OVERVIEW

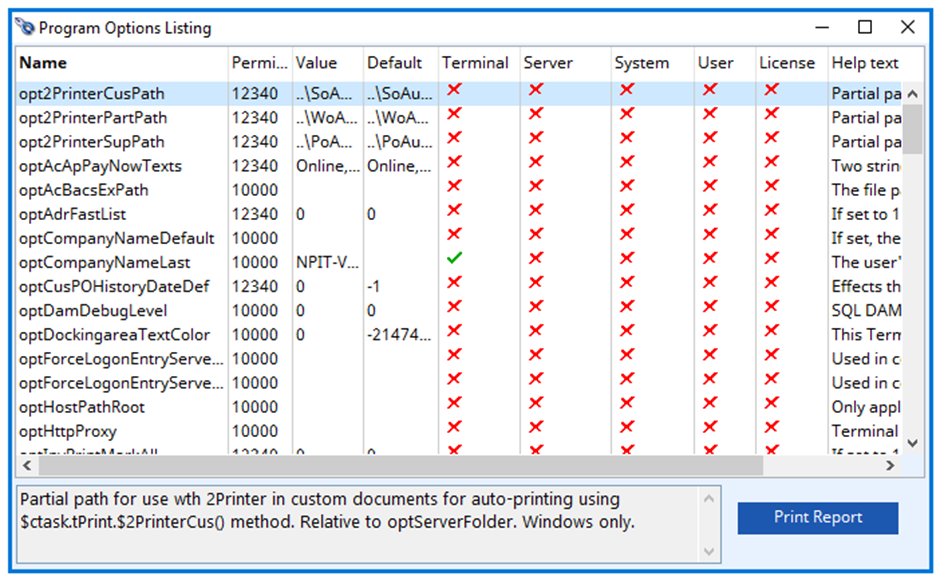

This window lists the available program options. You can drag an option line from the list and drop it into the option field in the settings or Terminal Preferences window.

File Path

File > preferences > Terminal Options > Show Option List

This file path takes you to the Program Options Listing

Each option is entered as text in the Option section of System, Group, User and Terminal settings. In addition, some options are License options that can only be activated when stated on your License Activation document. Options can be translated from CaliachMRP 4000 strings using the list below.

Each option has a set of privileges which determine where the option can be entered, and these are shown on the right.

| Key | Name | Description |

| T | Terminal | Terminal settings are held in the Terminal.inf structured text file in the Terminal directory and set workstation characteristics. |

| S | Server | Server settings exist when the Terminal.inf file is in an Terminal directory in the same directory as the data file. If this is the case it takes precedence over a Terminal.inf file in a local Terminal directory. |

| Sy | System | These options are held in the data file and apply to all users of the system and override any other option entries. |

| U | User | These options are entered in a User or Group record and apply to an individual user or members of groups. |

| L | License | Entered at the time of License Authentication. These can be viewed in . File — Advanced — License |

Wherever options can be added, there is a Show Options List button. Click on this to view a window containing the available options with the appropriate privileges. You can drag and drop these options into the option text area you are maintaining.

| Name | Privileges | Description |

| opt2PrinterCusPath | T, S, Sy, U | Partial path for use wth 2Printer in custom documents for auto-printing using $ctask.tPrint.$2PrinterCus() method. Relative to optServerFolder. Windows only. |

| opt2PrinterPartPath | T, S, Sy, U | Partial path for use wth 2Printer in custom documents for auto-printing using $ctask.tPrint.$2PrinterPart() method. Relative to optServerFolder. Windows only. |

| opt2PrinterSupPath | T, S, Sy, U | Partial path for use wth 2Printer in custom documents for auto-printing using $ctask.tPrint.$2PrinterSup() method. Relative to optServerFolder. Windows only. |

| optAcApDocRefUnique | Sy | Set to 1 or 2 to respectively warn the user or prevent a non-unique document reference for a supplier when entering an invoice or credit note. |

| optAcApMemoStop | Sy | If set to 1, non-approved credit memos on A/P debit transactions will not be included in pay selected and a warning will be given if allocated. If set to 2, allocation will be prevented. |

| optAcApPayNowTexts | T, S, Sy, U | Two strings seperated by a comma. These will be used to set the Document Ref. and Comment of the payment transaction. User the token % to imbed the original transaction document reference. |

| optAcBacsExPath | T | The file path for the Bank Cheques BACS export. The directory path must exist. The file will be created or overwritten. Otherwise the user will be prompted as normal. |

| optAcBacsPayDays | Sy | The default BACS export payment days from today in working days based on the Buy Calendar. |

| optAcClearingUsersAP | Sy | A comma-delimited list of user ids that have permission to clear AP transactions on supplier accounts. (CalMRP = 4024) |

