System Preferences

This window open from the File — System Manager — System Preferences menu function.

These preferences are business-wide controls held centrally with the Company Details. They contain controls that will apply to all users of the system, as opposed to Options and Settings that may apply only to the operation of a particular terminal, user or group of users.

Most controls are on/off switches – a checked box switches that control ON.

Certain data items can only be changed and saved when you are the only user on the system. If you change a value the Save Changes and Revert to Saved buttons become enabled. A message will also appear at the bottom right to indicate either “Saving your changes can be made with other users on the system” or “Saving your changes requires Single-User operation”. In the later case you can only save changes if you are the only user on the system. If you are not, you will receive a message with the Multi-user Warning Message window.

|

Field |

Description |

|---|---|

|

Last Modified Data and Time |

Company and System Settings. Last modified date and time. {MCDFILE.MCDMOD date datetime 8} |

|

Button |

Action |

|---|---|

|

|

To print a report of all company details. Right-click for report destination. |

|

Revert to Saved |

To edit the company details. No other users can be operating on the data file. |

|

Save Changes |

To edit the company details. No other users can be operating on the data file. |

The window has 7 tab panes.

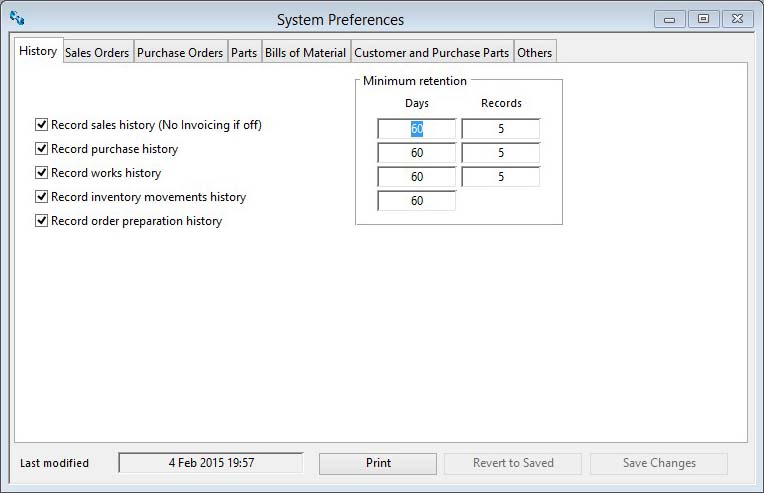

History

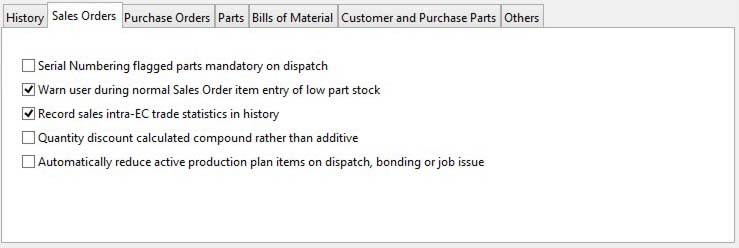

Sales Orders

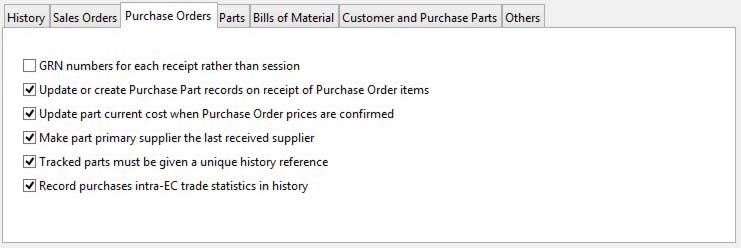

Purchase Orders

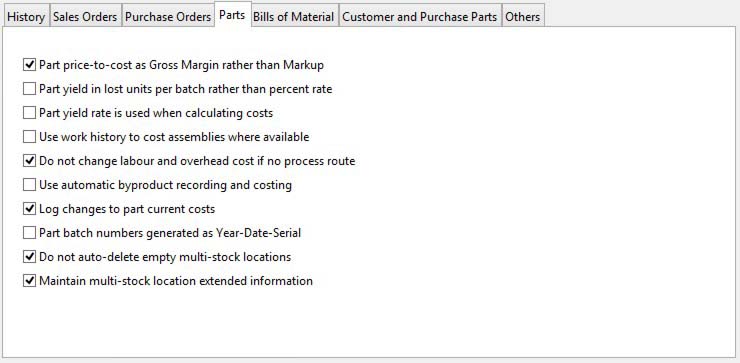

Parts

Bills of Material

Customer and Purchase Parts

Others

History

Checkboxes control whether history is recorded automatically by the system when transactions are processed. In addition, you can set the extent of history retention when processing the Period Routines clear-out of old history. Retention is both by a number of days and the number of records retained for each part regardless of age. This means that for 60 days and 5 records, a part history record will only be deleted if it is more than 60 days old AND five later records remain on file for the part. This approach ensures that both fast and slow moving items retain appropriate and sufficient history.

|

Field |

Description |

|---|---|

|

Record sales history (No Invoicing if off) |

Company and System Settings. Record sales history flag. {MCDFILE.MCDSHFL boolean} Sales history is maintained for each dispatch and return of a Sales Order line item and is used to create Sales Invoices after dispatch. If this is turned off the Sales Invoicing capabilities are unavailable. If you are licensed with Ledgers, you will not be able to switch sales history off. History is recorded for both part and non-part P.O. line items. |

|

Record purchase history |

Company and System Settings. Record purchase history flag. {MCDFILE.MCDPHFL boolean} Purchase history is maintained for each receipt of a Purchase Order line item. History is recorded for both part and non-part P.O. line items. Turning off purchase history will not effect the updating of Purchase Parts records. |

