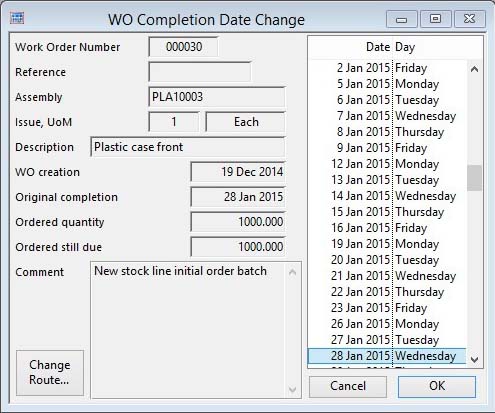

WO Completion Date Change

This window enables you to review a Work Order and re-schedule its completion date by selecting a new date in the list. The window opens when you double-click on a Work Order in the Work Centre Make-To List or in the Work Orders window which is opened by double-clicking on a load line in the Work Centre Loading Chart window.

Using the list on the right of the window you can select a new completion date. If you then confirm with an OK all Capacity Planning lists are re-calculated to reflect the new completion date.

|

Field |

Description |

|---|---|

|

Work Order Number |

Work Orders. Work order number. {WKOFILE.WKOWONO char 6} |

|

Reference |

Work Orders. User reference for WO. {WKOFILE.WKOUSER char 15} |

|

Assembly part number |

Work Orders. Part number (parent assembly). {WKOFILE.WKOPTNO char 18} |

|

Issue |

Work Orders. Assembly part issue reference (when WO created). {WKOFILE.WKOISSU char 4} |

|

Unit of Measure |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

WO creation date |

Work Orders. Ordered date. {WKOFILE.WKOODAT date date1980} |

|

Original completion date |

Work Orders. Date of planned completion. {WKOFILE.WKOCDAT date date1980} |

|

Ordered quantity |

Work Orders. Quantity ordered. {WKOFILE.WKOOQTY number 3dp} |

|

Ordered still due |

Work Orders. Balance due still for completion. {WKOFILE.WKOBAL number 3dp} |

|

Comment |

Work Orders. Comments printed on header of WO. {WKOFILE.WKOCOMM char 2000} |

|

New completion date list |

Make calendar. Select a date that will become the new WO completion date. It can not be earlier than the current active day. |

|

Button |

Action |

|---|---|

|

Change Route… |

Click to amend the route operations that will apply to the Work Order. Any changes will effect operation loading listings, when confirmed. This button control opens the Work Order Operation List Maintenance window to permit changes to the operational route for the single selected WO. After amendment, if the Apply To WO button is not clicked, the selected WO will have the assembly’s standard route of operations.

There are some rules and restrictions that apply:

|

|

Cancel |

Aborts the process currently in session. The keyboard equivalent is the Esc key for Windows computers and Command-.(full stop or period) for the Mac. |

|

OK |

The OK button updates the data you have entered, or confirms the selection and/or processes the function you have called. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:47:00.00. Class wCplWoDateCh last modified 23 Sep 2017 10:50:49.