| optAcClearingUsersAR | Sy | A comma-delimited list of user ids that have permission to clear AR transactions on customer accounts. (CalMRP = 4023) |

| optAcCreditsAutoClear | Sy | Set to 1 if Credit Note transactions in the Accounts Receivable ledger should not be automatically cleared when created. (CalMRP = 4007) |

| optAcForceComments | Sy | Set to 1 or 2 to respectively warn or force a comment to be entered for an accounts transaction. |

| optAcForceDocRef | Sy | Set to 1 or 2 to respectively warn or force a document reference to be entered for an accounts transaction. |

| optAcNoMixedCur | Sy | Set to 1 if AR and AP accounts can not have mixed foreign currency transactions. A local currency account can. |

| optAcRetroJouUsers | Sy | A comma-delimited list of user ids that have permission to create Retrospective Journals. |

| optAdcCusAutoNew | Sy | A comma-delimited list of Contact Id numbers (ADCID), each time a new customer is created, a duplicate of those contacts are created for the new customer’s default address including associated document links. Telecoms are copied from new customer/contact. |

| optAdcDeaAutoNew | Sy | As above, for new marketing records. |

| optAdcSupAutoNew | Sy | As above, for new suppliers. |

| optAdlSoInvPrint | Sy | If set to 1, after a SO is marked as printed, the invoice address and contact will change to any INV link setup. Resetting the printed flag will set them to SO link, if any. |

| optAdrFastList | T, S, Sy, U | If set to 1, the listing in the Address Select window will contain sparse information but will be faster to build. Suitable where master records may have hundreds of addresses. |

| optBoMAllowNegQty | Sy | If set to 1, 2, or 3 negative BoM Component Quantities will be permitted. 1 = permit but ignore net negatives. 2 = permit and message net negatives, 3 = permit and auto-adjust net negatives. For details on the use of this option see the end of Bills of Material Maintenance topic. |

| optBoMCommonParts | Sy | In situations where a BoM file contains components that are used very commonly, slow maintenance processing can result. Any parts entered here will be dealt with in a special manner. Parts are delimited with *?* and a range is denoted with *-*. (CalMRP = 4008) |

| optBoMQtySumUoM | Sy | BoM Maintenance will have an extra field of the sum of Kit quantities with stock UoM equal to text entered here. It is case-insensitive. Good for food or chemicals where the product weight or volume is the sum of kit quantities. See also optWOQtySumUoM. |

| optBoMUpdatesIssue | Sy | If set to 1, when saving changes to a BoM (not during delete or component mass change operations) the assembly part issue is automatically updated and the update issue window is opened before saving. If set to 2 part master issue change is also disabled. |

| optBoMZeroQty | Sy | If set to 1, Bill of Materials quntity for a component can be zero. For details on the use of this option see the end of Bills of Material Maintenance topic. |

| optCommissionLogCosts | Sy | If set to 1, when logging commissions, costs will be recorded regardless of calculation method. Otherwise, only when the cost is relevant to the calculation method. |

| optCommissionRoyalty | Sy | If set to 1, when applying agents on a SO, Job or Invoice, agents entered in the PTMUSE4 parts field are added to the agent list. |

| optCompanyNameDefault | T | If set, the user will receive a warning if they attempt to log on to a Company Name logon that does not conform. This is available to warn users when they inadvertantly choose a backup or play-data set. |

| optCompanyNameLast | T | The user’s last logon company name. This is automatically set in Terminal.inf and used to re-select it as the default at the next logon, when optCompanyNameDefault is not set. |

| optDamDebugLevel | T | SQL DAMs (Data Access Modules) can create Debug logs to record internal errors. If this option is set to between 1 and 5 a text file named DamDebug.txt will be created in the same folder as Vision.lbs. 1= No debugging but is available, 2= Base level, 3, 4 and 5 are escalating levels of refinement. |

| optDatafilePathDefault | T | The default file path for the normal datafile. If set a warning will be given when you attach to any other data file. Only appropriate to set in Terminal.inf on a local workstation. This option was made obsolete in V5.00. |

| optForceLogonEntryServerN | T | Used in conjunction with optUsernameServerN and optPasswordServerN. N=1 for MySQL and 2 for PostgreSQL. Forces the server logon name and password where password entry by the user can be forced. |

| optHostPathRoot | T | Only applies for SQLite main database. If set, the Host database file path for SQLite will be prefixed with the contents, when constructing the path. This is useful where users see a server location differently, for instance when mappings are different. |

| optHttpProxy | T | Terminal only option. The IP address of an HTTP proxy server, followed by a : then the post (e.g. 62.112.211.46:3128). If this option is set all HTTP traffic will be via this proxy server. Proxy Servers are often used in commercial networks to route access to the internet via a safe gateway that restricts internal network users to only approved sites. They can also be used to mask your identity to the end server delivering content. |