|

Record works history |

Company and System Settings. Record works order history. {MCDFILE.MCDWHFL boolean} Work history is maintained for each completed batch process route operation of a Work Order. If an assembly has 6 process route operations and a Work Order is completed in 2 batches, 12 history records will be created for the WO. |

|

Record inventory movements history |

Company and System Settings. Record inventory history flag. {MCDFILE.MCDIHFL boolean} Inventory (stock) movement history is a part-specific history of every activity relating to the part and includes all stores movements. Inventory History is, in effect, an audit trail of part movements and only has chronological relevance and therefore has no minimum retention records. |

|

Record order preparation history |

Company and System Settings. Record S/P/W Order preparation audit data in inventory movements. {MCDFILE.MCDORFL boolean} Order Preparation History records are additional inventory records created during order processing. They show creation of order items and changes to them. Only valid part number items are recorded in this way, not non-part Purchase and Sales Order line items. Inventory movement history retention days applies to order preparation history. |

|

Sales Retention Days |

Company and System Settings. Sales history minimum days data retention. {MCDFILE.MCDSHDY number 0dpShortnum} |

|

Sales Retention Minimum Records |

Company and System Settings. Sales history minimum record retention. {MCDFILE.MCDSHRR integer shortint} |

|

Purchases Retention Days |

Company and System Settings. Purchase history minimum days data retention. {MCDFILE.MCDPHDY number 0dpShortnum} |

|

Purchases Retention Minimum Records |

Company and System Settings. Purchase history minimum record retention. {MCDFILE.MCDPHRR integer shortint} |

|

Works Retention Days |

Company and System Settings. Works order history minimum days data retention. {MCDFILE.MCDWHDY number 0dpShortnum} |

|

Works Retention Minimum Records |

Company and System Settings. Works history minimum record retention. {MCDFILE.MCDWHRR integer shortint} |

|

Inventory Retention Days |

Company and System Settings. Inventory history minimum days data retention. {MCDFILE.MCDIHDY number 0dpShortnum} |

Sales Orders

This group of controls affect the operation of Sales Order processing and associated activities. Generally they also apply to Jobs.

|

Field |

Description |

|---|---|

|

Serial Numbering flagged parts mandatory on dispatch |

Company and System Settings. Serial number mandatory on dispatch flag. {MCDFILE.MCDSNOM boolean} If this checkbox is checked, all parts that are marked as serial numbered on dispatch in the part maintenance window will have to be provided with a serial number before they can be dispatched. Otherwise only a warning is made on dispatch when the part is appropriately marked. If you are wanting serial numbers to be printed on Dispatch Notes and Invoices, this control should be checked. |

