Stock Availability Analysis for Demand

This window function enables you to construct a list of demand parts with appropriate quantities and due dates and then analyse the stock consequences, as though you were to load the demand in the form of Sales Orders or Jobs.

The analysis identifies any projected stock shortages and suggests dates on which such shortages can be satisfied from additional production or purchases.

It analyses the future stock position using Part Process Analysis for all parts that are not N-type and calculates the shortage quantity, if any, on the date it is due and shows the next available date that the shortage can be satisfied.

An icon shows in the Action column for a part line where the shortage is satisfied on the Available date by way of an additional purchase or production order. Where no icon shows, shortages will be satisfied by current supply orders.

If there is going to be a shortage in the future, due to the new demand even if that new demand can be met on the due date, a future shortage date will be shown. If there are no results to the Part Process Analysis, because the projected stock is the same as the current physical stock, any net shortage is assumed to be due in the lead time from today (i.e. It expects you to place an order today). If a part line has a zero shortage quantity and a future shortage date, it means that while the new demand from this order or job can be satisfied from projected stock, the use of that stock for this new demand will leave shortages on other demands for the part.

If the part has a shortage quantity, is not a B-type part and there is a Bill of Material for it, it’s components will be listed to be due on the lead days back from the parent’s due date. These components are added to the list in a quantity appropriate to the parent’s net shortage. These are in turn analysed in the same way (i.e. The analysis operates on net shortages multi-level.). For correct analysis of kits (P-type assemblies), the phantom parent should have zero lead time. Parts with no shortage but with a future shortage date are not analysed multi-level. (i.e. Future shortages consequential to the new demand from this order or job are not analysed for lower-level future shortages of components). As a consequence of any component shortages, any parent assemblies will have their Available Date pushed forward accordingly up the BoM tree. Where several common parts with different dates, or different parts with common sub-assemblies, constitute demand, multiple entries of shortage components will be listed with an Order Line and Parent Part columns in the list indicating where they belong. Consumption of available stock is assumed to be in order of due date and then order line number.

![]() WARNING: Using Part Process Analysis in this way does assume that when demand is confirmed in the form of Sales Orders or Jobs, the lower-level dependant demand is implemented through MRP by raising appropriate Works and Purchase Orders. WO’s do not need to be kitted but they do need to be created (not backflushed) so that their process movements are seen in Part Process Analysis. This is because if this is not done, lower-level dependant demand from demand already on the system is not seen in the analysis and therefore under-estimated. This planning tool is only truly valid when used in a well disciplined MRP-managed environment.

WARNING: Using Part Process Analysis in this way does assume that when demand is confirmed in the form of Sales Orders or Jobs, the lower-level dependant demand is implemented through MRP by raising appropriate Works and Purchase Orders. WO’s do not need to be kitted but they do need to be created (not backflushed) so that their process movements are seen in Part Process Analysis. This is because if this is not done, lower-level dependant demand from demand already on the system is not seen in the analysis and therefore under-estimated. This planning tool is only truly valid when used in a well disciplined MRP-managed environment.

There are a few things to know:

- You can right-click and print the list.

- The button loads the ScratchPad with parts in selected lines.

- Double-click on a list line to drill down to Process Analysis.

- Change of list sort is remembered while a session is in progress (i.e. Back/Next) but it will default to the Available Date column when the list is first displayed within a session.

The window has 2 tab panes.