| optInvPrintMarkAll | T, S, Sy, U | If set to 1, when printing an Invoice it is marked as printed regardless of the report destination. |

| optJobEstimateText | T, S, Sy, U | Text that will be applied by default to the Estimating Notes of a new line item on an Estimate or Job. The syntax <CR> is replaced by a return character for multi-line text. |

| optJobInheritsUserFields | Sy | Set to 1234, or any combination, will cause those Job user defined fields to be inherited from the customer fields. |

| optJobNoEngChange | T, S, Sy, U | If set to 1, users will be prevented from adding a part which has Engineering-in-Progress set to a Estimate or Quotation, rather than just being given a warning. |

| optJobProcessListField | T, S, Sy, U | An alternative to Job item description displayed when a line is selected in the part processing quantity drill-down listing. A valid calculation can be entered using fields from the Job Header and Line Item files. E.G. JOBCOMM to show order comments. |

| optJobSnTracking | Sy | If set to 1, when closing a Job, any parts set to be Serial Number Tracked on dispatch (PTMSNT is set) will have a SN Tracking record created for them. |

| optLangLocalPriority | Sy | If set to 1, non-English language updates to not overwrite local Custom/Translate.df1 localisation texts created. |

| optLangSwapBlockUsers | Sy | Language Swap blocked users and groups. Language code=User,Group list;… list of languages and users or groups blocked from using them. Applies also to Administrators. If no language code is set block applies to all languages. e.g. fr=AA,GM;th=AA,Sales See Introduction to the Language Swap System for more details. |

| optLinkCustomEntry | T, S, Sy, U | The option value should be the name of a custom window, which is case-sensitive. When holding down the Ctrl key, this custom window will replace the normal generic Confirm Linked File dialogue to enable alternative link entry. |

| optLinkFilesRoot0 to 9 and A to Z | T | Terminal preference only. Set to the root path for linked files of volume 0. Similar options volume 1 through 9 and A through Z. |

| optLinuxPSAutoCommand | T | Linux Only. The automatic system command applied to send the Postscript file to the printer. When omitted or blank command is ‘ls’. Actual command is ‘ls PostscriptFilePath’. If you want to use the CUPS printing system, a suitable command may be ‘qtcups’. |

| optLinuxPSTemplateFile | T | Linux Only. If used and not blank this is the filename of the Postscript file template file which must be in the Terminal directory. When used the Postscript output is embedded in place of the characters $*$*$*$*$*$. |

| optLocaleDefault | T | This teminal option is set by the Program Language sub-menu function Set the Current Language to Default. The value must be a supported Locale, e.g. en. The program will subsequently start in that language. |

| optMarketDefaults | T, S, Sy, U | A comma-delimited list of field default values for new Marketing records in the form of ADCDEAR=Sir,ADCSALU=Mr. Can accept any field in DEAFILE, ADRFILE, ADCFILE and DEEFILE. Date values are days from or before today, e.g. DEACALL=5 will make the Callback Date 5 days ahead. |

| optMarketSyncAvoid | T, S, Sy, U | Set to a number to suppress the customer synchronisation of particular codes. 1 = Index code 1, 2 = Index Code 2, 4 = Mkt. Project, 8 = Addresses and Contacts. For a combination, add these numbers together. 0 = all codes will be synchronised. |

| optMonitorShowPassUsers | Sy | A comma-delimited list of user ids that have permission to use the Show Password button on the Monitor window. |

| optMRPLoopMax | Sy | MRP processing requires numerous recursive list manipulations and if data is corrupt or damaged the process can hang. There is therefore a limit set for the number of recursive loops that can be performed. This defaults to 100. This option allows you to control this in debugging situations. Set to 10 or greater, otherwise the default will apply. |

| optNCRAutoMovements | Sy | Set of stock movement type characters that will cause an automatic Non-Conformance Report regardless of whether stock is quarantined. The following can be used in any order or number: BDHW for SO Return, PO Return, Outwork Return and Scrapped from WO. |

| optNoShowCredit | T, S, Sy, U | If set to 1, the Net Available Credit value for the customer will not be displayed on the sales dispatch window list. (CalMRP = 4000) |

| optNoShowKitCost | T, S, Sy, U | If set to 1, the kitted cost fields will not be displayed on the Work Order selection dialogue box. (CalMRP = 4001) |

| optODBDatafile0 to 9 and A to Z | T | Obsolete in V5 onwards. Omnis Data Bridge data file configuration. 0-Z alternate data files. Option value must be: DatafileODBName,KeywordODBName,IPAddress:Port,DirectPath |

