OVERVIEW

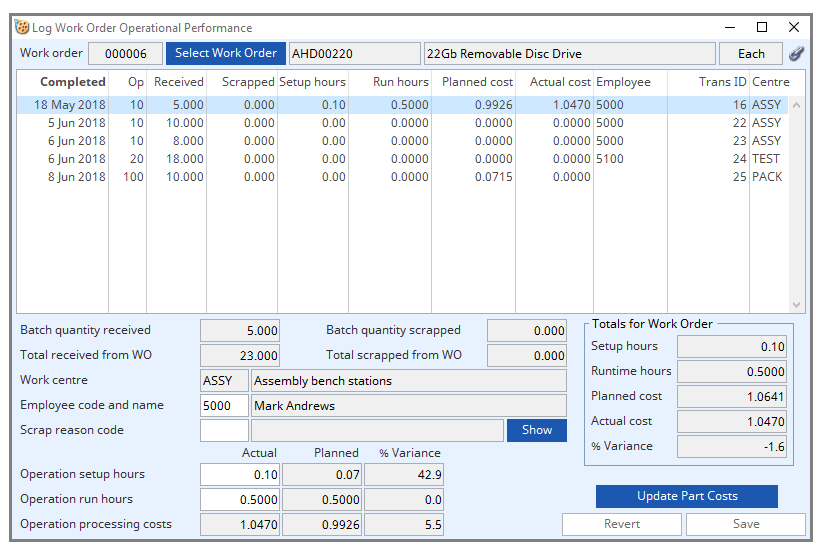

Work Order history records contain fields that can hold production performance data for each Operation on the Process Route. This data must be entered after the Work Order assembly has been received into stock or Operations have been recorded in the Shopfloor Data function. This Work Order Operational Performance window provides access to all Work Order history records. You must enter a Work Order number first in the Work History WO Selection window. A list of all history records for the selected Work Order is then presented.

If the Work Order has been received in more than one batch, multiple history records will be recorded and listed.

Select a record by clicking on the list line. Enter an Employee Code, if desired, and tab to enter the actual setup and run hours for the Operation. You can use HMSP syntax here (see below). The standards current in the process route Operation hours recorded at the time of the assembly receipt are provided for comparison. A percent variance to Process Route planned is provided.

If the history record has a scrap quantity, you are expected to enter a Scrap Reason code. This is not mandatory, but you will be reminded if you forget. Scrap Reason codes must be pre-defined in the File — System Manager — Index Codes section.

Once you have completed all operations for the work order use the Save Changes button to save your entries.

You can obtain a more comprehensive analysis of costs by clicking on the Update Part Costs button. The analysis is based on the average costs for all Operation receipts and the actual parts issued to the Work Order. This analysis is based on history and does not use the same processing as other Update cost analyses that uses the Bill of Materials and Process Route values. See the Part Costs Update window for details.

File Path

Process > Shopfloor > Log WO Performance…

This file path takes you to the Log Work Order Operational Performance window

Work Order

Work order number. {WOHFILE.WOHWONO char 6}

Select Work Order

To select a specific Work Order. It opens the Work History WO Selection window.

Part Number

Part number of assembly produced. {WOHFILE.WOHPTNO char 18}

Part Description

Part description. {PTMFILE.PTMDESC char 30}

UoM

Standard stock unit of measure. {PTMFILE.PTMSTUM char 6}

Link Icon

Click to view any linked external files. Hold the shift key down and click to create an new file link for the record.

Operation List

Lists operation records for all receipts of completed assemblies under this Work Order. Click on an operation line to select and enter actual results.

Batch quantity received

Quantity completed. {WOHFILE.WOHQTY number 3dp}

Batch quantity scrapped

Assembly scrap quantity. {WOHFILE.WOHSCRA number 3dp}

Total received from WO

The total assemblies received in all receipts.

Total scrapped from WO

The total assemblies scrapped in all receipts.

Work Centre Code

Work centre unique identifier code. {WKCFILE.WKCCODE char 4}

Work Centre Description

Description of work centre. {WKCFILE.WKCDESC char 30}

Employee code

Employee code. {WOHFILE.WOHEMPL char 4}

Employee name

Employee name. {EMPFILE.EMPNAME char 50}

Scrap reason code

Scrap reason code (relation: IDXID = con(‘7’,WOHSCRE). {WOHFILE.WOHSCRE char 4}

Scrap reason

Index code, scrap reason or QA test description (must have at least 1 character). {IDXFILE.IDXDESC char 255}

Scrap reason Popup List

List of available scrap codes. Double-click to assign.

Show button

Click to show a list of available scrap reason codes.

Operation setup hours – Actual

Setup time for operation batch in hours. {WOHFILE.WOHSTIM number 2dpShortnum}

You can use HMSP syntax here.

Operation setup hours – Planned

Standard operation Setup time (hours). {WOHFILE.WOHSTST number 2dpShortnum}.

You can use HMSP syntax here.

Operation setup hours -% Variance

Any variance between the actual setup time entered and the planned time in the process route.

Operational run hours – Actual

Runtime for operation batch in hours. {WOHFILE.WOHRTIM number 4dp}

You can use HMSP syntax here.

Operational run hours – Planned

Standard operation Runtime for ordered qty. {WOHFILE.WOHSTRT number 4dp}

You can use HMSP syntax here.

Operational run hours – % Variance

Any variance between the actual run time entered and the planned time in the process route.

Operational processing costs – Actual

The calculated costs for the batch operation based on the actual results recorded above.

Operational processing costs – Planned

The calculated batch operation costs for the Process Route operation times quantity of the batch.

Operational processing costs – % Variance

Any variance between the actual and planned costs of the batch operation.

Totals for Work Order

Setup hours

The total setup hours recorded against all operation completions.

Runtime hours

The total run hours recorded against all operation completions.

Planned cost

The unit parent operation cost as calculated from the Process Route.

Actual cost

The unit parent operation cost calculated from the actual times entered.

% Variance

Any variance between the actual recorded operational cost entered and the planned operational cost of the process route.

Update Part Costs button

To provide an analysis of costs based on the actual results of this Work Order. You can update part current costs, if desirable. It opens the Part Costs Update window.

Revert button

To revert any changes to the previously saved version.

Save button

To save the changes you have made to the data file.

Entering Time Values using HMSP Syntax

The system stores and uses times in decimal hours. 1.5000 hours rather than 1hr 30min. However, you can enter time in several different ways that will automatically convert to the equivalent decimal hours when you leave the field.

Units | Syntax | Example with Converts to |

Hours | h or H | 1hr30m = 1.5000 |

Minutes | m or M | 20m = 0.3333 |

Seconds | s or S | 3.6s = 0.0010 |

Hours:Mins | : or ; | 1:30 = 1.5000 |

Combined | All | 1:30m36s = 1.5100 |

Pieces per hour | p or P | 100p = 0.0100 |

Compiled in Program Version 56.00. Help data last modified 27 Jun 2022.

.Class wWohPerform last modified 25 May 2022