Future Demand

Shortage Analysis

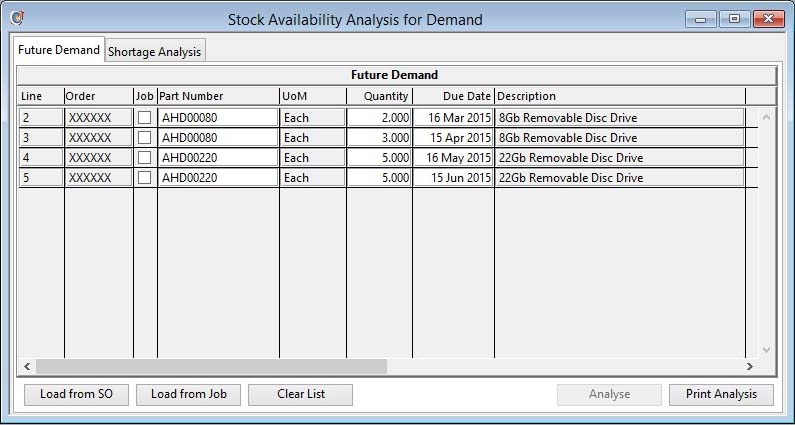

Future Demand

Load the future demand that you want to analyse in this tab pane.

Tab through the last line to add a further line.

You can populate the list by dragging part lines from the Parts ScratchPad or BoM Listing window.

![]() TIP: The load list can be automatically populated from a Sales Order, Quotation, Job or Estimate (even when un-saved) using the Sales Order or Jobs context menu (right-click) command. When operated on a saved SO or Job it analyses the existing order or job.

TIP: The load list can be automatically populated from a Sales Order, Quotation, Job or Estimate (even when un-saved) using the Sales Order or Jobs context menu (right-click) command. When operated on a saved SO or Job it analyses the existing order or job.

|

Field |

Description |

|---|---|

|

List of demand |

List of parts with quantity and due date that will be used in the analysis. To ignore an entry already made set the part blank, the quantity to zero or blank the due date. |

|

Line number |

The actual or supposed order line number. |

|

Order |

The document number, or XXXXXX for new unconfirmed demand. |

|

Job |

Check this option if the demand is deriving from a Job rather than a Sales Order. It controls the subsequent list icons and is needed to tie up existing acknowledged demand. |

|

Part |

Parts Master. Part number unique identifier. {PTMFILE.PTMPTNO char 18 Idx} |

|

Stock UoM |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Quantity |

Enter the quantity in stock units that are required on the due date. |

|

Due Date |

Enter here the date that the demand will be due. |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Button |

Action |

|---|---|

|

Load from SO |

To load the demand list from an existing Sales Order. |

|

Load from Job |

To load the demand list from an existing Job. |

|

Clear List |

To clear the list for a new demand analysis. |

|

Analyse |

Click to analyse the demand entered. This will switch you to the Analyse tab pane automatically. |

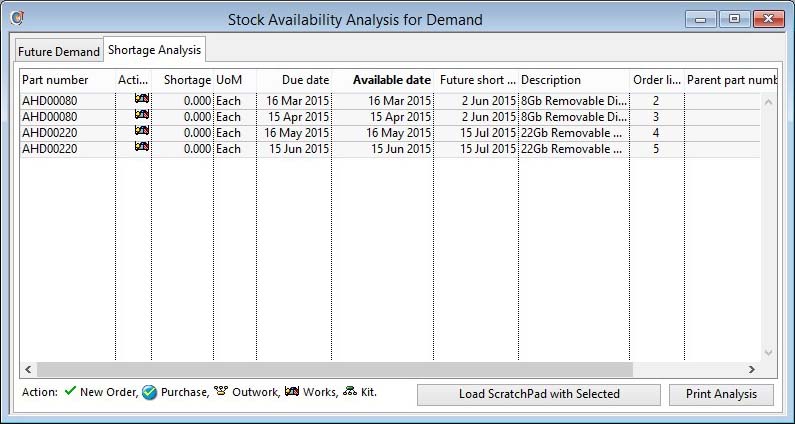

Shortage Analysis

To view the shortage analysis of your future demand.

List of components that are predicted to be short from stock on the date needed. Double-click to view Part Process Analysis.

|

Button |

Action |

|---|---|

|

Load ScratchPad with Selected |

Click to load the Parts ScratchPad with the selected parts in the list. |

|

Print Analysis |

Will cause a report to be printed of the subject matter. Right-click to change the report destination. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:49:00.00. Class wSoDemandAnalyse last modified 23 Sep 2017 10:51:08.