| optPasswordServerN | T | Used in conjunction with optUsernameServerN and optForceLogonEntryServerN. N=1 for MySQL and 2 for PostgreSQL. Forces the server logon name and password where password entry by the user can be forced. |

| optPOBomComments | T, S, Sy, U | Set to the number of BoM Structure Comments characters that should be printed extra on a Purchase Orders when outwork kits are listed. |

| optPODefaultIndivText | Sy | Set to 1 will cause Part Purchase individual text to be a default description when parts are added to a Purchase Order line item and no Purchase Part description is available. If not set, the text will be printed on POs as additional text. (CalMRP = 4009) |

| optPOFromSOInheritMrp | Set to 1 will cause the SO line item Ignore for MRP flag to be copied to the resulting PO. | |

| optPOInheritsUserFields | Sy | Set to 1234, or any combination, will cause those PO user defined fields to be inherited from the supplier fields. |

| optPOJobOpUsers | Sy | List of system users permitted to add Job Operation items to a Purchase Order. Each User Id must be followed by a comma, including the last. If blank, any user with privileges can add these items to a PO. |

| optPOKanBanNoChoice | T, S, Sy, U | If set to 1, the user will be forced to accept the best ranked purchase part record. If set to a text, then the record with that text (case-insensitive) in the notes will be chosen, then by rank. |

| optPONoEngChange | T, S, Sy, U | If set to 1, users will be prevented from adding a part, which has Engineering-in-Progress set, to a RFQ or Purchase Order, rather than just being given a warning. |

| optPONonPartUsers | Sy | List of system users permitted to add non-part items to a Purchase Order. Each User Id must be followed by a comma, including the last. If blank, any user with privileges can add these items to a PO. |

| optPOOutOpAllWCs | Sy | If set to 1, Work Order or Job operations can be raised on a PO even though they are not for Outwork Work Centres. |

| optPOOutOpNoUpPro | Sy | If set to 1, times on process route operations are not changed when WO outwork operations, received from a PO, have their prices confirmed. |

| optPOOutShortReceipts | Sy | If set to 1, Purchase Orders containing Outwork Assembly items with Shortages on file can have items received. The default is not to permit receipts when shortages exist as this can lead to orphaned shortages. (CalMRP = 4020) |

| optPOPartTextDupl | T, S, Sy, U | If set to 1, consecutive common part items on RFQ and PO documents will not suppress part individual and/or standard purchase texts. I.E. they will repeat. |

| optPOPrepDateChange | Sy | If set to 1, PO preparation history will be recorded for due date changes. |

| optPOPrintMarkAll | T, S, Sy, U | If set to 1, when printing an RFQ or PO it is marked as printed regardless of the report destination. |

| optPOProcessListField | T, S, Sy, U | An alternative to PO item description displayed when a line is selected in the part processing quantity drill-down listing. A valid calculation can be entered using fields from the PO Header and Line Item files. E.G. POHOPCO to show order comments. (CalMRP = 4027) |

| optPOReceiptAddUsers | Sy | List of system users permitted to add part items to the receipt of PO items list. Each User Id must be followed by a comma, including the last. Drag parts from Scratchpad and drop onto receipt list. |

| optPOReceiptEarly | T, S, Sy, U | If set to a non-zero integer, PO receipts received earlier than that number of days earlier than the due date (or later if negative) will trigger a user warning. |

| optPOReceiptLate | T, S, Sy, U | If set to integer greater than zero, PO receipts received more than N days later than the due date will trigger a user warning. |

| optPOReturnBackorder | T, S, Sy, U | Set to 0 or 1. Determines the default state of the Backordered checkbox when returning goods to suppliers. |

| optPORfqToPoInitFix | T, S, Sy, U | If set to 1, the creator user ID is not updated to the current user when an RFQ is converted to a quote. Set this to manage PO authorisation using RFQ preparation. |

| optPOShowCostCtrList | T, S, Sy, U | If set to 1 and you have Ledgers licensed, PO line item maintenance Additional tab pane will list all cost centres for the account group selected. |

| optPOShowSupComment | T, S, Sy, U | If set to 1, any supplier comments are shown when creating a new PO. If set to START,END where START and END are alphanumeric string markers anything contained between the markers in the comments are shown. START and END are both optional. |

| optPOUserValueLimits | Sy | User’s PO maximum value comma separated list made up of UserID, local currency value pairs. E.G. SYS,1000,CR,500 means user SYS is limited to 1000 and CR is limited to 500. Users not listed have no limit. |

| optPOWoOpUsers | Sy | List of system users permitted to add Work Order Operation items to a Purchase Order. Each User Id must be followed by a comma, including the last. If blank, any user with privileges can add these items to a PO. |

| optPartConComcUsers | Sy | A comma separated list of User Ids for those users permitted to maintain special country group commodity codes. For more details see the Country Group Commodity Codes window help. |

