OVERVIEW

Capacity Planning gives time information obtained from existing Works Orders and Jobs. There is also an option to include MRP forecast requirements too. The analysis is based on process route operation times and work centre parameters.

NOTE: Capacity Planning is only available to those who have the manufacturing license option version of the programme

File Path

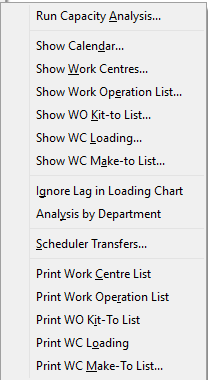

Process > Capacity Planning

This file path takes you to the Capacity Planning menu.

Run Capacity Analysis

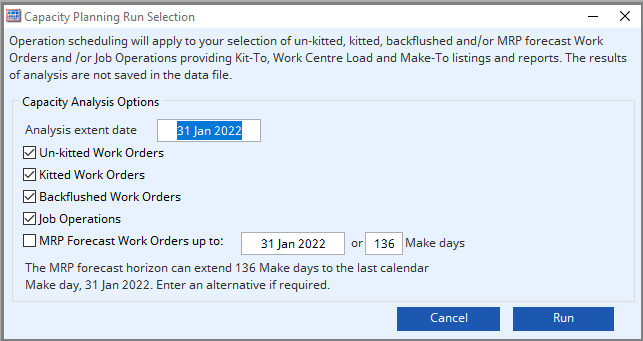

This takes you to the Capacity Planning Run Selection window.

In this window you will be offered options for the run or re-run capacity analysis.

Operation scheduling will apply to your selection of un-kitted, kitted, backflushed and/or MRP forecast Work Orders and/or Job Operations providing Kit-To, Work Centre Load and Make-To listings and reports. The results of analysis are not saved in the data file.

BUTTONS AND FIELDS

Analysis Extent Date

Enter the final date to which results are to be shown for.

Un-kitted Works Orders

Tick to include operations from normal Works Orders that are not yet kitted.

Kitted Works Orders

Tick to include operations from normal Works Orders that have been kitted

Backflushed Works Orders

Tick to include operations from Backflushed Works Orders.

Job Operations

Tick to include operations from Jobs.

MRP Forecast Work Orders up to:

Tick to include operations from MRP Forecast Works Orders up to the entered date.

If you choose to include MRP forecast Work Orders, you may limit the extent of the calendar that is included. If limited, recommended orders for completion up to the date entered will be included in the analysis prefixed with the letter M.

Or Make days

Enter the limiting number of active Make days in the calendar for MRP forecasting Work Orders.

Cancel button

Selecting this aborts the process currently in session.

Run button

This runs the capacity planning analysis. The data is collected and held in memory. When the Capacity task closes you lose the data.

SHOW CALENDAR

Selecting this option from the dropdown menu will first bring up the Capacity Planning Run Selection. Once you run capacity planning, the Make Days Calendar window opens.

This window shows a listing of all days in the MRP system’s calendar that have been marked as active Make Days. Click here for our Make Days Calendar guide.

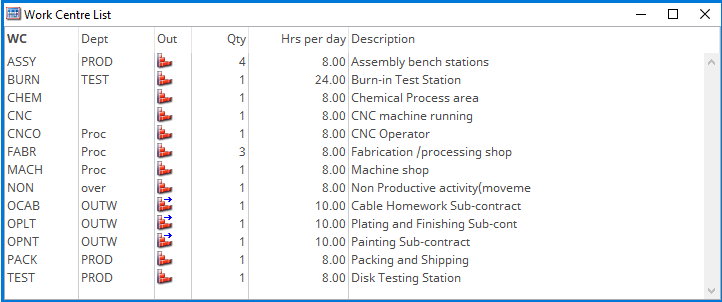

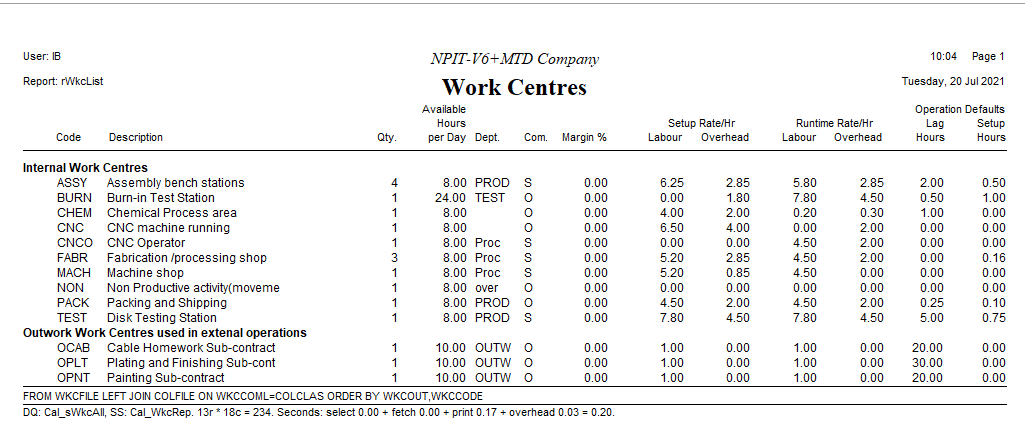

SHOW WORK CENTRES

You will find a list of all your work centres with details in this window.

