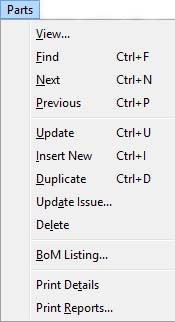

– Parts Menu

Provides commands for maintenance of parts master records. The Parts Master is the name given to the file that contains all the information that is unique to a specific Part in the system.

|

Line |

Function |

Keys |

|---|---|---|

|

View |

To view and maintain the current part in a new window. This function operates with the Part Maintenance window. |

|

|

Find |

To locate a specific part. Use the mouse or key board to enter some value in a field and confirm with an OK. The system will locate the closest match to the entered data and display the part record details. This function operates with the Part Maintenance window.

|

Ctrl+F |

|

Next |

The system will find the next part using the index of the value previously entered during the Find command. If it cannot find a part it will find the first based on the same criteria. In this way you can cycle through the part records. This function operates with the Part Maintenance window. |

Ctrl+N |

|

Previous |

Finds the previous part based on the index used by a previous Find. If you are on the first record, the system will find the last. In this way you can cycle through the parts in descending order. This function operates with the Part Maintenance window. |

Ctrl+P |

|

Update |

With a part displayed, you can edit its details and use this command to save the changes to file. This function operates with the Part Maintenance window. |

Ctrl+U |

|

Insert New |

To create a new part, providing it with a unique identifying part number. This function operates with the Part Maintenance window.

|

Ctrl+I |

|

Duplicate |

To copy all details of the currently selected part to a new part record. It must be provided with its own unique identifying part number. This function operates with the Part Maintenance window. When duplicating a part which has a BoM Structure, Process Route, Quality Assurance Regime and/or Serial Number Structure, you will be asked if these too are to be duplicated for the new part. You must have appropriate privileges for each data set and the Serial Number structure will not be offered if the BoM is not duplicated.

|

Ctrl+D |

|

Update Issue |

To update the Engineering Issue on all references to the currently selected part. Changes will be made to BoM components, Job items, Serial Numbered items, PO line items and WOs. This function operates with the Part Maintenance window. It additionally opens the Update Part Issue and References window. |

|

|

Delete |

To delete a part. You will be prevented from deleting parts that are referenced elsewhere in the system. Use the special stock changes function in the manager menu to delete parts and their history. This function operates with the Part Maintenance window.

|

|

|

BoM Listing |

To provide a simple assembly listing and single level ‘where used’ listing for the currently selected and displayed part. This function opens the Bill of Materials and Where-Used Listings window which works interactively with the parts Scratchpad. |

|

|

Print Details |

To print the selected part details in full. This function operates with the Part Maintenance window. |

|

|

Print Reports |

Provides for a range of reports containing information in the parts master. This function opens the Parts Report Selection window which uses the Part Selection subwindow. |

|

| See also: – |

Compiled in Program Version 5.10. Help data last modified 23 Feb 2016 09:46:00.00. Class mPartsCmd last modified 16 Apr 2012 05:29:49.