| optPartCostNoUpdate | Sy | If set to 1, when a part has the Prohibit auto-cost-update control on, part costs are not updated during Confirm PO Prices or Invoice Verification. |

| optPartDescSubField | T, S, Sy, U | To substitute an alternative part field for the description field in certain lists in windows. Enter the field name. The following windows are affected: Assembly Details – kit components only Bills of Material Maintenance – components only Engineering Data Maintenance Keyword Result Master Production Schedule MRP Purchase Order Recommendations – default part item description only when creating PO Part Processing Analysis Part Quality Assurance Regime Maintenance Purchase Order Line Item Maintenance – default part item description only Purchase Parts Maintenance Quality Results Data Maintenance Stock Control Activity Stock History Listing |

| optPartIndivOheadValue | Sy | If set to 1, part individual overhead will be a value rather than a percent rate. If zero the system default rate will apply. |

| optPasswordWarn | Sy | Set to the number of days (default if not set is 15) before password expiry that a user will receive a warning after login. |

| optQAInheritPhantoms | Sy | Set to 1 if QA Part Regimes inherit phantom component QA regimes multi-level. For details on the use of this option see the end of Part Quality Assurance Regime Maintenance topic. |

| optQuoteDeliveryText | T, S, Sy, U | Text that will be applied by default to the Delivery terms of a new line item on a quotation. The syntax <CR> is replaced by a return character for multi-line text. |

| optRepDestIndivid | T, S, Sy, U | A comma separated list of Report Destinations to which documents will be printed individually. Normally, multiple document (such as Invoices) print runs are a single output. However, for some report destinations, such as Email, this may be inappropriate and documents need to be printed individually. Without this option HTML, PDF, Email, Stored destinations force individual printing. |

| optRepDestMarkDocs | T, S, Sy, U | A comma separated list of Report Destinations to which documents are flagged as printed when printed to those destinations. This applies to SOs, Invoices, POs, WO Pick Lists and WOs. optSOPrintMarkAll, optInvPrintMarkAll, optPOPrintMarkAll, optWOPickPrintMarkAll and optWOPrintMarkAll options respectively override this option. If this option is not used the default marking report destinations are Printer, Email and Stored only. |

| optServerFolder | T | The full path to the folder on the server where common additional files can be found. This acts as the root to the location which may be appended by a Company folder in the Logon Settings. The full path is used to locate supporting files: Extras, Custom, ProgUser.db, ProgSyst.db, etc. |

| optSOAddConfigParts | Sy, U | If set to 1, parts can be added to the parts list of the standard SO Configurator using drag and drop from the parts ScratchPad. |

| optSOAddRefAnalysis | T, S, Sy, U | Set to 1 for Sales Orders to show Additional Ref. rather then Customer Ref. in the Processing Analysis listing. (CalMRP = 4006) |

| optSOBatchComments | Sy | Set to the number of Stock Location Comments characters that should be entered extra in Sales History SAHBATC when batches are selected. Uses String s4391 to format text, as opposed to the normal s0516. |

| optSOBatchNosInDesc | Sy | If set to 1, Batch Numbers of tracked parts will be appended to the Sales History description and show on invoices. (CalMRP = 4016) |

| optSOCrefCheck | T, S, Sy, U | If set to 1, a check is made for SOs and Jobs that the customer reference is unique for that customer in current open documents. If not a warning is given. If set to 2, dispatched sales history is also tested. |

| optSODefaultIndivText | Sy | Set to 1 will cause Part Sales individual text to be a default description when parts are added to a Sales Order line item and no Customer Part description is available. If not set, the text will be printed on SOs as additional text. (CalMRP = 4010) |

| optSODisableSolninv | Sy | Set to 1 will disable the No Invoice on Dispatch checkbox on Sales Order Maintenance. This will NOT prevent it being inheritted from the customer’s default, this option in-effect enforces it. |

| optSODisableSoldesc | T, S, Sy, U | If set to 1 will cause the line item description entry field to be permanently disabled for the user (to force use of a custom text configurator). |

| optSODispatchAllNet | T, S, Sy, U | If set to 1, the option will effect the Dispatch All function in the SO Dispatch window and cause the dispatch to be loaded with up to the physical quantity available for the order, otherwise the total ordered quantity is set which can cause inadvertent negative stock. |

| optSODNAllwaysPrint | T, S, Sy, U | If set to 1, the Dispatch Note will always print on dispatch confirmation. Normally, the user will be asked whether a Dispatch Note is needed. (CalMRP = 4012) |

| optSODueDateDays | Sy | Set to control the default Delivery Due Date when first adding a line item to a Sales Order. 0 or blank = next make day to today, 1 or -N = current make day (or next if today is not a make day). N where N > 1 = N make days beyond the current make day. (CalMRP = 4014) |