|

Warn user during normal Sales Order item entry of low part stock |

Company and System Settings. Provide message for SO item out-of-stock flag. {MCDFILE.MCDSOMS boolean} This is a checkbox to control the warning message of low stock when a sales order line item is created or amended. This control does not apply to a Cash or Dispatch Sales Order. If set ON, you will get a low-stock message when, as a result of the entered quantity being sold the part’s projected demand quantity falls below the part minimum stock. In fact, when Physical qty. – New Order qty. – Allocated qty to WOs – Committed SO qty < Minimum stock. As this takes no account of the timing of the intended sale you should encourage the use of the Parts Available-to-sell analysis. If the part has a Planning Alias, the warning and calculations will be made with respect to the net demand of the part considered with respect to the alias part quantities. If the part (or the alias) is a Sales Order Kit item, i.e. has a ‘P’hantom part type, the Bill of Materials for the part is examined and potential shortages listed for you. |

|

Record sales intra-EC trade statistics in history |

Company and System Settings. Intra EC trade statistics maintained for sales flag. {MCDFILE.MCDIECS boolean} Sales trade statistics are, in effect, sales history records extracted for all overseas sales. There are additional fields available in sales history that can store data specifically for reporting trade statistics. If this control is checked, an additional window will be brought forward during dispatch processing in which you can record the extra data for maintaining and producing Intra-EC Trade Statistics. |

|

Quantity discount calculated compound rather than additive |

Company and System Settings. Quantity discounts calculated compound rather than additive. {MCDFILE.MCDDICO boolean} Normally on a sales order, with this control un-checked, part or customer-part quantity discounts are added to the base customer discount for the part discount class. E.G. If the part discount class is 1, and the customer discount for class 1 parts is 15.00%, and the quantity additional discount rate for 1,000 items is 4.00%, the sales order discount will be 19.00%. With this preference checked the two discounts will be arithmetically applied. For the above example the resulting discount rate will be 100 – (0.85 * 0.96 * 100) = 18.40%. |

|

Automatically reduce active production plan items on dispatch, bonding or job issue |

Company and System Settings. Automatically reduce active production plan items on dispatch, bonding or job issue. {MCDFILE.MCDPRDA boolean} Normally on sales order dispatch, bonding or job issue no reference or adjustment is made to any production plan that may have been set for the part or its alias. It can be useful, however, to automatically reduce the active production plan for the part in these circumstances to avoid the need to manually do this before running MRP again. By setting this preference active plan items for the part or its alias will take place. When this automatic process takes place active production plan entries are reduced or deleted in date order regardless of the date of the activity and the date of the production item, first for the part itself and secondly for its alias, if it has one.

|

Purchase Orders

This group of controls affect the operation of Purchase Order processing and associated activities.

|

Field |

Description |

|---|---|

|

GRN numbers for each receipt rather than session |

Company and System Settings. Separate GRN’s for each PO item receipt. {MCDFILE.MCDIGRN boolean} When Purchase Orders are received from a given supplier and Purchase Order, history records are stamped with a Goods Received Note number. Without this option set, all items received at one time by a user receiving from a given purchase order will all be combined under one GRN number. If this option is set, each individual item receipt will receive a new GRN number. |

|

Update or create Purchase Part records on receipt of Purchase Order items |

Company and System Settings. Update purchase part records from PO receipt flag. {MCDFILE.MCDPPFL boolean} When Purchase Order part line items are received, the line item details are saved in a Purchase Parts record which acts as a default set of PO line item data on the next occasion the part is purchased from this supplier. This feature is controlled with this switch. If not checked Purchase Part data will have to be manually maintained. Each line item can be individually controlled when this control is checked |

|

Update part current cost when Purchase Order prices are confirmed |

Company and System Settings. Update current costs on PO receipt flag. {MCDFILE.MCDUCFL boolean} This flag controls whether part costs are updated when you Confirm Purchase Prices or perform an Invoice Validation in the Ledgers — Accounts Payable — Invoices and Credits menu function. In both cases only the purchase history is updated with any revised costs if this flag is un-checked. Otherwise the part master material current cost is updated to reflect the confirmed Purchase Order price. If this preference is un-checked, current costs are only updated during Roll-up assembly current costs in Masters — Global Changes — Product Costing or following an Update Costs review in a maintenance window.

