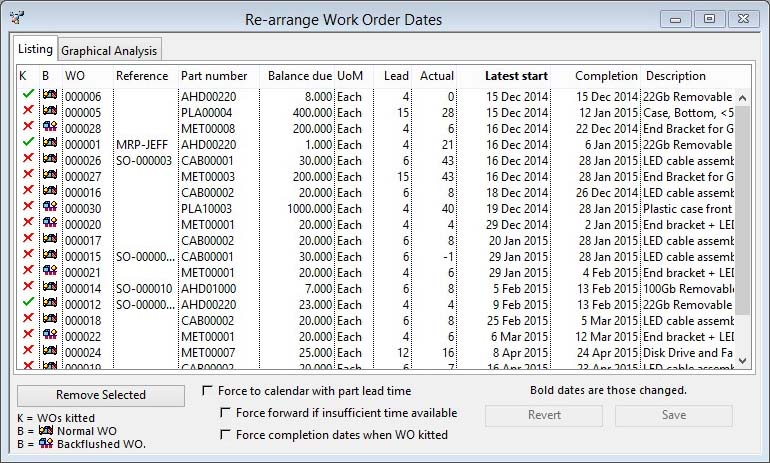

Re-arrange Work Order Dates

This window is opened by the Process — Work Order — Move Work Order Dates menu function and initially lists all Work Orders in the system.

In this window Work Order dates can be changed in a single process after entering the changes in a list or Graphical Analysis pane.

This window allows you to do powerful things to your production schedule, so take great care with it! All Work Orders are listed, those marked for Backflushing have a different icon while those already kit-issued have the tick icon. The only values that can be changed in this window are the Latest start dates (only for non-kit-issued Work Orders) and the Planned completion dates.

You can change the sort order of the listed Work Orders by clicking in the column header text to sort on that column.

By clicking and pausing in a date with the mouse you can change them manually. No change is made to the Work Order data file record until you Save Changes. If you want to go back to what is saved on file, click on the Revert button.

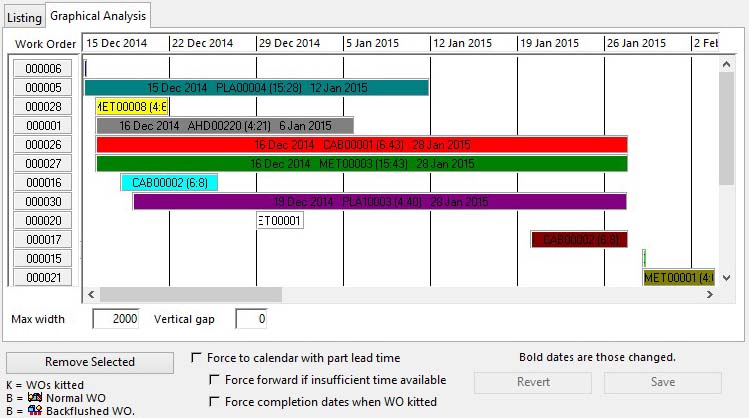

In the Graphical Analysis pane you can drag and drop work orders to change their dates.

|

Field |

Description |

|---|---|

|

Force to calendar with part lead time |

Uses the part lead time and the make calendar to calculate the other date to the one you change. This causes the system to check the completion dates against the Make Calendar and bring the date forward to an active make day if the one entered is not an active day. The Latest start date is then calculated using the calendar and the parts lead time. When you are entering Latest start dates manually, this option forces the completion date to be re-calculated automatically using the same calendar and assembly lead time. |

|

Force forward if insufficient time available |

Force the completion date forward if there is insufficient time based on the date you entered and the part’s lead time. This option only has any effect when the Force to Calendar with Lead Time option is selected. This option adds a further control to accommodate Work Orders where the evaluated Latest start date is before today’s date. In this event, the Latest start date will be sent to today and the Completion date re-calculated forward from today. |

|

Force completion dates when WO kitted |

Force the completion date forward for kitted works orders in the same way as unkitted. This option only has any effect when the Force to Calendar with Lead Time option is selected. Normally, Work Orders that have been kit-issued are ignored in the re-calculation of dates. If this checkbox option is selected, such orders will have their completion dates re-calculated. |

|

Button |

Action |

|---|---|

|

Remove Selected from List |

Removes the selected work orders from the list. This does not affect the data on file. |

|

Revert |

To revert any changes to the previously saved version. |

|

Save Changes |

To save the changes you have made to the data file. |

The window has 2 tab panes.

Listing

List all WOs on file. Click on a date to change it in the list.

![]() TIP: To edit cells in the list, select the line and click in the cell and hover the mouse over the cell. I.E. click once and pause with no mouse movement. The cell will then expand into an editable box in which you can enter different data. On leaving the box with any action like a tab or click elsewhere, the data is verified and the list returns to normal with the new data shown in the cell.

TIP: To edit cells in the list, select the line and click in the cell and hover the mouse over the cell. I.E. click once and pause with no mouse movement. The cell will then expand into an editable box in which you can enter different data. On leaving the box with any action like a tab or click elsewhere, the data is verified and the list returns to normal with the new data shown in the cell.

Graphical Analysis

Builds a timeline graphical representation of the listed work orders. See the Work Order Graphical Layout subwindow for full details and operation.

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:49:00.00. Class wWkoDates last modified 23 Sep 2017 10:51:13.