| optSOEditDeli | T, S, Sy, U | Set to 1 will enable the Delivery Terms field for modification even when a Quotation is confirmed as a Sales Order. |

| optSOHistoryDateDef | S, Sy, U | Effects the default From Date on the SO History Listing window. The default is 6 months back from today. If set negative the date will be cleared, a positive value gives that many months of history. |

| optSOInheritsUserFields | Sy | Set to 1234, or any combination, will cause those SO user defined fields to be inherited from the customer fields. |

| optSONoEngChange | T, S, Sy, U | If set to 1, users will be prevented from adding a part to a Quotation or Sales Order which has Engineering-in-Progress set, rather than just being given a warning. |

| optSONoNTypePartWarn | T, S, Sy, U | If set to 1, the warning message presented when a non-stock type part is added to a SO or Job will be suppressed. |

| optSOPartTextDupl | T, S, Sy, U | If set to 1, consecutive common part items on Quote, SO, Est., Jobs, Dispatch and Invoice documents will not suppress part individual and/or standard sales texts. I.E. they will repeat. |

| optSOPickSort | T, S, Sy, U | Sales Order Picking List sort order, when printed. 0 = Line item, 1 = part Preferred Location then by line no. For SO Kite items, when encountered, 0 = part number, 1 = part Preferred Location then by part number. |

| optSOPickStoComments | T, S, Sy, U | Set to the number of Stock Location Comments characters that should be printed extra on a Sales Order Picking List when multi-locations are shown. |

| optSOPrepDateChange | Sy | If set to 1, SO preparation history will be recorded for due date changes. |

| optSOPrices3Decimals | Sy | Set to 1 if you wish to have Selling Prices rounded to 3 places of decimal. Normal is 2. Files Classes must also be set to 3dp. This option only controls the program rounding functions. (CalMRP = 4005) |

| optSOPrintMarkAll | T, S, Sy, U | If set to 1, when printing a Quotation or SO it is marked as printed regardless of the report destination. |

| optSOProcessListField | T, S, Sy, U | An alternative to SO item description displayed when a line is selected in the part processing quantity drill-down listing. A valid calculation can be entered using fields from the SO Header and Line Item files. E.G. SOHCOMM to show order comments. (CalMRP = 4028) |

| optSOPromoPriceWarn | T, S, Sy, U | If set to 1 or YES, the user gets a warning if the customer part, or part if there is none, is set for promotional pricing and the dispatch date is not within a promotion range. |

| optSOReturnRMA | Sy | If set to 1, on a SO return, a RMA-NNNNNN part will be duplicated from part entered in PTMUSE3 and added to new backordered SO. Can be switched off in Complex Return window. If set to 2, default No Credit Note and item backordered will have zero price. See Returns from Dispatched Sales Complex Options. |

| optSOReturnSubstitute | Sy | If set to 1, the stock parts can be added to a complex SO return. These are not added to sales history but stock transactions take place and this therefore provides for return part substitution. |

| optSOReturnSupplier | Sy | If set to a valid supplier code, you will be able to create PO or WO valuation history when returning dispatched goods. PO history will be assigned to this supplier. |

| optSOShowCusComment | T, S, Sy, U | If set to 1, any customer comments are shown when creating a new SO or Job. If set to START,END where START and END are alphanumeric string markers anything contained between the markers in the comments are shown. START and END are both optional. |

| optSOTradeDefDisp | Sy | A comma separated row of default trade terms for a dispatch SAHDEL,SAHTRAN,SAHTRM,SAHORIG. If the country is omitted your country is applied. Typically 1,10,3, |

| optSOTradeDefRet | Sy | A comma separated row of default trade terms for a return SAHDEL,SAHTRAN,SAHTRM,SAHORIG. If the country is omitted your country is applied. Typically 3,26,3, |

| optSerialNoPrintInvoice | Sy | If set to 1 or YES, the printing of serial number information on Invoices, Credit Notes or CBD Invoices (but not Dispatch Notes) will be disabled. (CalMRP = 4022) |

| optSessionIdleMaxMins | Sy | Maximum session idle time in minutes before forcing a logoff. Minimum orf 5, maximum 720, default 240. |

| optSessionLogMaxDays | Sy | The maximum age in days of USLFILE table rows are automatically deleted. Minimum 10, maximum 365, default 90. |

| optSqlPgExplainOptions | U | PostgreSQL EXPLAIN options. See PostgreSQL documentation. Google “postgresql explain” for details. The parentheses are added automatically. E.G. ANALYZE TRUE,FROMAT JSON |

| optSingleUserDelaySecs | S, Sy, U | Single-user other user delay logout in seconds. Minimum 60, maximum 600, default 180. |