|

|

Make part primary supplier the last received supplier |

Company and System Settings. Update preferred supplier for part on PO receipt. {MCDFILE.MCDUPSF boolean} If checked, this control sets the part primary supplier to that of the latest Purchase Order receipt. If not checked, the primary supplier has to be manually set in parts maintenance or through purchase parts global changes. The primary supplier is most useful in organising the results of MRP and automatically generating Purchase Orders from MRP results. |

|

Tracked parts must be given a unique history reference |

Company and System Settings. Tracked parts must have unique PUHREF entered. {MCDFILE.MCDTPUH boolean} This control only applies to parts that have been flagged as batch-tracked. If checked, and only for batch-tracked parts, during the goods receipt process you will be forced to enter a unique value for the purchase history reference. This helps to ensure that you can track back to the suppliers certification batch number. |

|

Record purchases intra-EC trade statistics in history |

Company and System Settings. Intra EC trade statistics maintained for purchases flag. {MCDFILE.MCDIECP boolean} Purchase trade statistics are, in effect, purchase history records extracted for all overseas purchases. There are additional fields available in purchase history that can store data specifically for reporting trade statistics. If this control is checked, an additional window will be brought forward during goods receipt processing in which you can record the extra data for maintaining and producing Intra-EC Trade Statistics. |

Parts

This group of controls provide options relating to the creation and manipulation of parts. You should refer also to the relevant processing topics for more details.

|

Field |

Description |

|---|---|

|

Part price-to-cost as Gross Margin rather than Markup |

Company and System Settings. Show price/cost relationship as Gross Margin (NO=Markup). {MCDFILE.MCDMARG boolean} This controls whether you seek to calculate and display the relationship between part cost and selling price using a Markup or Gross Margin. If NOT checked Mark-up will apply: the calculation then makes the Selling Price = Total Cost * (100 + Auto price mark-up) / 100. If checked, Gross Margin will apply: the calculation then makes the Selling Price = Total Cost * 100 divided by (100 – Gross Margin) where Gross margin can not be greater than 99%.

|

|

Part yield in lost units per batch rather than percent rate |

Company and System Settings. Part yield in lost units per batch rather than percent rate. {MCDFILE.MCDYIEU boolean}

|

|

Part yield rate is used when calculating costs |

Company and System Settings. Part yield rate is used in calculating costs. {MCDFILE.MCDYIEL boolean} With this option checked, Product Costing and other Update Costs functions on Part costs will use any non-100% yield rate to compute a loaded cost based on the assumption that only the yield rate of parts ordered and paid for will ultimately go into inventory. For a purchased part, the cost of the part will be calculated as the actual cost divided by the yield rate. This has the effect of uplifting the cost and can be seen as taking into account losses in the transport, quality inspection or other receiving processes. For parts with a BoM that are manufactured or for outwork assemblies, the yield will similarly uplift the cost because it assumes that only the yield rate of the finished part will be useful inventory, even though the full kit quantity and process cost was consumed. |

|

Use work history to cost assemblies where available |

Company and System Settings. Use work history to cost assemblies where available (applies costing method to assemblies). {MCDFILE.MCDWOHC boolean} Normally, assembly costing of type Automatic or Make parts uses the Bill of Material and Process Route to calculate the various cost elements. If this control is set, work history will be used where it is available on the basis of the Material Costing Method set in File — System Manager — Company Details.

|

|

Do not change labour and overhead cost if no process route |

Company and System Settings. Do not change labour and overhead cost if no process route. {MCDFILE.MCDCNLO boolean} Normally with product costing, with this control un-checked, parts which are Automatic type with a Bill of Materials or Manufactured type, will have the Labour and Labour Overhead current cost values set to zero if there are no process route operations. With this system preference checked, under those circumstances the Labour and Labour Overhead values are left unchanged.

|

|

Use automatic byproduct recording and costing |

Company and System Settings. Use swarf recovery system. {MCDFILE.MCDSWAF boolean} The program has the ability to handle single byproducts in a manufacturing operation. The byproduct is identified in the parent’s part record and the quantity produced and cost implications are calculated from the parent and BoM mass values. The system is most useful in instances such as accounting for swarf. For this system to be effective, this preference must be checked. See Parts Maintenance – Planning for details. |

|

Log changes to part current costs |

Company and System Settings. Log part current cost changes. {MCDFILE.MCDPTC boolean} The program will log any changes to part current costs during normal processing. See the Part Costs History Log Listing window for details.

