OVERVIEW

This window is used for both the Process — Dispatch — Bond Items function (See Bonding Process below) and the Process — Dispatch — Dispatch Items function.

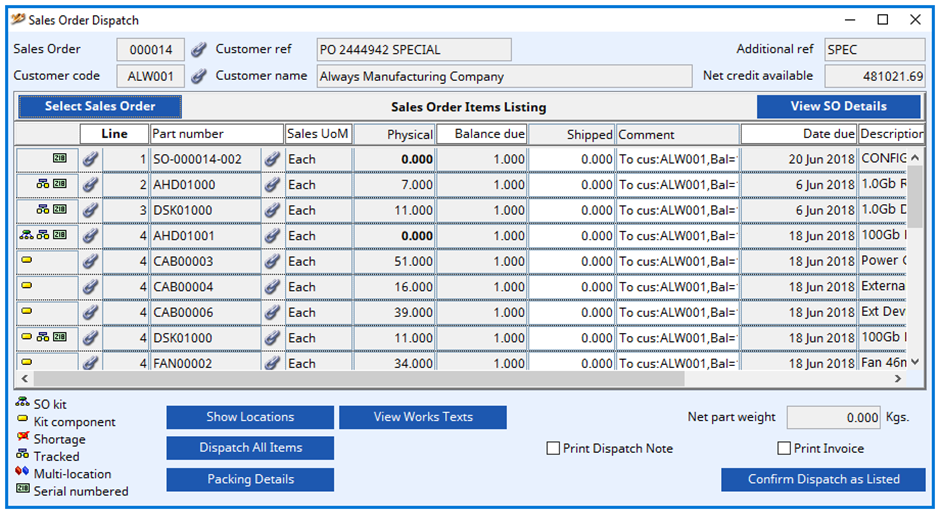

The Dispatch process is called after items have been physically picked from the stockroom. The marked-up Picking List can be used as reference for the confirmation of dispatch. The SO is selected in the Sales Order Selection window. This window then contains a list of all outstanding items for the order regardless of due date.

TIP: You can control whether the Net Available Credit value is displayed on the window using the option optNoShowCredit. You may wish to do this for security reasons as showing the value will enable dispatch staff to calculate the sales price of goods.

Processing of dispatches to customers is done by entering the quantity against each line item that has been shipped. Having prepared the list of dispatches, processing of all the transactions are carried in one operation.

When entering a dispatch, you can enter a non-standard Stock History Comment. In the case of non-stock type parts and non-part items, this option does not apply.

If the customer is marked as Stop if over limit you will not be able to dispatch items that cause the Net Credit Available to go negative.

Part items may have special icons in the list to warn you of special circumstances that will call for pre-processing additional data.

When satisfied that the list accurately reflects the dispatch, click on the Confirm Dispatch as Listed button. A check is then carried out for appropriate serial number and/or multi-location assignments and customer credit authority before any dispatches are processed. If, the Stop if over limit flag is set for the customer and, as a consequence of the dispatch, the customers credit limit is to be exceeded, the processing will be prevented, and you will be warned. To effect a dispatch under these conditions, either the credit limit must be increased or sufficient invoice payments must be made. If the Stop all dispatches flag is set, no dispatches can be made until the flag is reset in the customer maintenance window.

NOTE: If an order is subject to a Cash-Before-Delivery Invoice, there must be sufficient unallocated credit on hand to the customer’s account before a dispatch is permitted, regardless of Stop flags.

Kit shortages: When you do not fully dispatch a Sales Order Item that is a SO Exploded Kit (i.e. where the part is of type P) any quantities of components not dispatched are recorded in the Shortages file. When parts are received into stock this list is checked, and the user notified. The logging of shortages is automatic. The Sales Order is not completed until all shortages have been issues to it.

When you operate the Confirm Dispatch as Listed button, depending on options and the status of dispatched parts, you may be presented with the Serial Number Assignment, Location and Batch Assignment and Trade Statistics Order Details windows. See these topics for details.

When a dispatch is confirmed some or all of the following data processing will take place:

- Shortages for incomplete Exploded Kit components will be created.

- Invoice records are created.

- Sales History, used as Invoice line items, will be created.

- Sales Order Line Item records will be adjusted or deleted if there is no outstanding quantity.

- Sales Order Header records will be deleted if no SO Line Item records remain.

- Part Due to SOs, Period Usage and Physical quantities will be adjusted.