| optStockBatchDateWarn | Sy | If set to 1, a user warning is given on batch selection at the time of dispatch when date-based batch numbers are older than number of days set in PTMUSE2. This enables an expired batch to be identified so that expired stock is not shipped to customers. (CalMRP = 4017) |

| optStockBatchNoManual | Sy | If set to 1, the user is permitted to enter a Batch Number for batch tracked items received from a Purchase Order or received from a Work Order. The number must be unique and have a different prefix character to that currently set in the Company Details. (CalMRP = 4018) |

| optStockBatchWindowOff | T, S, Sy, U | If set to 1 and when Extended Stock Information system preference is on, the normal multi-location data entry window does NOT open during transactions. |

| optStockCopyComment | Sy | If set to 1, any change to the comments of a stock location will be transferred to the comments in existing tracking records for that batch, rather than just being applied to any future tracking records. |

| optStockCtrlVarWarn | T, S, Sy, U | Set to a non-zero % of physical for which a stock control activity and stocktake result triggers a user warning. If physical is 1 or less any quantity will trigger the warning. |

| optStockEditDate | T, S, Sy, U | If set to 1 the date field in the extended multi-stock locations can be edited, otherwise it is set as the date the stock location entry was created and cannot be changed. This provides for shelf life. (CalMRP = 4026) |

| optStockFirmAlloc | Sy | If set to 1, multi-location parts will be pre-allocated with a location code to indicate the document (P,J,S,W) on which they are required. Batches will be split if needed (regardless of the part’s split batch control). For more details of the operation of this option see the Location and Batch Assignment window help. There is a useful Custom Function that can be used with this option set: Firm Allocation Cleanup |

| optStockNegativeWarn | T, S, Sy, U | Set to 1 if you wish to have the user receive a warning when a parts physical quantity goes negative during a stock transaction. (CalMRP = 4015) |

| optStockPurchRecAuto | Sy | On Purchase or Work Order receipt, multi-stock location parts will be auto-preassigned with preferred location existing or new batches. 0 = No auto-assignment, 1 = PO Receipt auto-assignment, 2 = WO Receipt auto-assignment, 3 = PO and WO Receipt auto-assignment. Does not apply if optStockFirmAlloc=1. |

| optStockScrapRework | Sy | Used to enable a Scrap and Rework tab pane on the Stock Control window. It takes 3 parameters separated by commas: MAIN,SCRAP,REWORK. MAIN is optional. SCRAP is the doc. ref. and REWORK a location. For details see the Stock Control Activities window help. |

| optSystemEditTimer | T, S, Sy, U | Set to the seconds (if 0 system overrides to 240) during an on-window edit process after which a forced cancel is initiated with a 10 sec warning. If the warning is cancelled, a further period is given. Normal is 240 + 10 + 120 + 10 = 380 secs. (CalMRP = 4021) |

| optTaxListInCurrency | T, S, Sy, U | Set to 1 if you wish tax breakdown lists on documents to read in the currency of the document rather than local currency. |

| optTaxOnUpliftValue | Sy | List of TaxRegime,UpliftPercent, separated by commas, of those tax regimes where the tax is calculated on the goods value uplifted by a percentage. |

| optTimeShowSecs | T, S, Sy, U | Set to 1 or 2 if you wish time and datetime data is displayed with seconds (1) and centiseconds (2) added. Warning: columns in lists and reports may overflow. Option only becomes effective at logon. |

| optUsernameServerN | T | Used in conjunction with optPasswordServerN and optForceLogonEntryServerN. N=1 for MySQL and 2 for PostgreSQL. Forces the server logon name and password where password entry by the user can be forced. |

| optUserStoreWinSet | Sy | Set to 1 if you want window position/size and list configurations stored in the user settings, and re-read when user logs in. Useful for server-loaded running Vision, such as some Mac server configurations. |

| optWOBackYieldScrap | Sy | When this is set to 1, during the backflush of a WO the system defaults any yield loss as scrapped so that the kit quantity accommodates yield. This is not suitable for MRP scheduled orders because MRP will schedule the yield into the WO quantity and therefore using this option will duplicate the yield losses. |

| optWOCanAddParent | Sy | Set to 1 when you wish to permit the WO assembly part itself being added as an extra part to a Backflushed WO. This provides for partial re-processing. |

| optWODefaultIndivText | Sy | Set to 1 will cause Part Works individual text to be a default comment for all Work Orders for the Part. If not set, the text will be printed on WOs as assembly text. (CalMRP = 4011) |

| optWODefPrintOnCreate | T, S, Sy, U | If set to 1 when you create a Work Order the print option will be selected. (CalMRP = 4025) |

