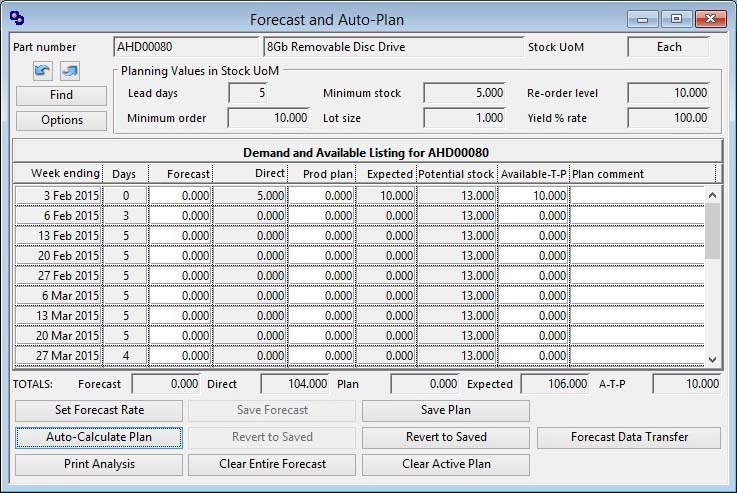

Forecast and Auto-Plan

The Forecast and Auto-Plan can be set to a variety of time buckets. When you operate this function from Process — Material Planning — Forecast and Auto-Plan, you are first presented with a Forecast Period Selection window. You can also reset the options by clicking on the Options button.

In the case of weekly buckets the system takes the last active weekday of each week in the appropriate calendar as the forecast date. In the case of monthly buckets the system takes the last active day of each month in the appropriate calendar as the forecast date. This means that weekly and monthly buckets are not necessarily of equal number of days. If there is only one active calendar day in a particular week, a bucket for that week will be shown. The number of active days in each bucket is shown on the list.

You can choose the Use Sales UoM rather than Stock UoM option in cases where there is a complex conversion which would otherwise lead to odd numbers.

![]() WARNING: MRP will take any resulting Production Plan as a specific requirement to dispatch goods on the plan dates. Therefore, if you forecast and plan by weekly or monthly buckets you should take care that you forecast demand in advance of expected dispatch so that production will be suitably ahead of the expected need to dispatch. For example, say you expect to ship 100 units during the month of June. If you use monthly buckets there will be only one list line dated Jun 30. If you enter 100 on this line, MRP will schedule production to be completed by 30th June and therefore none of the expected demand can be satisfied until the end of the month. What you should do in this circumstance is forecast the demand in the May 31 line, the production will be completed by the beginning of June making it available for dispatch from stock throughout the month.

WARNING: MRP will take any resulting Production Plan as a specific requirement to dispatch goods on the plan dates. Therefore, if you forecast and plan by weekly or monthly buckets you should take care that you forecast demand in advance of expected dispatch so that production will be suitably ahead of the expected need to dispatch. For example, say you expect to ship 100 units during the month of June. If you use monthly buckets there will be only one list line dated Jun 30. If you enter 100 on this line, MRP will schedule production to be completed by 30th June and therefore none of the expected demand can be satisfied until the end of the month. What you should do in this circumstance is forecast the demand in the May 31 line, the production will be completed by the beginning of June making it available for dispatch from stock throughout the month.

Planning Alias

If you have chosen the Combine any parts that Alias to the selected part option in the Forecast Period Selection window, and if the part is referenced by any other part as a Planning Alias, the system will include the unsatisfied demand that all such parts could make on the selected part.

One use of a Planning Alias is to use it to identify a part’s membership of a production group of like parts. You can set up a part that is a typical member of this product group. All of the specific products are then given the typical part as a Planning Alias. If you then Forecast on this typical part, you will be able to view a Forecast and Production Plan of the family of specific products with respect to the demand in sales orders for all of them.

If you Forecast and Plan on an Alias, run MRP to include Production Plan items and Sales Orders, and then have your sales staff view “Part Available-to-Sell…” reviews, you will, in effect, be planning and selling from a product family production schedule.

![]() TIP: This operates effectively only if you routinely generate a production plan from all Alias forecasts before running MRP. You must also process MRP with both demand for Sales Orders and Active Production Plan items set.

TIP: This operates effectively only if you routinely generate a production plan from all Alias forecasts before running MRP. You must also process MRP with both demand for Sales Orders and Active Production Plan items set.

Forecasting

Historic forecast items are automatically deleted from file at the time the list is prepared.

Any existing sales Forecast, Sales Orders, Jobs and active production plan items are combined into the list presented. The current physical stock is projected forward to show the consequences of the forecast. The Available-To-Promise column is calculated from the foregoing and represents the uncommitted quantity that is available to assign to customers from the dates against which they are shown.

![]() NOTE: Available-To-Promise nets the predicted stock assuming that the direct demand is satisfied and the Plan quantity is available to dispatch on the dates shown.

NOTE: Available-To-Promise nets the predicted stock assuming that the direct demand is satisfied and the Plan quantity is available to dispatch on the dates shown.