Click here for Work Centre List guide.

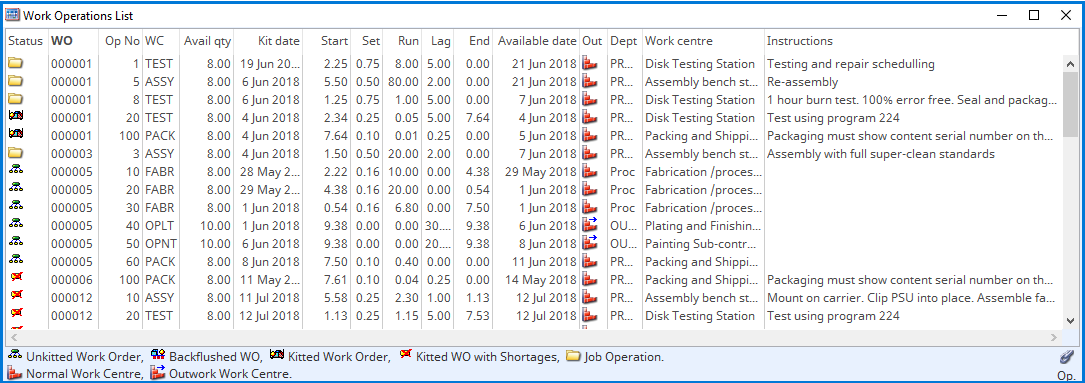

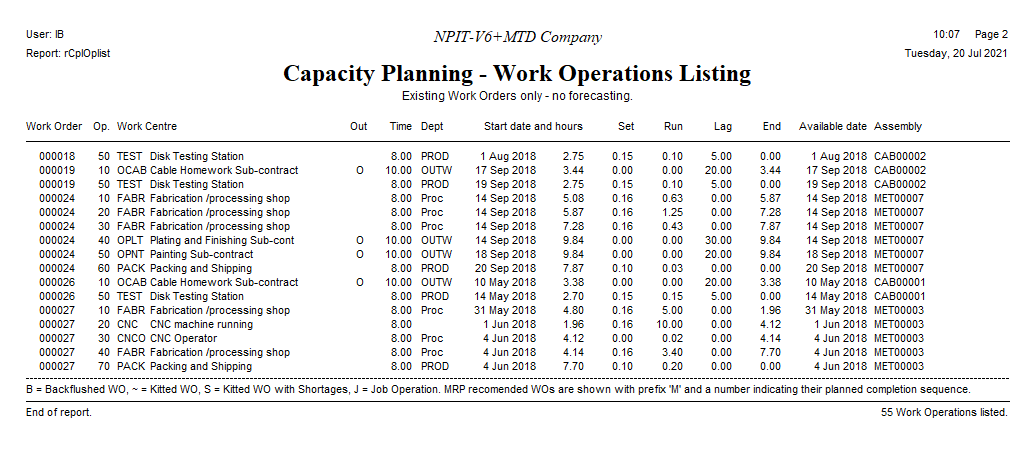

SHOW WORK OPERATION LIST

This window shows a list of all operations to be carried out on Works Orders Job Operations and, if selected, MRP forecast Works Orders.

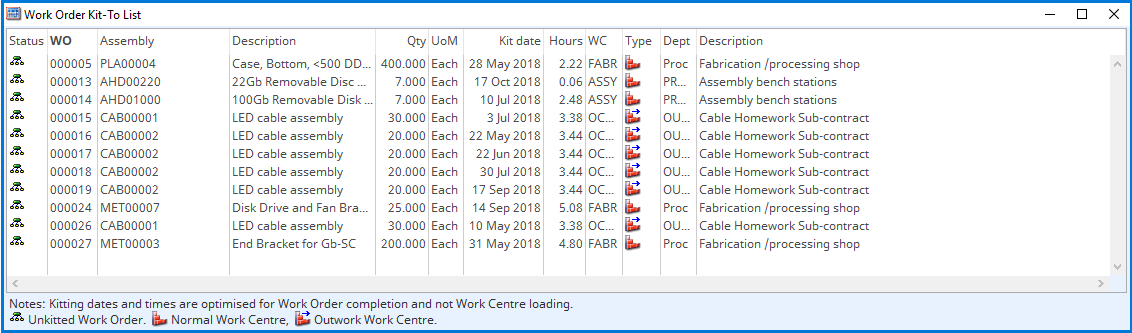

SHOW WO KIT-TO LIST

This window shows which Work Orders should be kitted and, if the sort is selected correctly, in which order, what assemblies are being manufactured and when the kits should be issued and to which Work Centre.