|

|

Part batch numbers generated as Year-Date-Serial |

Company and System Settings. Batch number generated from date. {MCDFILE.MCDBATD boolean} This controls the style of batch numbers the system automatically assigns to receipts of batch tracked parts. If unchecked the batch numbers will be numerically sequenced X000001, X000002, X000003, etc., where X is the batch number prefix set in the File — System Manager — Company Details. The sequence number can be advanced in the Document Numbers pane. If this control is checked, batch numbers are constructed numbers based on the date processing took place for the receipt of the batch. The batch number will take the form of XYDDDNN, where X is the batch number prefix, as above, Y is the Year, DDD is the day of the year (001 through 357) and NN is a numeric sequence (01 through 99). With this system you can, in effect, date the batch so that shelf life can be controlled. For example, for batches produced on 16th August 1993 (and a prefix of 9), numbers would be 9322801, 9322802, 9322803, etc., the next day’s receipts will be numbered 9322901, 9322902, 9322903, etc..

|

|

Do not auto-delete empty multi-stock locations |

Company and System Settings. Do not auto-delete multi-stock locations. {MCDFILE.MCDSTOD boolean} This control, if set, will prevent any deletion of multi-location records when they reach zero quantity, which is the normal situation. When you turn this preference OFF you will be given the option of deleting all zero (and negative) quantity location records. You may enter a value for the number of zero quantity stock locations you want to retain for each part, if more than that many exist. If you click cancel, no deletions will take place but from then on any locations falling to zero quantity will auto-delete. If you click Ok, the system will delete zero quantity locations until there remains the quantity you entered. It will delete the oldest created locations first. |

|

Maintain multi-stock location extended information |

Company and System Settings. Extended stock location and tracking data. {MCDFILE.MCDSTOE boolean} With this option checked, extended information can be entered and seen for multi-stock location records. This can be used to record additional quantities or attributes associated with a batch of parts or material. Without this option on, locations of inventory simply contain stock quantity, batch number and a flag indicating quarantine status. Extended data includes three dimensions, a unit quantity, the location creation date and comments. See Inventory, Multi-Stock Location Extended Information for full details.

|

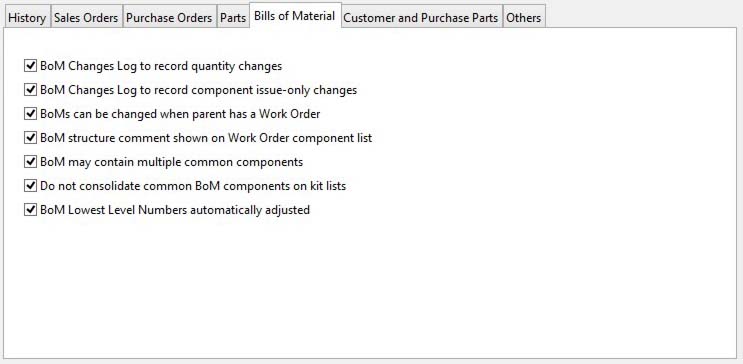

Bills of Material

This group of controls provide options relating to the creation and kitting of bills of material. You should refer also to the relevant processing topics for more details.

|

Field |

Description |

|---|---|

|

BoM Changes Log to record quantity changes |

Company and System Settings. Log BoM Quantity Changes. {MCDFILE.MCDBOLQ boolean} This control, if set, will enable the BoM Changes Log for any changes to BoM component quantities. Records are created for any component addition (type 1), deletion (type 2) and quantity change (type 3). It will increase processing during BoM maintenance. |

|

BoM Changes Log to record component issue-only changes |

Company and System Settings. Log BoM Component Issue-only Changes. {MCDFILE.MCDBOLI boolean} This control, if set, will enable the BoM Changes Log for any changes to BoM component engineering issue changes. Records are created for any component issue change (type 4). It will increase processing during BoM maintenance and when updating part engineering issue. This control operates independently to the quantity log. |

|

BoMs can be changed when parent has a Work Order |

Company and System Settings. BoM no change allowed if WO. {MCDFILE.MCDBOMW boolean} All BoM edit processes are normally prevented when a Work Order exists for the parent part. This also applies to Purchase Orders when the parent is an ‘O’utwork type part and a Sales Order when the parent is a ‘P’hantom type part. In the case of ‘P’hantom parents, parents with orders higher up the structure will also be considered as active orders and so normally prevent BoM changes. If this option is checked, only a warning is given when the parent is selected for BoM maintenance. This can override the normal protection against engineers changing structures while products are being manufactured. If this option is checked, any parents with active orders will lead to process quantity adjustments when BoM structural changes take place. |

|

BoM structure comment shown on Work Order component list |

Company and System Settings. Include BoM Structure Comment in WO component list flag. {MCDFILE.MCDBOMC boolean} Work Orders can optionally contain a listing of BoM components. The control for the printing of this list is on the WO itself. This system preference controls whether, when printed, the component listing also includes any structure comment text in the BoM.