Projected stock reflects outgoing quantities from direct demand or forecast, whichever is the greater. A-T-P reflects direct demand only, and represents the commitments that can be made if the plan transpires into reality.

![]() WARNING: You must not think of Production Plan items as the quantity of parts that will be manufactured in production. There is no direct relationship to Production Plan quantities and the manufacturing recommendations of MRP. MRP will view, if the option is chosen, Production Plan quantities as direct demand similar to Sales Orders and will use normal algorithms to assess the need to manufacture the part and in what quantity and on which date.

WARNING: You must not think of Production Plan items as the quantity of parts that will be manufactured in production. There is no direct relationship to Production Plan quantities and the manufacturing recommendations of MRP. MRP will view, if the option is chosen, Production Plan quantities as direct demand similar to Sales Orders and will use normal algorithms to assess the need to manufacture the part and in what quantity and on which date.

![]() NOTE: This process has no effect on Inactive production plan items. However, when you save the listed plan, all currently active items are replaced with the saved listed plan.

NOTE: This process has no effect on Inactive production plan items. However, when you save the listed plan, all currently active items are replaced with the saved listed plan.

![]() WARNING: The program gives you the freedom to select the driving demand in MRP processing. However, an auto-calculated plan assumes that the plan is the ONLY demand on production for the part. In other words, if you use this forecasting feature to generate a plan, you should only save Production Plan items when you want them to be added to any Sales Orders. In this case you should set both Sales Orders and Production Plan items as demand options for MRP processing.

WARNING: The program gives you the freedom to select the driving demand in MRP processing. However, an auto-calculated plan assumes that the plan is the ONLY demand on production for the part. In other words, if you use this forecasting feature to generate a plan, you should only save Production Plan items when you want them to be added to any Sales Orders. In this case you should set both Sales Orders and Production Plan items as demand options for MRP processing.

![]() WARNING: When you use the this window any customer forecasts will be combined with others for a part. If the forecast is then saved the customer-specific information is lost and that element of the forecast will not be then visible in the Customer Sales Forecast window.

WARNING: When you use the this window any customer forecasts will be combined with others for a part. If the forecast is then saved the customer-specific information is lost and that element of the forecast will not be then visible in the Customer Sales Forecast window.

|

Field |

Description |

|---|---|

|

Part number |

Parts Master. Part number unique identifier. {PTMFILE.PTMPTNO char 18} |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Stock UoM |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Lead days |

Parts Master. Lead time in active (buy or make) days. {PTMFILE.PTMLEAD number 0dpShortnum} |

|

Minimum stock |

Parts Master. Minimum stock level. {PTMFILE.PTMMINS number 3dp} |

|

Re-order level |

Parts Master. Re-Order level. {PTMFILE.PTMROLE number 3dp} |

|

Minimum order |

Parts Master. Re-order quantity. {PTMFILE.PTMREQT number 3dp} |

|

Lot size |

Parts Master. Lot size when ordered. {PTMFILE.PTMLOT number 3dp} |

|

Yield |

Parts Master. Yield percent (default 100.00). If system preference MCDYIEU set Yield unit loss (default 0.00). {PTMFILE.PTMYIEL number 2dpShortnum} |

|

Demand and Available List |

A listing that covers the extent of the system calendar showing the projected inventory conditions. Make changes within the grid. |

|

Total Forecast |

The total quantity of forecast demand. |

|

Total Direct |

The total direct demand. In this analysis direct demand does not include production plan quantities. |

|

Total Plan |

The total planned quantity of the production plan listed. |

|

Total Expected |

The total quantity that is expected to be ordered on production as a consequence of the next MRP run. |

|

Total ATP |

The total quantity that is currently Available-to-Promise. A-t-P ignores the forecast but does not consume stock below minimum. |

|

Button |

Action |

|---|---|

|

Find |

To locate a new part for forecasting. It opens the Part Selection window. |

|

Options |

To change the forecasting options. It opens the Forecast Period Selection window. |

|

Set Forecast Rate |

To assign a forecast demand value for each of the days or weeks listed. You will be prompted for a value. |

|

Auto-Calculate Plan |

To have the system calculate an appropriate production plan for the parameters you have entered in the list. |

|

Print Analysis |

To obtain a printed report of the list details. |

|

Save Forecast |

When available, this will save the forecast as shown on the list for future use. |

|

Revert to Saved Forecast |

When available, this will revert the forecast values to those last saved. |

|

Clear Entire Forecast |

To delete all forecast values from the list and file for this part. |

|

Save Plan |

When available, to save the production plan that is currently listed on the window. This plan can then be used by MRP processing. |

|

Revert to Saved Plan |

When available, to revert to the active production plan saved on file. |

|

Clear Active Plan |

To delete the entire active production plan from the list and all active plan items from the file. |

|

Forecast Data Transfer |

To import or export a forecast data set. It opens the Forecast Data Transfer Options window. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:48:00.00. Class wMpsFore last modified 4 Aug 2015 10:34:43.