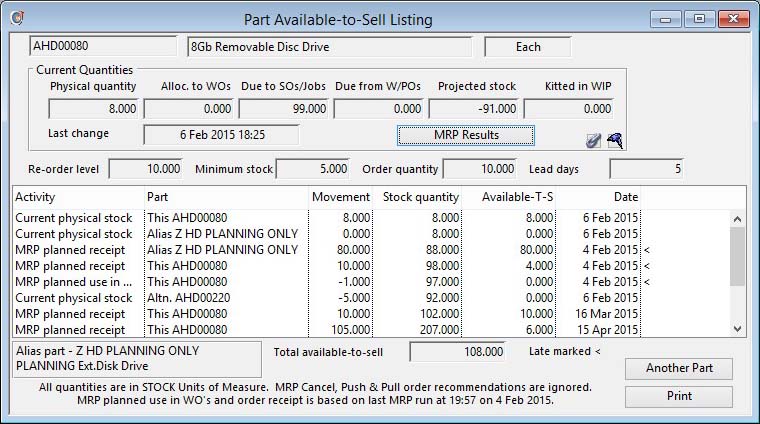

Part Available-to-Sell Listing

This window is used by the Process — Sales Orders — Review Part Available To Sell menu function.

This function provides a forecast listing of a part’s inventory projected activity. From this the user can establish what is available to commit, or Available-To-Sell, to a customer and when dispatch will be possible. You are presented the Part Selection window in which you must select the part of interest.

If the part selected has a Planning Alias part you have the option of including the Alias part into the analysis. If you include the Alias the supply of the Alias is included as well as any net demand from parts that also have the same Alias.

Information is gained from current purchase, sales and work orders, MRP results and the current physical stock position.

MRP planned use in Work Orders (dependant demand) and MRP planned order delivery are accurate only at the time of the MRP run that is shown under the list. In addition, Cancel, Push and Pull order MRP recommendations are ignored.

The Available-T-S column shows the quantity that will be additionally available, over and above zero stock for the part, after the movement has taken place.

With a simple, non-Alias, analysis the listing shows all predictable supply and demand for the part:

Supply:

- Current physical quantity in stock

- Purchase Order receipts due (not marked as Ignore for MRP)

- Work Order completion due (not marked as Ignore for MRP)

- MRP predicted supply (recommended supply from future production)

Demand:

- Shortages logged during WO kit issues, PO Outwork kit issues or SO exploded kit dispatches.

- Sales Order items due to dispatch (not Quotations)

- Sales Order exploded kit components due for dispatch

- Purchase Order Outwork Assembly kit components due to issue

- Un-issued Job items

- MRP predicted dependant demand (predicted consumption in future production)

All of these supply and demand quantities are built into a list and then sorted by the date predicted for the movement, with the current physical quantity on the first line. From this, the Stock quantity is then calculated. Finally, the Available-to-Sell quantities are then computed by working backwards up the list identifying when surplus quantities become available to commit as new orders to customers. In effect, the Available-to-Sell tells you the quantity that can be committed to new customer orders for delivery on the dates the quantity is shown against. Once you book a new order, any further analysis will show a reduced Available-to-Sell. If the Available-to-Sell is negative, it implies that commitments are running ahead of projected supply.

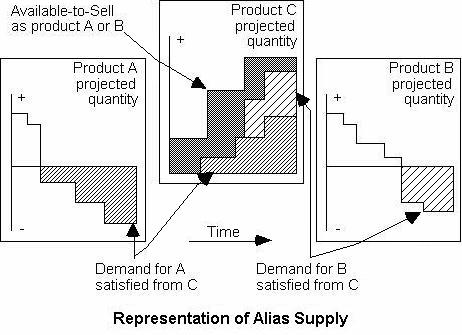

If the part has an Alias and you choose to include the Alias in the analysis, you can, in effect, gain a view of the Available-to-Sell with respect to the selected part’s projected condition within the framework of a family of products.

Say both products A and B are variants of the same basic product C. Parts A and B are both given part C as an Alias. “Production Planning and Forecasting” is done solely for the basic product C, which itself compensates for this Alias relationship. MRP then produces a manufacturing schedule for C. If you do an Available-to-Sell analysis for product A, its supply and demand is analysed. Any projected free physical and future supply of Alias C is also considered available, taking into account any net demand that will also be drawn from Alias C by the other product B.

![]() NOTE: Using the Alias concept with sensible Sales Forecasting in the “Production Planning” section and regular MRP runs, can make a very powerful combination. However, if the choice of Alias to Product is not appropriate it can mislead users into thinking that sales commitments can be made when it is not realistic.

NOTE: Using the Alias concept with sensible Sales Forecasting in the “Production Planning” section and regular MRP runs, can make a very powerful combination. However, if the choice of Alias to Product is not appropriate it can mislead users into thinking that sales commitments can be made when it is not realistic.

![]() TIP: You can also make use of the Alias as simply a direct substitute for the product of interest. In this case, if there is no supply of the product, the Alias can be sold to the customer. See also the Sales Order Line Item Maintenance paragraphs with respect to warnings when entering Order Quantity.

TIP: You can also make use of the Alias as simply a direct substitute for the product of interest. In this case, if there is no supply of the product, the Alias can be sold to the customer. See also the Sales Order Line Item Maintenance paragraphs with respect to warnings when entering Order Quantity.

![]() TIP: For those that buy to sell, you can use the list context menu to control which PO Line Item date is used when generating the analysis. Right-click on the list and select from the following:

TIP: For those that buy to sell, you can use the list context menu to control which PO Line Item date is used when generating the analysis. Right-click on the list and select from the following:

- Use PO Due Date

- Use PO Originally Promised

- Use PO Latest Expected

Your choice will be retained in your User Settings for the next time you use the window.

|

Field |

Description |

|---|---|

|

Part Number |

Parts Master. Part number unique identifier. {PTMFILE.PTMPTNO char 18} |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Stock Unit of Measure |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Current Quantities |

For details see the Parts Current Quantity subwindow. |

|

Re-Order Level |

Parts Master. Re-Order level. {PTMFILE.PTMROLE number 3dp} |

|

Minimum Stock |

Parts Master. Minimum stock level. {PTMFILE.PTMMINS number 3dp} |

|

Re-Order Quantity |

Parts Master. Re-order quantity. {PTMFILE.PTMREQT number 3dp} |

|

Lead Time |

Parts Master. Lead time in active (buy or make) days. {PTMFILE.PTMLEAD number 0dpShortnum} |

|

Available-to-Sell List |

Lists all committed and forecast movements for the selected part. The available-to-sell column represents the quantity and date on which you can commit to further sales deliveries. |

|

Alias Message |

Parts Master. Planning Alias part number. {PTMFILE.PTMALIA char 18} |

|

Total |

The total available-to-sell over the entire forecast range and is equivalent to the planned available inventory surplus to commitments. |

|

Button |

Action |

|---|---|

|

Another Part |

To choose an alternate part for analysis. It opens the Part Selection window. |

|

|

To print a report of the listing shown. Right-click to change the report destination. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 7 Jul 2017 12:57:00.00. Class wSalesPlan last modified 10 Oct 2017 11:48:42.