MRP Fuzzy Pegging Analysis

After selecting a part in the MRP Results Listing window, clicking on the Fuzzy Pegging button will open this window.

Fuzzy Pegging is a sort of MRP demand pegging. In conventional pegging the system records the source of all dependant demand for a part through multiple levels. This is an enormously intensive process to add to the MRP processing and would consume considerable database space. As an alternative, Fuzzy Pegging is a presumptive analysis of the demand items that are currently on the system that could be contributing to the demand on the part.

The system carries out a multi-level where used analysis on the selected part and identifies any demand for parent items in the where-used list.

The list interactively operates with the Parts ScratchPad and the Bill of Materials and Where-Used Listings window that can be opened from the Parts ScratchPad Options Menu menu. This window will interactively operate with the Results Listing window. I.E. If you click on a BoM listed part the system will attempt to list the MRP results for that part.

|

Field |

Description |

|---|---|

|

Part number |

Parts Master. Part number unique identifier. {PTMFILE.PTMPTNO char 18} |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Stock UoM |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Demand List |

The list provides potential demand that has loaded the part. Double-click to drill down to view and order. |

|

Total quantity |

The total demand quantity. |

|

Include Work Orders with Ignore in MRP |

With this flag set, WOs that have had the Ignore in MRP option set are included as sources of dependant demand. |

|

Button |

Action |

|---|---|

|

Print List |

To print a report of the listed items. |

The window has 3 tab panes.

Planning Values

Current Quantities

Period Usage

Planning Values

Planning details for the assembly.

|

Field |

Description |

|---|---|

|

Stock UoM |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Lead time |

Parts Master. Lead time in active (buy or make) days. {PTMFILE.PTMLEAD number 0dpShortnum} |

|

Lot size |

Parts Master. Re-order quantity. {PTMFILE.PTMREQT number 3dp} |

|

Single or Preferred Location |

Parts Master. Stores single or preferred location. {PTMFILE.PTMSLOC char 8} |

|

Minimum Order Quantity |

Parts Master. Re-order quantity. {PTMFILE.PTMREQT number 3dp} |

|

Minimum Stock |

Parts Master. Minimum stock level. {PTMFILE.PTMMINS number 3dp} |

|

Bulk issue when kitting |

Parts Master. Bulk issue flag. {PTMFILE.PTMBULK boolean} |

|

Re-order Level |

Parts Master. Re-Order level. {PTMFILE.PTMROLE number 3dp} |

|

Yield |

Parts Master. Yield percent (default 100.00). If system preference MCDYIEU set Yield unit loss (default 0.00). {PTMFILE.PTMYIEL number 2dpShortnum} |

|

Part Type |

Parts Master. Part type (A,B,M,N,O,P). {PTMFILE.PTMTYPE char 1} |

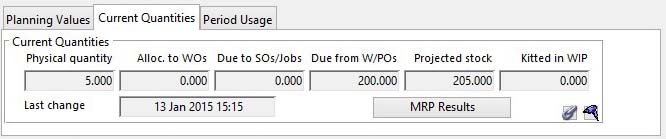

Current Quantities

Current quantities for the assembly. For details see the Parts Current Quantity subwindow.

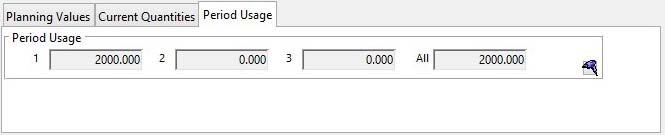

Period Usage

Period usage for the part. For details see the Parts Usage subwindow.

| See also: – |

Compiled in Program Version 5.10. Help data last modified 8 May 2012 06:20:00.00. Class wMrpPegging last modified 23 Sep 2017 10:50:58.