- Multi-Location record Quantities will be adjusted or records deleted if zero.

- Tracking records will be created.

- Product Serial Number records will be related to an assignment.

- Customer On-order and Outstanding invoice values will be adjusted.

- Stock History records will be created.

- Ledger transactions for the Invoice will be created.

- Any relevant General Ledger account balances/turnovers will be updated.

File Path

Process > Dispatch > Dispatch items

This file path takes you to the Sales Order Dispatch window.

Sales Order Number

Sales Order Header. Sales order number (user’s not customer’s). {SOHFILE.SOHSONO char 6}

Link icon

Click to view any linked external files. Hold the shift key down and click to create a new file link for the record.

Customer Ref

Sales Order Header. Customer order reference. {SOHFILE.SOHCREF char 20}

Additional Ref

Sales Order Header. Additional user order entry reference. {SOHFILE.SOHAREF char 6}

Customer Code

Sales Order Header. Customer code. {SOHFILE.SOHCUSC char 6}

Customer Name

Customers. Customer company name. {CUSFILE.CUSCNAM char 40}

Net credit available

Shows the customer credit available after all the dispatches have been completed.

Select Sales Order button

To select a Sales Order from which you wish to make dispatches. It will open the Sales Order Selection window.

View SO Details button

To view the SO Header details that may contain comments relevant to the dispatch. It will open the Sales Order or Quotation Details window.

Dispatch List

A list of all outstanding Sales Order items from the selected order listed above. The following columns are relevant:

SO Line

Sales Order Line Items. Line number. {SOLFILE.SOLLINE number 0dpShortnum}

Part Number

Sales Order Line Items. Part number. {SOLFILE.SOLPTNO char 18}

Sales UoM

Sales Order Line Items. Sales UoM for the item. {SOLFILE.SOLSAUM char 6}

Physical

In item sales units of measure.

Balance due

Sales Order Line Items. Balance quantity due in Sales UoM. {SOLFILE.SOLBAL number 3dp}

Shipped

The quantity being shipped in this dispatch.

Comment

The inventory comment that will be used when recording the part movement.

Date due

Sales Order Line Items. Dispatch date for the quantity. {SOLFILE.SOLDATE date date1980}

Description

Sales Order Line Items. Item description. {SOLFILE.SOLDESC char 32000}

Show Locations button

After placing the cursor in a list line, click to show stock locations with extended information. It will open the Stock Location Listing window.

This button is only available if you have checked the Maintain multi-stock locations extended information in the File — System Manager System Preferences window.

View Works Texts button

After placing the cursor in a list line, click to view details of the Works Text for a selected part. It will open the Part Works Texts window.

Net part weight

Shows the net shipping weight calculated from the part mass values. It takes no account of non-part items.

Dispatch All Items button

Click to set all Dispatch quantities to the full order balance. (This button is only seen during Dispatch)

NOTE: A general option optSODispatchAllNet is available to control the Dispatch All function. If set to 1, the option will cause the dispatch to be loaded with up to the physical quantity available for the order, otherwise the total ordered quantity is set which can cause inadvertent negative stock.

Print Dispatch Note

To print a Dispatch Note when the order is processed. (This checkbox is only seen during Dispatch)

Print Invoice

To print a Invoice when the order is processed. (This checkbox is only seen during Dispatch)

Packing Details button

Click to edit the packing details and weights for this dispatch. This opens the Dispatch or Packing Details window. If you are going to edit the line item weights, you must have first entered the dispatch quantities. (This button is only seen during Dispatch)

Confirm Dispatch as Listed button

Post dispatches when satisfied that all the quantities shown on the list are correct. Dispatch documents and Invoices will be created automatically. (This button is only seen during Dispatch)

If there are any inventory consequences to the process, these will be reported on the Stock Processing Message Log window that will open.

CUSTOM CAPABILITY: oCustom1.$PreDispatchSetup method can be used to integrate pre-dispatch user-assignment of custom data sor that oCustom1.$DespatchMade processing can be carried out within the server transaction. This is important for concurrency control.

| See Also: | Sales Order Selection Serial Number Assignment Location and Batch Assignment Trade Statistics Order Details Sales Order or Quotation Details Part Works Texts |

Compiled in Program Version 6.00. Help date last modified on 13 March 2025

Class wsodispatch (Sales Order Dispatch and Bonding) last modified 25 May 2022 FP: Process > Dispatch > Dispatch items