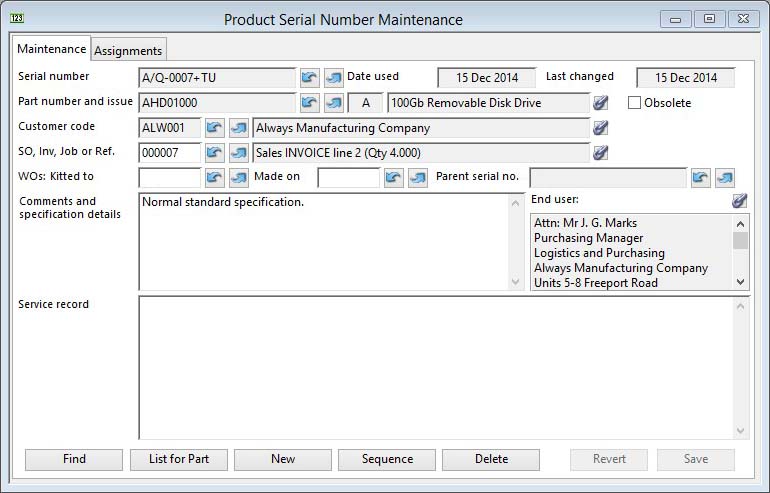

Product Serial Number Maintenance

End products and other parts may require separate Serial Number records. This is provided for in the system from the Serial Numbers Menu.

All maintenance functions are available as buttons on this maintenance window. In addition to these, you can use the navigation arrows to move from record to record and the ScratchPad to locate the first serial number record entered in the system for the selected part. You can also interactively click on the List for Part button and select a serial number from the Serial Number Listing window.

You can define a serial number hierarchy that can follow your bill of material structure. For instance, a car contains an engine that contains a fuel management controller. Each is independently serial numbered but when assembled in the car have distinct dependency within a defined hierarchy. This structure can be set up using the Set Up Serial Number Structure function in the BoM Menu. See the Serial Number Structure window for more details.

The window has 2 tab panes.

Maintenance

To select and maintain a serial number record.

|

Field |

Description |

|---|---|

|

Serial Number |

Product Serial Numbers. Serial number. {SNOFILE.SNOSNO char 18} Up to 18 characters of any type including punctuation. It must be unique and can be constructed in the Sequence function.

|

|

Date used |

Product Serial Numbers. Date used (either assigned in a structure, used in a WO or dispatched from a SO). {SNOFILE.SNODATE date date1980} This date is automatically entered if the serial number is assigned on a Dispatch or WO or assigned to a structure, otherwise it can be manually entered. |

|

Last Modified |

Product Serial Numbers. Last editing activity. {SNOFILE.SNOLAST date date1980} |

|

Part Number |

Product Serial Numbers. Part number. {SNOFILE.SNOPTNO char 18} It is mandatory that a pre-defined part is assigned to the serial number. It need not be flagged with a Product Serial Numbering Option in the part details.

|

|

Part Issue |

Product Serial Numbers. Part issue reference. {SNOFILE.SNOISSU char 4} This field defaults to the current Issue Reference for a Part. You can change it to reflect an alternative to the current issue. It is subject to update in the Update Issue function in the Parts Menu. |

|

Part Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Obsolete |

Product Serial Numbers. Do not use this serial number (obsolete, scrapped or otherwise). {SNOFILE.SNOBAR boolean} |

|

Customer Code |

Product Serial Numbers. Customer code. {SNOFILE.SNOCUSC char 6} Optionally you may link a serial number record to a particular customer, which must be pre-defined in Customers. If you make an assignment to a suitable document the customer code will be applied automatically. |

|

Customer Name |

Customers. Customer company name. {CUSFILE.CUSCNAM char 40} |

|

SO, Invoice, Job or Reference |

Product Serial Numbers. Invoice number, SO number or Dispatch Note number. {SNOFILE.SNOIVNO char 6} Product Serial Numbers can be assigned to both Sales Order line items, Jobs and Invoice line items and Work Orders. If a Serial Number is assigned to a Sales Order or Job it will appear on the Sales Order or Job picking list and will be automatically assigned to the serial number list during the dispatch or issue confirmation process. If it is assigned to an Invoice the Serial Number will be printed on the Invoice.

|

|

Document Details |

The document, if any, that the serial number record is assigned to. It may be either a Sales Order or an Invoice. |

|

Work Order – Kitted to |

Product Serial Numbers. Work Order number when the serial numbered part is a component issued or allocated to a WO. {SNOFILE.SNOWONO char 6} |

|

Work Order – Made on |

Product Serial Numbers. Work Order number when the serial numbered part is the assembly made on the WO. {SNOFILE.SNOWOMK char 6} |

|

Parent Serial Number |

Product Serial Numbers. Parent serial number when allocated in a chained assembly structure. {SNOFILE.SNOPSNO char 18} |

|

End User |

Shows the End User Address and Contact. Use the context menu to change if needed. This is an optional link to the customer’s address and contact data. It will be automatically set to the dispatch address of an invoice-linked record, but can be changed. The Address and Contact must belong to the assigned customer. Right-click on this field to obtain print functions for the currently selected address and contact:

