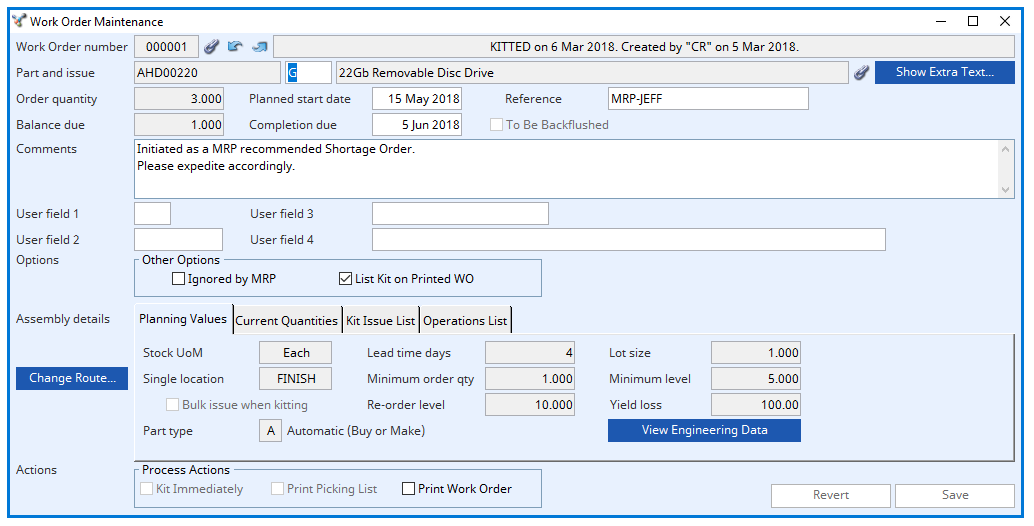

OVERVIEW

This Maintenance window opens from the Work Orders Menu. See this topic for a general introduction to Work Orders and the processing of them.

File Path

Process > Work Orders > Select a Work Order…

This file path takes you to the Work Order Maintenance window.

Work order number

Work order number being viewed.

Link icon

Click to view any linked external files. Hold the shift key down and click to create a new file link for the record.

Up and down arrows

These arrows allow you to scroll through the work orders.

Notes

Shows status of Work Order, who created it and when.

Part and issue fields

Part number (parent assembly), Assembly part issue reference (when WO created) and Part description.

Show Extra Text button

To show the extra texts associated with the parent part. You will be able to change these texts. The Part Works Texts window will open.

Order quantity

Quantity ordered.

Planned start date

Latest kitting and start date.

The latest start date defaults to the current Make calendar day and the Completion due date defaults to the latest start date plus the assembly’s lead Make calendar working days. Both can be changed. The user will be warned if the lead time for the assembly exceeds the available workdays for completion.

Reference

User reference for WO.

Balance due

Balance due still for completion.

Completion due

Date of planned completion.

To Be Backflushed

To be backflushed flag.

If checked, the Work Order will be a Backflushed order where all component kit issues are recorded only at the time of completion of the assembly.

Comments

Comments printed on header of WO.

User fields 1-4

These fields are available for any use you wish to put them. They are passed to works history. They are not otherwise used or reported by the system and are provided for use with custom searches or reports or Ad Hoc reports. There are 4-character fields that are limited to 1, 4, 18, and 30 characters respectively. The field descriptions are set in File — System Manager — Company Details Maintenance window Descriptions tab pane.

User field one is one character long

User field two is 4 characters long

User field three is 18 characters long

User field four is 30 characters long.

Options – Ignored by MRP

Ignored by MRP flag.

If checked, MRP will not take account of the Work Order when considering the sources of supply for the assembly part. However, MRP will plan to have all the materials and components in inventory to enable the Work Order to proceed on time.

Options – List Kit on Printed WO

Provide component list on printed WO flag.

Controls whether a full Bill of Materials is listed at the end of the printed Work Order document.

Assembly details

This tab pane is the Assembly Details subwindow. See that topic for details.

Change Route… button

Click to amend the route operations that will apply to this Work Order.

This button control opens the Work Order Operation List Maintenance window to permit changes to the operational route for the WO.

There are some rules and restrictions that apply:

Any change can be made to the operations of a WO before it has been saved to the database.

If the WO has not been kitted or backflushed, changes can be made to the operations.

If any outwork operation has been placed on a Purchase Order or RFQ, that operation cannot have it’s operation number or work centre changed while it is still subject to a PO or RFQ.

If some of the WO has been received, or Shopfloor data collected for the final operation, the final operation number cannot be removed or changed, nor can a higher operation number be added to the WO route. However, the details of the final operation, including Work Centre, can be changed.

If an assembly has a Process Route, you cannot eliminate all operations for a particular Work Order. At least one must remain.

Actions

Kit Immediately

Check this for a full kit issue of the WO with no shortages when you save a new WO.

This option in processing is only available at the time you create the Work Order and only then if it is not to be Backflushed. If you check this control, at the time you confirm the creation of the Work Order, the full kit for the quantity of the assembly will be issued from inventory. No shortages are ever produced. However, the process of allocating stock is by-passed.

Print Picking List

Check this to print the WO Picking List when you save.

Print Work Order

Check this to print the Work Order when you save.

Revert button

To revert any changes to the previously saved version.

Save button

To save the changes you have made to the data file.

Also see: |

|

Compiled in Program Version 6.00. Help date last modified on 28 July 2022.

Class wWkoMaint last modified 25 May 2022.