Bug Fixes

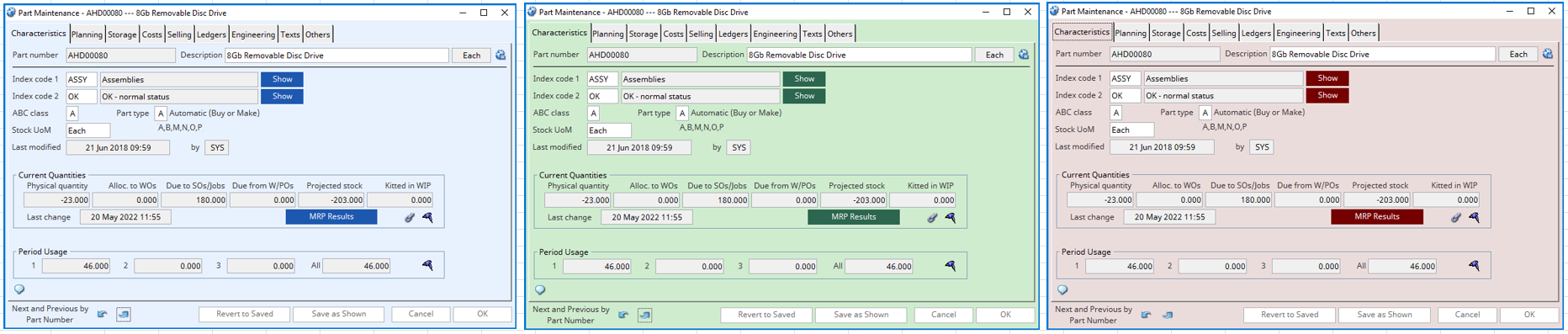

30001 – Multiple windows have had formatting corrected for uniformity

30002 – Repair to incorrect Backflush Error Message

Removal of incorrect error message when receiving a backflush work order where there is also scrap.

30003 – Repair of posting errors in Work Tracking Analysis

30004 – Supplier name now shows correctly on GRN note

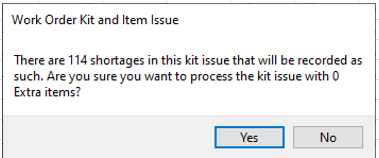

30005 – Fixed Work Order Kit and Item Issue pop up message box.

30006 – Serial numbers can now be changed from standard batch number to a Year-Date-Serial option

30007 – Sales invoice number can no longer allow duplicates

30008 – Cancel button in New Invoice or Credit Note Number window now works

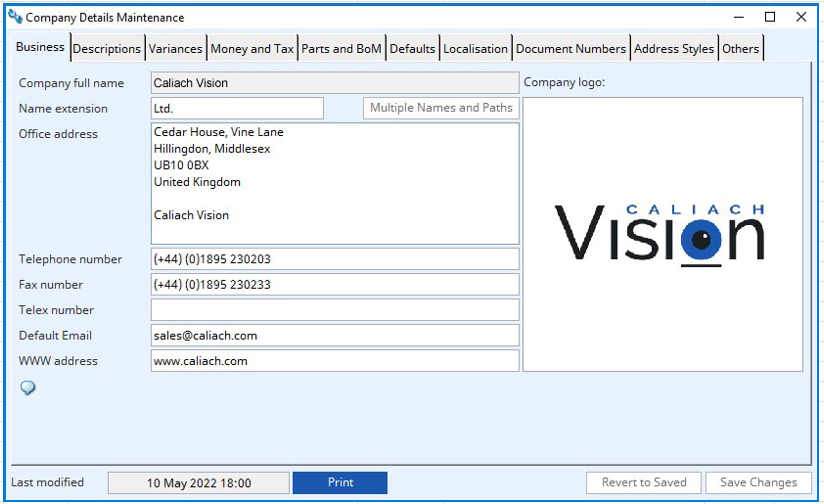

30009 – Company Details Maintenance window bug

Fixed the ability to increment the Sales Invoice number in the Company Details Maintenance window.

