OVERVIEW

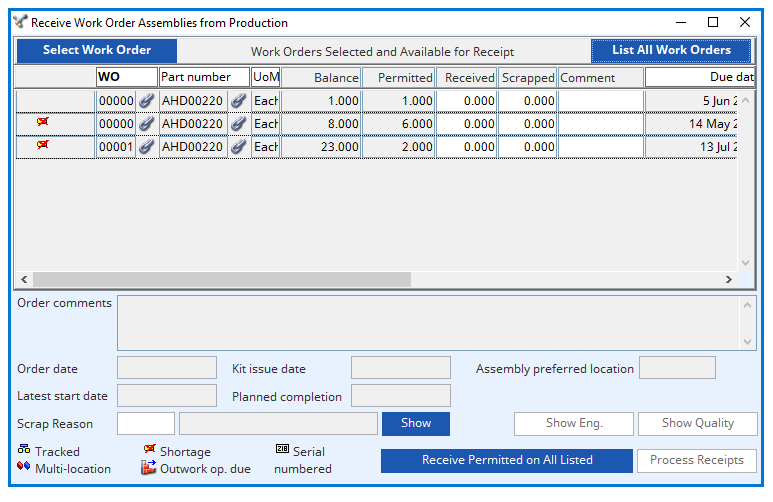

When the product of a Non-Backflushed Work Order is completed, this window is used to record the receipt into stock of the assembly. Receiving multiple Work Orders at the same time is possible. You gain access by operating the Process — Work Orders — Receive WO Assembly menu function.

You can individually select work orders with the Select Work Order button or all kitted Work Orders using the List All Work Orders. You process one or more receipts by entering the Quantity received and scrapped and, if required, a history comment.

In the File — System Manager — Company Details you may have set a WO + Receiving variance limit. In which case the permissible total quantity may be more than the Quantity Ordered.

TIP: The Work Order Receiving Variance limit can be usefully used when you build a level of scrap into the Bill of Materials. If you then get a better-than-expected yield from the production process, you can record it correctly.

Any Work Orders which have components logged as Shortages will be shown with an appropriate icon. These orders can still be received but only up to the quantity that the shortage would permit. The system only calculates this based on the immediate Bill of Materials. If the shortage originated from a Phantom assembly, you will get a message when you attempt a receipt.

The lead time since kit issue is automatically calculated from the Make calendar. Any number of sub-batch receipts can take place from a Work Order until the accumulated quantity of both received and scrapped is equal to the original order quantity. At this point the Work Order is automatically deleted from the file.

With each receipt, work history records are produced; one for each Operation on the current Process Route. If history records have already been recorded in the Process — Shopfloor — Shopfloor Data function, only the balance of missing Operation receipt history records are created. History records are never created for Operations carried out in Outwork Work Centres as these are created during the receipt from a Purchase Order.

If you record a scrap quantity, you are expected to enter a Scrap Reason code. This is not mandatory, but you will be reminded if you forget. Scrap Reason codes must be pre-defined in the System Manager: Index Codes section.

Once you have entered all the receipts in the list, you can process them by clicking on the Process Receipts button.

For Multi-location or Tracked parts that are received, the Location/Batch Assignment dialogue will be presented which must be completed before you can proceed.

File Path

Process > Work Orders > Receive WO Assembly…

This file path takes you to the Receive Work Order Assemblies from Production window.

Select Work Order button

To select several individual work orders to list for assembly receipt. It opens the Select Work Order window.

List All Work Orders button

To list all kitted non-backflushed work orders for assembly receipt.

Work Orders Selected and Available for Receipt field

A list of work orders. Enter a received quantity in the list.

Work Order Number

Work order number. {WKOFILE.WKOWONO char 6}

Assembly Part Number

Part number (parent assembly). {WKOFILE.WKOPTNO char 18}

UoM

Standard stock unit of measure. {PTMFILE.PTMSTUM char 6}

Balance

Balance due still for completion. {WKOFILE.WKOBAL number 3dp}

Permitted

The quantity of receipt permitted after accounting for unissued shortages and outwork operations.

Received

Quantity completed. {WOHFILE.WOHQTY number 3dp}

Scrapped

Assembly scrap quantity. {WOHFILE.WOHSCRA number 3dp}

Comment

The inventory comment that will be used when recording the assembly receipt.

Due Date

Date of planned completion. {WKOFILE.WKOCDAT date date1980}

Reference

User reference for WO. {WKOFILE.WKOUSER char 15}

Ordered

Quantity ordered. {WKOFILE.WKOOQTY number 3dp}

Description

Part description. {PTMFILE.PTMDESC char 30}

When the cursor is in a list line the fields below show for that work order:

Order Comments

Comments printed on header of WO. {WKOFILE.WKOCOMM char 2000}

Order date

Ordered date. {WKOFILE.WKOODAT date date1980}

Kit issue date

Kit issued date. {WKOFILE.WKOISDT date date1980}

Assembly preferred location

Stores single or preferred location. {PTMFILE.PTMSLOC char 8}

Latest start date

Latest kitting and start date. {WKOFILE.WKOLATE date date1980}

Planned completion

Date of planned completion. {WKOFILE.WKOCDAT date date1980}

Scrap reason code

Scrap reason code (relation: IDXID = con(‘7’,WOHSCRE). {WOHFILE.WOHSCRE char 4}

Scrap reason description

Index code, scrap reason or QA test description (must have at least 1 character). {IDXFILE.IDXDESC char 255}

Show button

To show a list of available codes from which to select.

Show Eng. button

Enables you to view Engineering data for a selected part, which may contain inspection instructions. It opens the View Engineering Data window.

Show Quality

Enables you to view the Quality Assurance Test Regime for a selected part. It opens the Part Quality Assurance Regime Maintenance window.

Receive Permitted on All Listed

Click this button to populate the Received column up to the permitted quantity less any scrapped you may have entered, for all listed WOs.

Process Receipts

Having entered all receipts onto the list, use this button to process all receipts in one operation.

See Also: |

|

Compiled in Program Version 6.00. Help data last modified 28 June 2022.

Class wWoAssyRecv last modified 25 May 2022