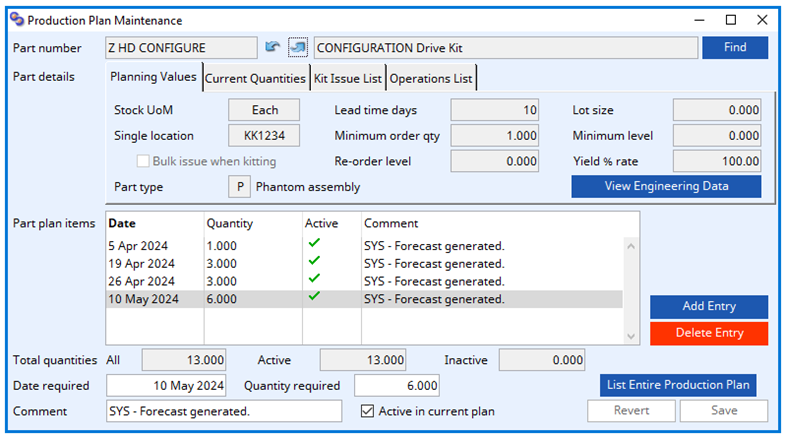

OVERVIEW

The Production Plan is a list of parts that you plan to sell, or otherwise need, in addition to other demand placed on MRP such as Sales Orders or Quotations. Production Plan quantities are, in effect, artificial Sales Orders.

WARNING: You MUST NOT think of Production Plan items as the quantity of parts that will be manufactured in production. There is no direct relationship to Production Plan quantities and the manufacturing recommendations of MRP. MRP will view, if the option is chosen, Production Plan quantities as direct demand like Sales Orders and will use normal algorithms to assess the need to manufacture the part and in what quantity and on which date.

TIP: Setting a Production Plan for a part is useful where you do not have a Sales Order lead time sufficiently long for proper scheduling of lower level items. You can use the plan to artificially load direct demand on MRP for the future, when it is unlikely that Sales Orders will cover a realistic level of factory output.

TIP: There is a very useful system preference which can automatically adjust the production plan to take account of dispatches. For details see the System Preferences window Sales Orders tab pane.

File Path

Process > Material Planning > Production & Planning…

This file path takes you to the Production Plan Maintenance window.

Part Number

Parts Master. Part number unique identifier. {PTMFILE.PTMPTNO char 18}

Down and Up arrows

Click to find the preceding or next value of the field alongside. By repeatedly clicking you can cycle through the file. After the files last record an audible tone will sound and the first record on file will be found.

Part Description

Parts Master. Part description. {PTMFILE.PTMDESC char 30}

Part Details

For details of this tab pane see the Assembly Details subwindow.

Find button

To locate a new part for production plan review or maintenance.

Part plan item list

Lists all plan items for the selected part. Click on an item to select and edit below.

Add Entry button

To add a new plan item.

Delete Entry button

To delete the selected production plan item.

Total quantities all

The total quantity for all plan entries, both active and inactive.

Total active

The total quantity for active entries only.

Total inactive

The total quantity for inactive entries only.

Date required

Planned completion date. {PRDFILE.PRDDATE date date1980}

Quantity required

Quantity due on date. {PRDFILE.PRDQTY number 3dp}

List Entire Production Plan button

To open a window with a list of all production plan items of all parts. This will open the Production Plan Full Listing window.

Comment

Comments. {PRDFILE.PRDCOMM char 30}

Active in current plan

Active flag. {PRDFILE.PRDACTV boolean

Revert button

To revert any changes to the previously saved version.

Save button

To save the changes you have made to the data file.

Compiled in Program Version 6.00. Help date last modified on 11 July 2024.

Class wprdentry (Production Plan Maintenance) last modified 25 May 2022 FP: Process > Material planning > Production & Plan…