30010 – Sales Dispatch Potential Review window data bug

Corrected given information in fields Projected, In Plan and Plan Date in Sales Dispatch Potential Review window

Fixed spacing issues in address fields on Stock Transfer Order report

30011 – Work Order Backflush Window

Glitching in horizontal scrollbar corrected

30012 – Customer Maintenance Window

Fixed address and contact field to automatically fill in the correct customer information in the business tab.

30013 – Resolved issue with graphical glitches.

30014 – General Ledger Journals window

Fixed Copy This Journal button to show as white with grey text when inactive.

30015 – Functionality of buttons repaired in Stock Location Listings window for uniformity within programme.

30016 – Stock Location Listing window, the Part number selection now works as other windows when double clicking, utilising the “Do not Clear Window when Performing a Find” option.

30017 – About Caliach Vision window has been updated with correct information.

30018 – Company Details Maintenance window

Last in First Out (LIFO) method for Materials Costing Method in the Parts and Bom tab is now working correctly.

30019 – Can now record operations when Work Order was set to Backflush

30020 – Fixed MTD after Government API changes.

30021 – Privileges and Settings window

Fixed the locking of tabs so they are greyed out for users without the appropriate Privileges

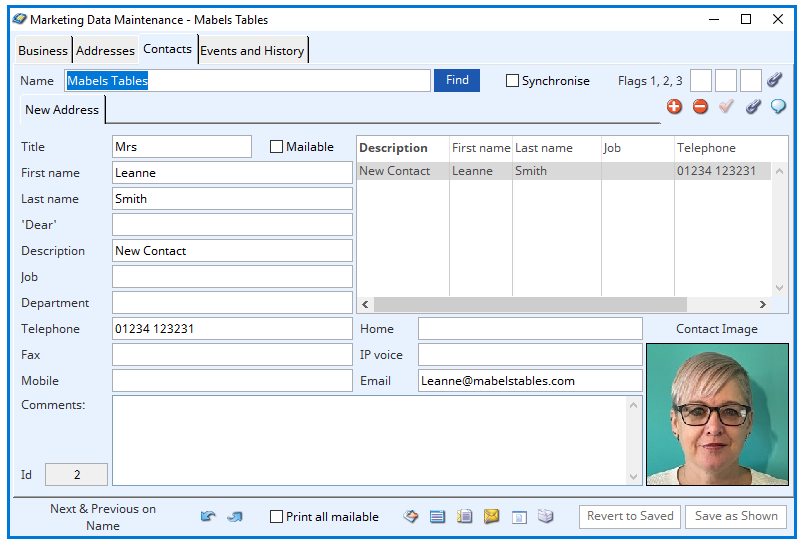

30022 – Fix report from Marketing Data Maintenance window so correct company name shows.

Enhancements

30023– Window Stretch Size

Multiple windows have had minimum stretch size increased to allow users to see whole window

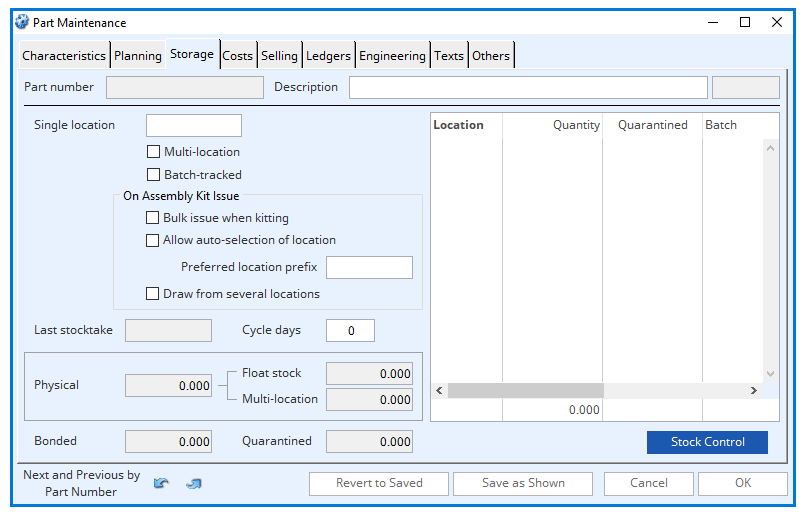

30024 – Parts Maintenance window

All checkboxes in Parts Maintenance window were checkable on the text. They are now only checkable in the square, eliminating options being checked in error.