The Work Centre shown is that for the first operation. These dates may differ from MRP recommendations which are based on parent part lead time and not Operation times from Process Routes.

Additionally, Work Centre available hours are taken into account. However, for all orders only one Work Centre is assumed to be involved in each operation – no account is taken of the quantity of Work Centres.

If you double-click on a Work Order or Job Operation, a review window will be opened showing the Work Order or Job Operation details. Re-scheduling can then be made interactively. This is only possible, of course, with genuine Work Orders or Job Operation.

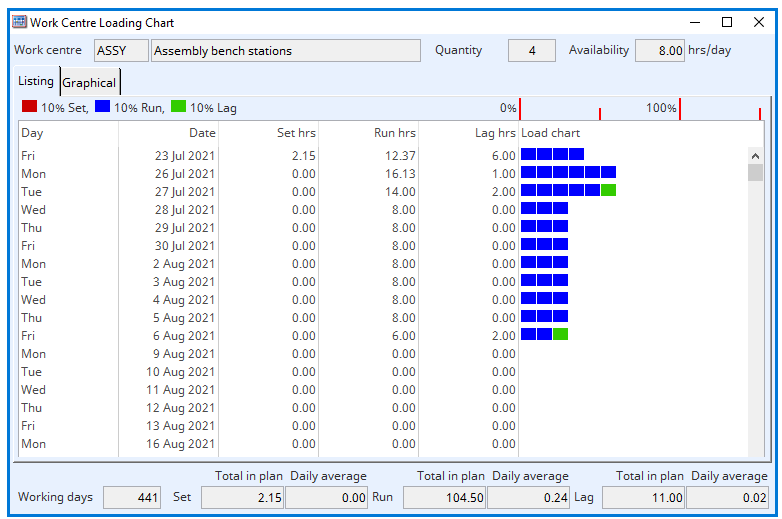

SHOW WC LOADING

This opens the Work Centre Loading Chart (this window has two tabs) and the Work Centre List window. Clicking a work centre in the Work Centre List window will show an analysis of a work centre’s operation loading over the period of activity within the calendar dates.

BUTTONS AND FIELDS

Listing tab

Work Centre or Department

This field show the Work Centre unique identifier code that is currently being worked on.

Quantity

This field shows the quantity of work centres available for planning.

Availability

This shows the hours available in each make day for the current work centre.

Loading List

Here we see the work centre loading for all working days in the make calendar.

Total Working days

This is the total number of make days in the listing.

Set – Total in plan

The total set-up hours for all operations in the forecast.

Set – Daily average

The total set-up hours for all operations in the forecast.

Run – Total in plan

Total run hours for all operations in the forecast

Run – Daily average

The daily average run hours for all operations over the working days listed.

Lag – Total in plan

The total lag hours for all operations in the forecast.

Lag – Daily average

The daily average lag hours for all operations over the working days listed.

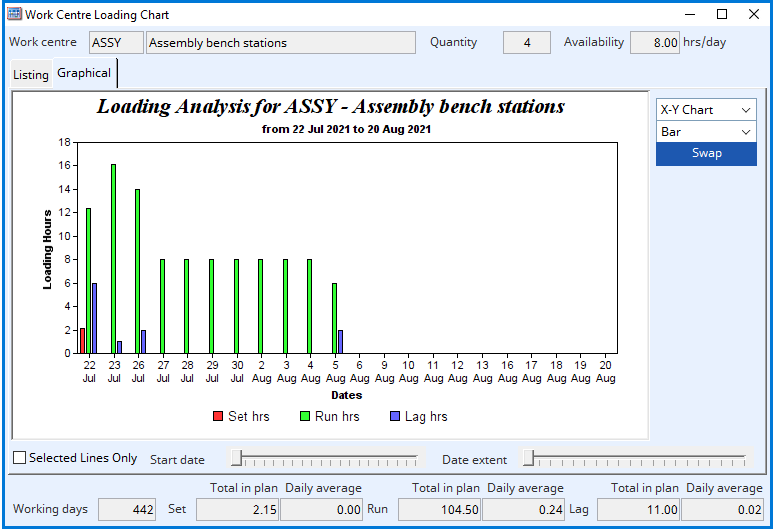

Graphical tab

This tab shows the loading in graph form.

Selected lines only box

Tick box to show only the selected dates in the list.

Start date slider

Use this to adjust the start of dates shown. The range is from the beginning date on the list up to the date 95% through the list.

Date extent slider

Use this to adjust the extent of the dates shown. The range is from 5% to 100% of the number of dates in the list.