Print Standard Letter opens the Standard Letter Selection window and Print 4×4 Label opens the 4 by 4 Label Position window. |

|

Comments and Specification Details |

Product Serial Numbers. Notes and comments. {SNOFILE.SNOCOMM char 32000} |

|

Service Record |

Product Serial Numbers. Service notes and history. {SNOFILE.SNOSERV char 32000} |

|

Button |

Action |

|---|---|

|

Find |

Enables you to enter a value in an indexed field. With the cursor in the field of interest, execute an OK. The record with the closest match to the entered value will be found and displayed. |

|

List for Part |

To show an interactive list of all serial numbers for the selected part. It opens the Serial Number Listing window. |

|

New |

This will create a new (normally blank) record in the file. You will then be able to enter details for the record. Then confirm with an OK, or abandon the New record with a Cancel. |

|

Sequence |

Will allow you to create a sequence of serial numbers for a particular part in one go, optionally based on the currently selected record but with no service history. The button opens the Serial Number Sequence Setup window. |

|

Delete |

Execute this button to permanently remove the currently selected record from the file. If you are permitted to delete the item, you will be asked for confirmation, otherwise an explanation will be given. |

|

Revert |

To revert any changes to the previously saved version. |

|

Save |

To save the changes you have made to the data file. |

|

Cancel |

Aborts the process currently in session. The keyboard equivalent is the Esc key for Windows computers and Command-.(full stop or period) for the Mac. |

|

OK |

The OK button updates the data you have entered, or confirms the selection and/or processes the function you have called. |

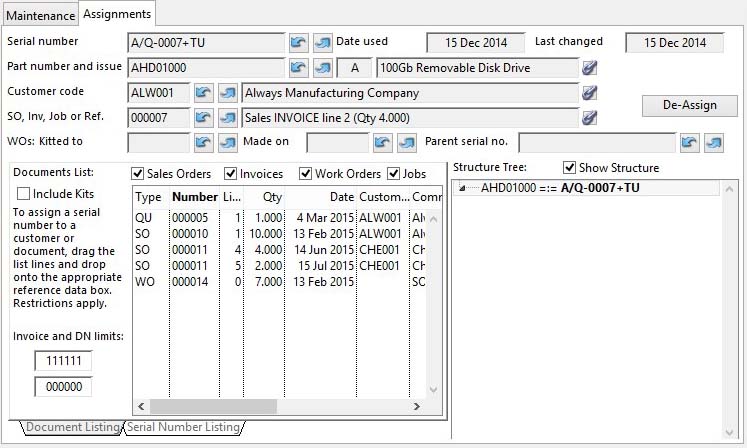

Assignments

This pane is used to assign a serial number record to a Sales Order, Job, Invoice, Work Order or a parent serial number.

A serial number record can be assigned to a Sales Order, Job, Dispatch Note or Invoice Line. They may additionally be associated with a Work Order. They can also be assigned to a parent serial number inside a serial number hierarchical structure.

Typically, these assignments are made during processing activities such as Dispatch. However, this pane enables you to manually make these assignments.

|

Button |

Action |

|---|---|

|

De-assign |

Click to de-assign from the customer and document. You will need to save the record after operating this button. To de-assign work order references, edit the fields blank. |

|

Field |

Description |

|---|---|

|

Show Structure |

Check to view a structure list and assignments in the structure. |

|

Structure Tree List |

The defined structure for the part and any assignments applicable. Use the Delete key to de-assign serial numbers in the structure. |

Assignment Listing Tab Pane

Select Document Listing to assign documents to the serial number, or Serial Number Listing to assign serial numbers to the Structure Tree.

Document Listing

This pane is used to list documents associated with the selected serial numbered part. You can drag a listed document and drop it onto the appropriate reference field to make an assignment.

|

Field |

Description |

|---|---|

|

Sales Orders |

Check to include sales order items in the assignment list. |

|

Invoices |

Check to include invoice items in the assignment list. |

|

Work Orders |

Check to include work orders in the assignment list. |

|

Jobs |

Check to include estimates and jobs in the assignment list. |

|

Include Kits |

Check to include parent kits where appropriate in the assignment list. |

|

From and To Invoice and DN |

Enter a restrictive range of invoice and dispatch note numbers for the listing. |

|

Document List |

A list of available options for assignment of the serial number. To assign, drag a line to the appropriate entry. |

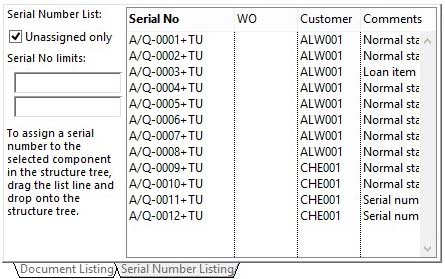

Serial Number Listing

This pane is used to list un-assigned serial numbers for the part selected in the structure tree. You can then drag a line and drop it onto an unassigned part in the structure tree to assign it within the structure.

|

Field |

Description |

|---|---|

|

Unassigned only |

This will restrict the list to only those serial numbers that are not yet assigned to a parent. Otherwise all serial number for the part are listed within the to and from range. |

|

From and To Serial Numbers |

Enter a restrictive range of serial numbers for the listing. |

|

Serial Number List |

A list of serial numbers for the selected component part in the structure tree. Drag lines from this list to make assignments on the structure tree. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 23 Feb 2016 10:30:00.00. Class wSnoEdit last modified 28 Apr 2018 08:09:53.