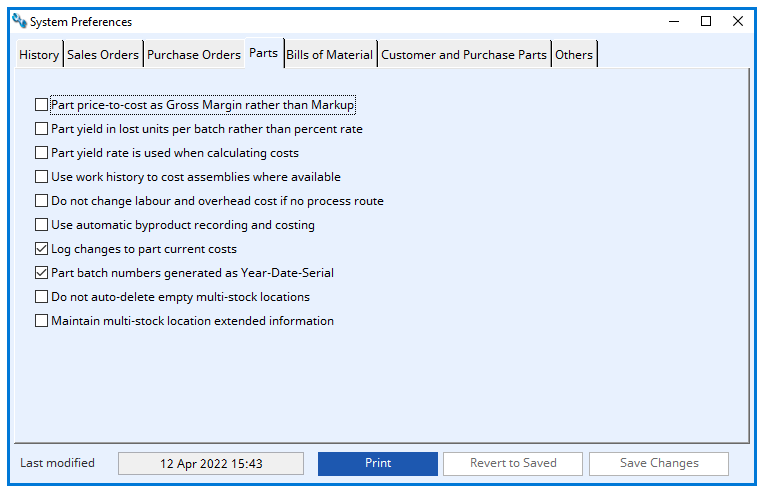

30025 – Parts maintenance – Storage tab

Addition of ‘Stock Control’ button which opens the stock control window. NOTE: This button will only be visible if you have the appropriate privileges.

Addition of ‘Bonded’ field to show quantity of bonded stock.

Addition of ‘Multi-location’ field which ignores quarantined stock.

Changes to layout to allow a better explanation of physical stock

Changed context menu to allow standard options

30026 – Parts maintenance – Engineering tab

Addition of Country of origin, Country list and country title field

Addition of pop-up error message if invalid country code entered

Country of Origin can now be changed with Global changes

30027 – Sales Order Maintenance – Line items tab

Configure New Part button so it is now blue when active

Show button in Mkt. project in Customer and Terms tab is now blue when active

30028 – Work History Listing improvements

Addition of fields ‘Run time’, ‘Setup time’, Trans ID’, ‘Scrap Code’.

Upon double clicking a selected line, the ‘Log Work Order Operational Performance’ window will open with the line pre-selected.

30029 – Log Work Order Operational Performance Window Improvements

Addition of ‘Trans ID’ column.

The window is now correctly formatted for uniformity and minimum stretch size increased.

30030 – Work Order Backflush window

Planned Completion tick box in Work Order Backflush window has been changed to only allow selection if box is checked

Icons now showing in Explode Parent grid

30031 – Time fields are now visible in Work Tracking Labour Rate Schedule window

30032 – Work Tracking Analysis window

New fields added – Received, Scrapped, Scrap code, Scrap Reason, Trans ID and Part number

Corrected button colour of Delete Selected button from blue to red

30033 – Received Work Order Assemblies from Production window

Updated to allow partially kitted work order to be united if all permitted have been received but there is still a balance remaining.

30034 – Work Order Kit and Item Issue window improvements

Added ‘List Kit Changes’ checkbox, if checked, this will print out a detailed changes report

Added ‘Pass results to Receive WO Assy window’ check box. If selected, once a quantity is processed, it will pass directly to the Receive Work Order window with the maximum receivable quantity pre entered.

30035 – Work Operation Tracking window improvements

Added Remaining Qty box

Added fields Hr:Mins, Part Number, Trans ID, Received, Scrapped, Scrap Code, Scrap Reason.

