followed by so much a day. For this example the Charges would be by Days, the Free Units would be 7.00 days and the Fixed Base Charge would be the week’s rental and the Rate would be the charge per day after the first week. |

|

Changes |

The calculated price based on the date/time period, the base, rate and free time. |

|

Invoiced |

Serial Number Tracking. Invoiced (Yes/No). {SNTFILE.SNTINV boolean} This is a simple indicator of whether you have invoiced the tracking record. There is no automatic invoicing system for Serial Number Tracking records, so this control has to be manually maintained. |

|

Button |

Action |

|---|---|

|

Find |

Enables you to enter a value in an indexed field. With the cursor in the field of interest, execute an OK. The record with the closest match to the entered value will be found and displayed. |

|

New |

This will create a new (normally blank) record in the file. You will then be able to enter details for the record. Then confirm with an OK, or abandon the New record with a Cancel. |

|

Copy |

This will create a Copy of the current record displayed on the window. You will then be able to change the details. Confirm with an OK, or abandon the new record with a Cancel. |

|

Delete |

Execute this button to permanently remove the currently selected record from the file. If you are permitted to delete the item, you will be asked for confirmation, otherwise an explanation will be given. |

|

Revert |

To revert any changes to the previously saved version. |

|

Save |

To save the changes you have made to the data file. |

|

Cancel |

Aborts the process currently in session. The keyboard equivalent is the Esc key for Windows computers and Command-.(full stop or period) for the Mac. |

|

OK |

The OK button updates the data you have entered, or confirms the selection and/or processes the function you have called. |

Tracking on Dispatch and Job Issue

You can, if you wish, set parts to be tracked automatically when they are dispatched or issued to a job and also marked with the Returned date/time when a Sales Return or job return of the item is recorded. This automatic processing is controlled by settings against the Part record in the Part maintenance window. You can also set these controls in Global Changes.

For automatic tracking to be effective both of the End Product Serial Numbering controls must be checked. Numbered on dispatch and job issue simply ensures that Serial Numbers are assigned when a dispatch or job issue takes place. Tracking on dispatch or job issue causes the system to create a new Serial Number Tracking record for each Serial Number that has been dispatched. If the two controls are checked, when a Return is recorded, the last tracking record for the serial number returned will be given the current date and time in the Returned field.

There is a system option available that will additionally create tracking records when a Job is completed in the Invoice Job window. Set the option optJobSnTracking to 1 for all serial numbers assigned to the job to have tracking records created if they are for parts with the Tracking on dispatch attribute set.

![]() WARNING: Automated Tracking uses the current terminal date and time when creating and updating records. To avoid subsequent editing of the tracking record you should ensure that the Dispatch and Return are recorded immediately they take place.

WARNING: Automated Tracking uses the current terminal date and time when creating and updating records. To avoid subsequent editing of the tracking record you should ensure that the Dispatch and Return are recorded immediately they take place.

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:49:00.00. Class wSntMaint last modified 10 Oct 2017 11:48:46.