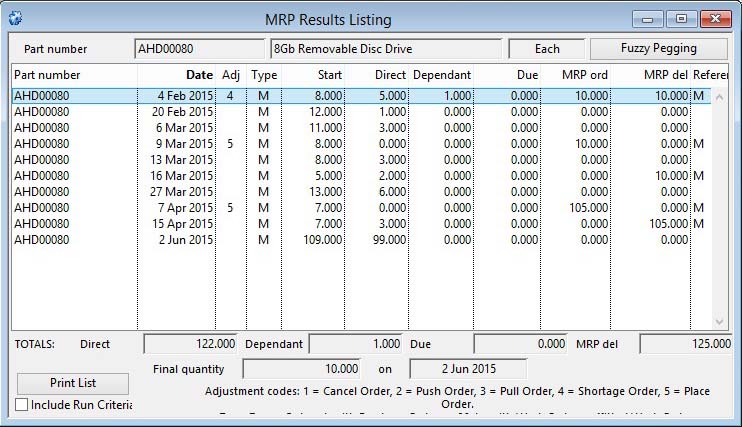

MRP Results Listing

See later for a full discussion on MRP Results. See the MRP Menu topic for a discussion on how MRP works.

|

Field |

Description |

|---|---|

|

Part number |

Parts Master. Part number unique identifier. {PTMFILE.PTMPTNO char 18} |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Stock UoM |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

List |

The list provides the entire MRP results for the part. Double-click to drill down to the selected order. |

|

Total direct |

The total direct demand listed. |

|

Total dependant |

The total dependant demand listed. |

|

Total due |

The total due from current amended orders. |

|

Total MRP orders |

The total recommended MRP order deliveries. |

|

Final quantity |

The predicted final quantity in stock for the part. |

|

Final Date |

The last date in the plan for this part. |

|

Include Run Criteria |

Check this option if you want the report to contain a listing of the MRP run criteria that produced the results. |

|

Button |

Action |

|---|---|

|

Fuzzy Pegging |

Will provide a demand list of assemblies that may be contributing to dependant demand for the selected part. It opens the MRP Fuzzy Pegging Analysis window. |

|

Print List |

To print a report of the listed items. |

MRP Results

The MRP Run produces the MRP Results file which contains the following data:

|

Field |

Description |

|---|---|

|

Part number |

Part Number of the component or assembly for which a forecast action or demand has been identified by MRP.

|

|

Action date |

The date on which there is direct demand, from one of the selected criteria, dependant demand, from the Bill of Materials requirements to manufacture the demand items to the lowest level, receipt from a current Purchase or Works Order, recommended change in timing of orders or MRP recommendations for orders and their delivery. |

|

Part supply type |

B = Buy component where recommended orders are Purchase Orders.

|

|

Adjustment code |

This is an action identifier that has the following meaning: 0 = No change to order, simply a prediction of inventory movement. 1 = Cancel Purchase or Work Order. Cancellation is recommended if future projected stock quantity does not fall below Re-order Level. The recommended quantity to cancel is shown as a negative MRP Order quantity and the balance to leave on order will show in the Order delivery quantity. 2 = Push Purchase or Work Order to a later receipt date. A Push recommendation is made if the order delivery can be delayed, without the projected stock quantity falling below Minimum Stock, beyond a date after the threshold days have been added to the current delivery date. 3 = Pull Purchase or Work Order for earlier receipt. A Pull recommendation is made if the order delivery is needed earlier than the current delivery date, due to the projected stock potentially falling below Minimum Stock. 4 = Shortage order recommendation. This is an MRP suggested order where there is less available calendar days than the part’s lead time between ordering and need for delivery. 5 = MRP recommended Purchase or Work Order. This is a normal MRP suggested order where the normal part lead time is available. MRP recommended order quantities are either the Order Quantity for the part or such greater quantity that will leave the projected quantity at the Re-order Level. |

|

Start quantity |

The predicted physical stock at the start of the Action Date.