Record Quantities check box in Work Operation Tracking window can now only be checked if the box is selected.

New option added to allow operations to be recorded for an unkitted works order (in option settings)

New option to auto post time and labour cost direct to Works order history. Allows you to accumulate all times for previously posted operation times (in option settings)

Now records operations when Work Order is set to backflush

Repaired the ability to up the quantity of a work order if all operations have been posted but the work order has not yet been received to allow the posting of the extra quantities in the Shopfloor Work Operation Data Collection window.

30036 – Delete posted op button added to Shopfloor Work Operation Data Collection window.

30037 – Removed invoice number limitation

Invoice number field in Company Details Maintenance window is not limited to six figures to avoid duplicate invoice numbers

30038 – EORI number now automatically entered on Stock Transfer Order

30039 – Add images in Marketing Data Maintenance window

Ability to enter any size image into the Contact Image box in Marketing Data Maintenance window.

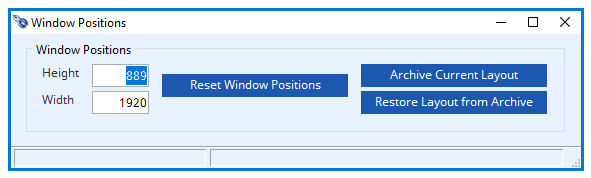

30040 – Reset Window position and Size

Reintroduction of ability to allow user to reset the window positions and size.

30041 – Work Tracking Analysis window

Double clicking a line in the Order column now opens the ‘Log Work Order Operational Performance’ window with the line pre-selected.

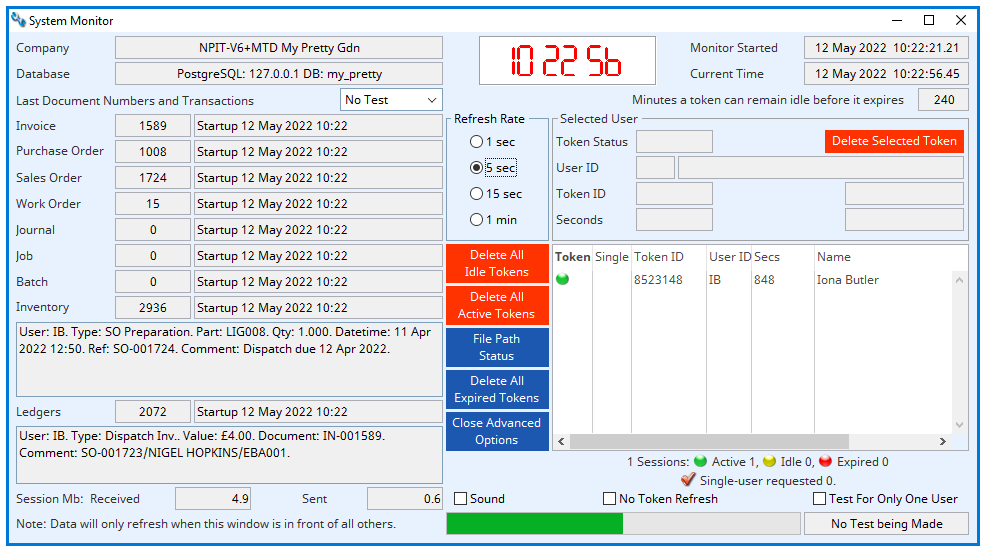

30042 – System Monitor window

Addition of Selected User field to allow the selected users data to be displayed including token time to idle and token time to expiry.

New function added to allow any expired tokens to be automatically removed when any user logs on to Caliach.

Delete All Expired Tokens button has been added to the System Monitor window.

Advanced options button has been added to the System Monitor window. This is protected and will require an admin User ID and Password.

When the Advanced options button has been selected, the ‘View User Session log’ and ‘File Path Status’ buttons become ‘Delete All Idle Tokens’ and ‘Delete All Active Tokens’ buttons and a Delete Selected Token button appears. These all become red.

Old clock has been updated with a digital clock in System Monitor window.