|

|

BoM may contain multiple common components |

Company and System Settings. BoM can contain multiple common components. {MCDFILE.MCDMBOM boolean} Normally Bills of Material are a consolidated list of ingredients that make up the assembly parent part. However, it can sometimes be useful to list the same component more than once in the BoM. If this preference option is checked, you will be permitted to enter the same part number as a component in a single structure more than once.

|

|

Do not consolidate common BoM components on kit lists |

Company and System Settings. Do not consolidate common BoM components on kit lists. {MCDFILE.MCDBOMS boolean} This control will effect the way component lists are presented on Work Order Picking Lists and Work Orders. If you use ‘P’hantom type parts as components of an assembly, where components of the phantoms are the same as components in the main assembly or another phantom, these normally will be shown on lists as one item with a total quantity and only one BoM structure comment and reference. With this control option set ON, items will not be consolidated together and any structure comments and BoM references will be separately shown. |

|

BoM Lowest Level Numbers automatically adjusted |

Company and System Settings. BoM lowest level auto-adjustment in operation. {MCDFILE.MCDLLAA boolean} You can speed up Bill of Material maintenance processing by turning OFF the control for automatic BoM lowest level adjustment. Once you have turned it off, and confirmed the change with an OK, you can not switch automatic adjustment back on. It can only be set ON by running Re-organise Bills of Material in the File — System Manager — Re-set Data Files functions. “MRP processing” and the “Roll-up assembly current costs” routine can not be run when this system preference control is OFF. In addition, the BoM component parts listing report will not be accurate. |

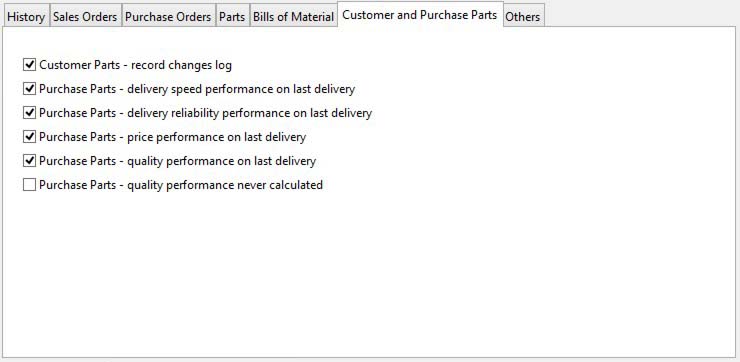

Customer and Purchase Parts

This group of controls provide options for Customer Parts and Purchase Parts.

|

Field |

Description |

|---|---|

|

Customer Parts – record changes log |

Company and System Settings. Archive customer parts file changes. {MCDFILE.MCDCPTA boolean} Changes to date in the Customer-Parts file can be logged. For this logging to be operational, this option must be set. The changes log records the new values of any field amended. It does not record the old value. For a full log therefore, you need to set the changes log feature on before any customer parts are added otherwise the full history of a record will not be maintained. When you turn the Record Changes Log on you will be asked if you would like to initialise the log. If you answer Yes, all customer part records will be scanned and any that have no log entry will be given a ‘Created’ entry in the log. This feature is useful after importing data.

|

|

Purchase Parts – delivery speed performance on last delivery |

Company and System Settings. Delivery speed performance on last delivery. {MCDFILE.MCDPPDL boolean} There are five settings for Purchase Part Performance calculating controls. These controls are applied within the Masters — Global Changes –Purchase Parts and when the Masters — Purchase Parts — Update Performance Indicators function is used. For the first 4, if checked, the respective performance indicators are calculated on the last supplier’s delivery, otherwise all the supplier’s deliveries held in purchase history will be averaged and the result used. |

|

Purchase Parts – delivery reliability performance on last delivery |

Company and System Settings. Delivery reliability performance on last delivery. {MCDFILE.MCDPPRL boolean} |