|

|

Dependant demand |

Consumption quantity predicted due to dependant requirement to the lowest level (i.e. demand from a Bill of Material) for direct demand items. |

|

Order delivery quantity |

Delivery quantity from already prepared Purchase or Work Orders, if MRP recommends cancellation this value may be zero. |

|

MRP Order quantity |

MRP proposed order quantity. For cancelled orders, the quantity recommended to be cancelled from the order is shown as a negative value. |

|

MRP Order delivery |

Quantity of receipt from an MRP proposed order. This should always be the number of lead days ahead of the MRP Order quantity for normal order recommendations but will be less for shortage orders. |

|

Reference |

This field is automatically filled under the following circumstances: |

|

Implemented |

This flag (Yes/No) field is automatically set when Purchase or Work Orders are generated from the recommendations in one of the “MRP Results” functions. Once they have been marked as implemented, further listings of PO or WO recommendations will exclude them. This avoids duplications of orders. |

Interpretation of results

Although there are many selective ways to view MRP Results data, full interpretation is only possible when all results for a particular part are shown together and sorted correctly.

On the report, a line of part information precedes the results. This information includes all critical planning parameters that MRP uses.

![]() WARNING: Part parameters are those at the time of printing the report or review and may have changed since MRP was run.

WARNING: Part parameters are those at the time of printing the report or review and may have changed since MRP was run.

BOMK Start Dir Dep't Order MRP MRP

Date Adj qty dmd dmd Deliv Order deliv. Reference

------------------------------------------------------------------

NOV 15,1993 K 3 6 4 0 2 0 0 W000001

NOV 15,1993 M 4 4 0 0 0 6 6 M

NOV 17,1993 M 5 10 3 0 0 4 0 M

NOV 19,1993 M 7 0 0 0 0 4 M

On reports without restrictions on records for a part, there will also be a total line that shows:

Final planned = 11.000 Surplus = 1.000

For the example shown above:

On the Nov. 15th there is a dispatch (direct demand) due of 4 from a stock of 6. This however causes the stock to drop below the minimum stock of 5. As there is a kitted Work Order for 2 due for delivery, but at a later date, this is pulled (Adjustment 3) to boost the resultant stock to 4. However, this is still less than the minimum stock. On the same day, therefore, a shortage order (Adjustment 4) is recommended to make 6 for delivery on the same day. This will return the stock to the Re-order Level of 10.

On the 17th there is a further dispatch due for 3, which drops the stock below re-order level. MRP therefore recommends an order (Adjustment 5) for 4 with a delivery 2 working days (lead time) later on the 19th. The order is for 4 because the minimum order quantity is 4, otherwise it should have been 3. The final stock is therefore 11, which is a surplus of 1 over the re-order level.

In the above example there was more demand than stock and supply. Where supply is greater than demand other recommendations will be made.

In this example the physical stock when MRP was run was 13.000.

BOMK Start Dir Dep't Order MRP MRP

Date Adj qty dmd dmd Deliv Order deliv. Reference

------------------------------------------------------------------

NOV 17,1993 M 1 13 0 0 0 -4 0 W000006

NOV 18,1993 M 0 13 2 0 0 0 0

NOV 20,1993 M 2 11 6 0 5 0 0 W000008

Final planned = 10.000 Surplus = 0.000

In this case there is now no need for Work Order W000006 as stock is well in excess of re-order level. MRP therefore recommends that the order is cancelled (Adjustment 1) in full. All the order quantity of 4 are cancelled, indicated by a -4 in the MRP order column and 0 remaining on order in the Order delivery column. There is then a dispatch due on Nov. 20th which only reduces stock to 11, still above re-order level.

On Nov. 28th there is a further dispatch which would drop the stock below Re-order level. Prior to that there was a completion due from Work Order 000008 which does not need to be completed before the 28th. MRP therefore recommends that the order is pushed (Adjustment 2) to the 28th, when it is needed to ensure the stock ends at the re-order level.

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:48:00.00. Class wMrpList last modified 23 Sep 2017 10:50:58.