Minutes a token can remain idle before it expires file has been added. The default for this is 240 minutes.

Token expiry due field added.

Sessions Active, Idle and Expired count added.

Single user requested icon changed to a tick.

Ability to view the pre-selected user sessions in the User Login Sessions window by selecting the View User Session Log button.

30043 – Work Order Maintenance window

List Kit on Printed WO when creating a new works order can be set to unchecked by default.

30044 – General Ledgers Journal

Changed Print button to Print Journals for clarity.

Added Totals – to Debit and Credit fields.

30045 – Bills of Material Maintenance window

Addition of the below buttons. Previously these processes could only be reached via context menus:

Addition of Bom List icon button

Addition of Select Parent button

Addition of Change Parent Type button

Addition of Expand All icon button

Addition of Update Parent Costs button

Addition of Edit Component button

Addition of Add Component button

Addition of Delete Component button

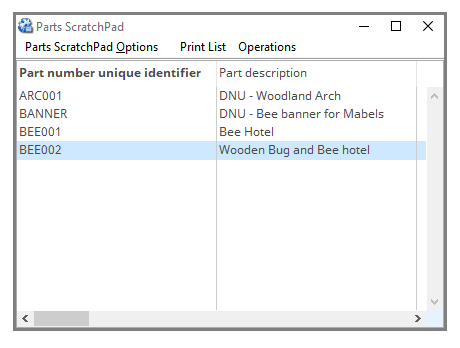

Addition of Add parts to Scratchpad Icon button

Addition of BoM list to the Tree context menu

Ability to enable Bills of Materials fast view mode as default via checkbox

Addition of Auto-Add to Scratchpad checkbox

30046 – Character count in Description field in part Maintenance window has been increased to 40 characters.

30047 – Country of Origin can no longer be left blank in the Engineering tab in the Part Maintenance window.

30048 – Company Details Maintenance window

New costing methods (Static date and Rolling period) have been added to the Average of History for Materials Costing Method in the Parts and Bom tab.

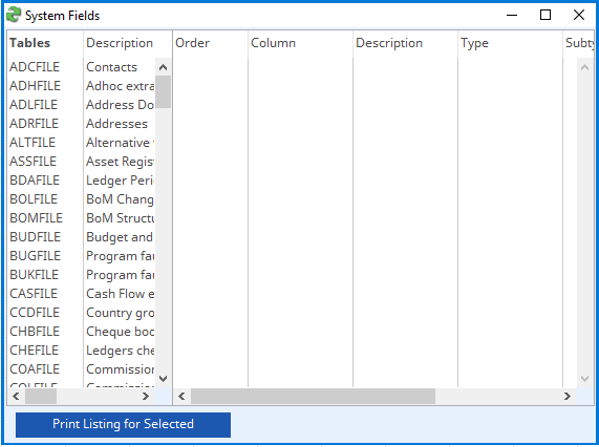

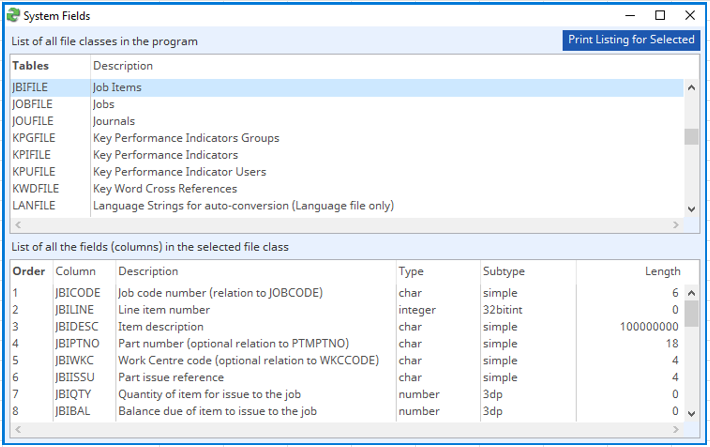

30049 – Added System Fields to the help menu for ease of access.