| optWOFromSOInheritMrp | Sy | Set to 1 will cause the SO line item Ignore for MRP flag to be copied to the resulting WO. |

| optWOHistOpCom | Sy | Set to 1, causes pop-up operation history comment entry for each Shopfloor or Log WO Performance entry. Set to 2, for the same in Receive WO and Backflush WO, additionally. Use optWOHistOpComment for default comment text. |

| optWOHistOpComText | Sy | The default text for work operation history comments. Used in conjunction with the optWOHistOpCom option. The syntax <CR> is replaced by a return character for multi-line text. |

| optWOHistoryEditPlan | T, S, Sy, U | If set to 1, the planned times in Log WO Performance can be edited or cleared. Typically useful where you have alternative route operations and do not want un-processed operations costed. |

| optWOInheritsUserFields | Sy | Set to 1234, or any combination, will cause those WO user defined fields to be inherited from the assembly part fields. |

| optWOKitEngChange | T, S, Sy, U | If set to 1 or 2, users will be warned = 1 or prevented = 2 from issuing component parts which have the Engineering-in-Progress set. Operates in WO kitting and backflush and PO Outwork kitting. |

| optWOKitSort | T, S, Sy, U | If set to 1, the sort order of the kit list printed on the Work Order will be by BoM Reference then Part Number rather than just by Part Number. (CalMRP = 4003) |

| optWONewCheckSpec | Sy | Set with any or all of BRQW characters. When a WO is created the system will check that the assembly has a BoM if a B, has a Process Route if an R, has a QA Test Regime if a Q and if a W is entered the user will only be warned rather than prevented. |

| optWONoPartChange | Sy | If set to 1 after you create a Work Order you will not be able to change the order assembly part number. |

| optWOOutworkWarn | T, S, Sy, U | Warn user when receiving Work Orders where outwork operations have not yet been fully received. Normal operation would prevent work order receipt. |

| optWOPickPrintMarkAll | T, S, Sy, U | If set to 1, when printing an WO Picking List it is marked as printed regardless of the report destination. |

| optWOPickSort | T, S, Sy, U | If set to 1, the sort order of the Work Order Picking List will be by BoM Reference then Location then Part Number rather than just by Location and then Part Number. (CalMRP = 4002) |

| optWOPickStoComments | T, S, Sy, U | Set to the number of Stock Location Comments characters that should be printed extra on a Work Order Picking List when multi-locations are shown. |

| optWOPrepDateChange | Sy | If set to 1, WO preparation history will be recorded for completion due date changes. |

| optWOPrintMarkAll | T, S, Sy, U | If set to 1, when printing an WO it is marked as printed regardless of the report destination. |

| optWOProcessListField | T, S, Sy, U | An alternative to WO comments displayed when a line is selected in the part processing quantity drill-down listing. A valid calculation can be entered using fields from the WO and assy Part files. E.G. con(PTMPTNO – PTMDESC) shows part and desc. (CalMRP = 4029) |

| optWOQtySumUoM | Sy | Backflushing WO Receive Qty will be set to the sum of Component quantities with stock UoM equal to text entered here. It is case-insensitive. Good for food or chemicals where the product weight or volume is the sum of kit. (CalMRP = 4004) See also optBoMQtySumUoM. |

| optWOShopDefaultZero | T, S, Sy, U | If set to 1, in Shopfloor Work Operation Data Collection receipt quantity will default to zero rather than the available receipt quantity for the operation. |

| optWOShopOpOutSeq | Sy | If set to 1, users will be permitted to record work order operations out of sequence in Shopfloor Work Operation Data Collection. |

| optWOShopReceive | T, S, Sy, U | If set to 1, users with appropriate privileges and posting final operations in Shopfloor Work Operation Data Collection and Work Tracking will be automatically presented with pre-loaded WO Receipt or Work Order Backflush windows. |

| optWoNoEngChange | T, S, Sy, U | If set to 1, users will be prevented from creating a Work Order for a part which has Engineering-in-Progress set, rather than just being given a warning. |

| optWorkTrackingLateHrs | Sy | This is available to change the time permitted for a finish event to be recorded after which a new Work Tracking record is created. The default is 12 hours unless you enter a numeric value in this option. Decimal hours are permitted. (CalMRP = 4030) |

| optWorkTrackingOpSeq | Sy | If set to 1, users will NOT be permitted to record work order operations out of sequence in Work Tracking. |

| optYesNoStrSwap | Sy | A comma-delimited list of String Numbers for yes/no and no/yes messages that should be reversed from their standard defaults within the program. |

| See also | Settings Maintenance Subwindow |

Compiled in Program Version 6.00. Help date last modified on 9 April 2024

Class woptionslist (Program Options Listing) last modified 25 May 2022 FP: File > System Manager > Calendars