|

Purchase Parts – price performance on last delivery |

Company and System Settings. Price performance on last delivery. {MCDFILE.MCDPPPL boolean} |

|

Purchase Parts – quality performance on last delivery |

Company and System Settings. Quality performance on last delivery. {MCDFILE.MCDPPQL boolean} |

|

Purchase Parts – quality performance never calculated |

Company and System Settings. Quality performance never calculated. {MCDFILE.MCDPPQM boolean} This control, if checked, prevents update of the quality indicator during global change or when the “Update Performance Indicator” menu command is used. This may be useful to businesses that want to judge quality on factors other than historic return of supplied goods. This means that quality ratings must be manually entered in Purchase Part maintenance. |

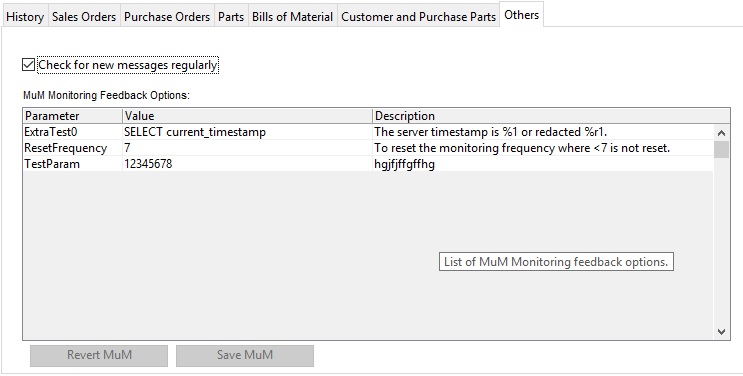

Others

This group covers other controls of a general nature.

|

Field |

Description |

|---|---|

|

Check for new messages regularly |

Company and System Settings. Check regularly for new messages flag. {MCDFILE.MCDMESC boolean} This determines whether the system checks for new user Message Box messages at every change of main menu function the user makes. If not set, the user is only notified of new messages immediately after entering their Transaction I.D.. Besides that, the user must voluntarily check his messages by entering the Message Box. Checking for messages can reduce response performance on slow networks. |

|

MuM Monitoring Feedback Options |

This enterable list provides the ability to modify and add option parameters for additional site database control of MuM Monitoring (see below for details. It has it’s own Revert MuM and Save Mum buttons below which are independent of the Revert to Saved and Save Changes main window buttons. The MuM Monitoring Feedback data is held in an otherwise unseen XMLFILE row of XMLTYPE=MTR and XMLNAME=MuM-001. |

MuM Monitoring Feedback

When MuM Monitoring is performed by Caliach Vision Support a secure connection is made to your server database and a number of tests are performed to provide a message and/or email to designated users and recipients with a message of results about the health of your database. This consists of a number of standard tests. With the Feedback test any Feedback Options are also acted upon, giving you the opportunity to add your own database-specific tests peculiar to your situation. The following are some of the controls that are available (others may be published from time to time in Knowledge Base web site articles.

![]() WARNING: The descriptions listed can not be changed other than for ExtraTestN parameters. Also note that you should not start a ExtraTestN description with the # character which is used to hide parameters from being shown on this window, because if you do use #, you will never see that entry again!

WARNING: The descriptions listed can not be changed other than for ExtraTestN parameters. Also note that you should not start a ExtraTestN description with the # character which is used to hide parameters from being shown on this window, because if you do use #, you will never see that entry again!

|

Parameter |

Value |

Description |

|---|---|---|

|

ResetFrequency |

7 or greater. |

Set this to the number of calendar days you would like MuM Monitoring to be carried out. Typycally, iCaliach Support have it set for every 7 days. You can requst it is reset to a longer period, but if you ask for less, your request will be automatically ignored. |

|

ExtraTest0 to 9 |

a SQL SELECT statement that returns a single row of data with up to 5 columns of values. Example may be SELECT current_timestamp |

This is ued to provide the MuM Monitoring report text for the results. You place a %1 in the text location where you want the column 1 result to be substituted or %r1 when it is a money value you want redacted with ■■■■ when the message is sent to a user subject to redaction. %2 or %r2 for the second column, etc. So for the statement on the left you could have soething like “The server timestamp is %1 or redacted %r1.” |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 12 Aug 2018 16:17:13.43. Class wSystemPrefs last modified 12 Aug 2018 11:53:01.