30050 – System Fields window rearranged to show maximum information.

Old Style window

New Style window

30051 – Ability to ‘unlock’ a Job or Estimate, if it is open with another user, from the Select Job or Estimate window.

30052 – Ability to ‘unlock’ an Order or RFQ, if it is open with another user, from the Select Order or RFQ window.

30053 – Ability to ‘unlock’ an Order or Quote, if it is open with another user, from the Select Order or Quote window.

30054 – Ability to ‘unlock’ a Work Order, if it is open with another user, from the Select a Work Order window.

30055 – User Settings Maintenance window

Addition of fields in the ScratchPads tab to allow the full description of a selected line to be displayed and the headings be re-named.

30056- Stock Control Activities window

Addition of part type field

Addition of Multi-Location field

Addition of Primary Supplier field

Addition of Lot size

Addition of Minimum order qty field

Addition of Bonded field

Addition of Part Maintenance button

30057– Company Details Maintenance window

New Database Type field added to show which type of database you are in and gives you the option to change them.

30058 – Create New Database and Copy Data window

New Advanced Features checkbox

New Create/Renew Play Data button added

Change Settings button updated to Change Database Connection Settings

Target database no longer defaults to your main database

Server username and server password fields will appear if no password and Username added for DBMS

New Copy to Target Database field added

New Delete/Drop Target Database button – Note: you cannot delete Master databases

Several Yes/No/OK warning messages added to prevent accidental loss of data

New colours for each database type added

Master Database-locked Play Database-unlocked Copy Database-unlocked

New Features

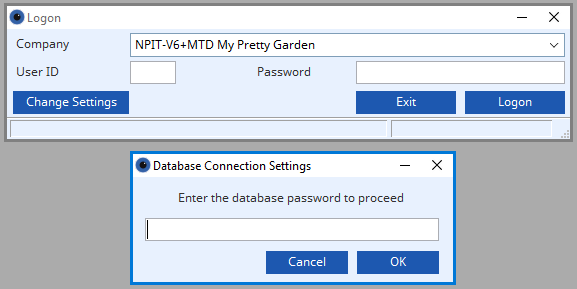

30059 – Change Settings button in Login window is now password protected

To eliminate the chance of the connection settings being deleted in error. After entering a password, upon selecting the Delete button, a warning box will pop up asking you to confirm your action.

30060 – New options added in Privileges and Settings window

Removal of ‘Work Order Kit and Item Issue’ shortage notice for every short part and replaced with single warning message containing quantity of short parts

Ability to open Receive WO Assemblies window with maximum permitted quantity pre-entered from Works Order Kit and Item Issue window

New section available in Work Order Kitting Window to allow the user to clear either the requirement of parts in the kit list or to issue any quantity for parts that have had their requirement cleared.

Ability to automatically post the Set & Runtimes and the Overhead and Labour costs to the Work Order History window from the Work Order Tracking window.

Option to set accumulation mode for Work Order History.

Option to make a Delete Posted Op button available on Shopfloor Work Operation Data Collection window.

Option to determine the default state of the Record Quantities checkbox in the Work Operation Tracking window.

Ability for user to be permitted to record work order operations in Shopfloor Data if the work order is un-kitted.

Option to automatically un-kit and clear any shortages after receiving WO assemblies if all permitted are received but there is an outstanding balance.

Option to supress any Sales Order uncommitted stock warning message when adding lines to a Sales Order

Ability to have the ‘List Kit on Printed WO’ checkbox unchecked when creating new Works Orders as standard.

30061 – Maintenance window

New icon on all tabs: ![]() Clicking this icon will open the parts scratchpad with the part pre-selected.

Clicking this icon will open the parts scratchpad with the part pre-selected.

30062 – Parts Global Changes window

Addition of Country of Origin to Changes To Be Made tab

30063 – Inventory History Report Selection window

New field added to allow searches and reports by user.

30064 – Company logo can now be added in the Business tab in the Company Details Maintenance window.