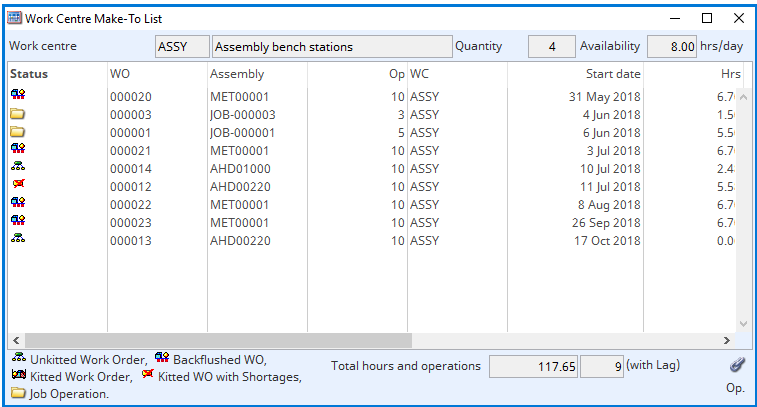

SHOW WC MAKE TO LIST

This window shows a list of all Operation activity for the currently selected work centre or department. The Work Centre list window will also open.

BUTTONS AND FIELDS

Work Centre

This is the unique identifier for the currently selected work centre. You can select the work centre by double clicking the desired work centre in the Work Centre list window.

Description

Description of the currently selected work centre.

Quantity

The quantity of the selected work centres available for planning

Available hours per day

Available hours in each make day for the selected work centre

Make-to list

This is a list of all operations that are forecast for the selected Work Centre. Typically, in order that they need to be processed.

Total Hours

Total hours for all operations shown on the Make-to list

Total Operations

Total number of operations listed.

IGNORE LAG IN LOADING CHART

Clicking this on the Capacity Planning menu will ignore all lag in the loading chart.

ANALYSIS BY DEPARTMENT

Clicking this on the Capacity Planning menu will allow you to see all work centres within a department in the Work Centre Make-To list and Work Centre Loading Chart windows.

SCHEDULER TRANSFERS

This feature provides for data transfer of Capacity information from Caliach Vision to other programs, typically Finite Schedulers.

PRINT WORK CENTRE LIST

Selecting this will display a list of all work centres with details of each. You can select how you print this page.

PRINT WORK OPERATION LIST

Selecting this will display a list of all work operations with details of each. You can select how you print this page.

PRINT WO KIT TO LIST

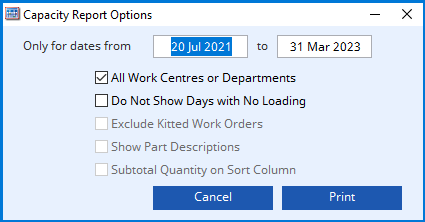

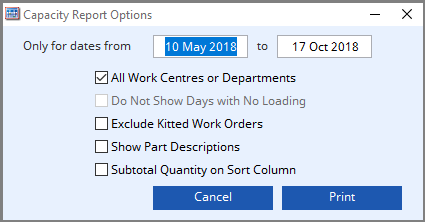

This brings up the Capacity Report Options window.

This window provides you with options when printing Wo Kit-To list, WC Loading and WC Make-To lists.

BUTTONS AND FIELDS

Date from and to

Here you can enter the dates that restricts the records selected. If left blank, data will be selected from the maximum and minimum extremes in the file. All selections criteria you enter will have to be met by each record processed.

All Work Centres or Departments

Selecting this option will provide you with a report covering all Work Centres or Departments as opposed to the currently selected. This option is not available for the WO Kit-to list reports.

Do Not Show Days with No Loading

Choose this option if you want to suppress printing of days without activity. This option is not available for WO Kit-To List or WC Make-To List reports.

Exclude Kitted Works Orders

This selection will provide you with a report omitting any Work Orders that have been kitted. This option is not available for WO Kit-To List or WC Loading reports.

Show Parts Descriptions

Provides an extra line showing part description. This option is not available for WO Kit-To List or WC Loading reports.

Subtotal Quantity on Sort Column

Ticking this box will give you a subtotal of quantities on sort columns.

Cancel button

This button will abort the process currently in session.

Print button

This will cause a report to be printed of the subject matter. Right click to change the report destination.

PRINT WC LOADING

This will bring up the Capacity Report Options window with All Work Centres or Departments already selected, the Do Not Show Days with No Loading available to select and all other options not available.

PRINT WC MAKE-TO LIST

This will bring up the Capacity Report Options window with All Work Centres or Departments already selected, the other options available to be selected excluding the Do Not Show Days with No Loading option.

This article is part of the Vision Setup Guide. Click Here to return to the Setup Guide.

Compiled in Program Version 6.00.

Class wCpLOpList (capacity planning) FP: Process > Capacity Planning