OVERVIEW

The Company Details Maintenance window provides an ability for the System Manager to edit central data specific to your business conditions.

A ten-tab window is presented covering company base data, system settings and window default data which is used at various points in the program to ease keyboard data entry.

WARNING: Certain data items can only be changed and saved when you are the only user on the system. If you change a value, the Save Changes and Revert to Saved buttons become enabled. A message will also appear to indicate “Saving your changes requires Single-User operation”. In this case you can only save changes if you are the only user on the system.

Company details data is held in a single record in its own file. When a new data file is created, Caliach Vision creates a single record of company details with default data already entered.

When satisfied with any changes click on the Save Changes button.

File Path

File > System Manager > Company Details…

This file path takes you to the Company Details Maintenance window.

This window has 10 tabs

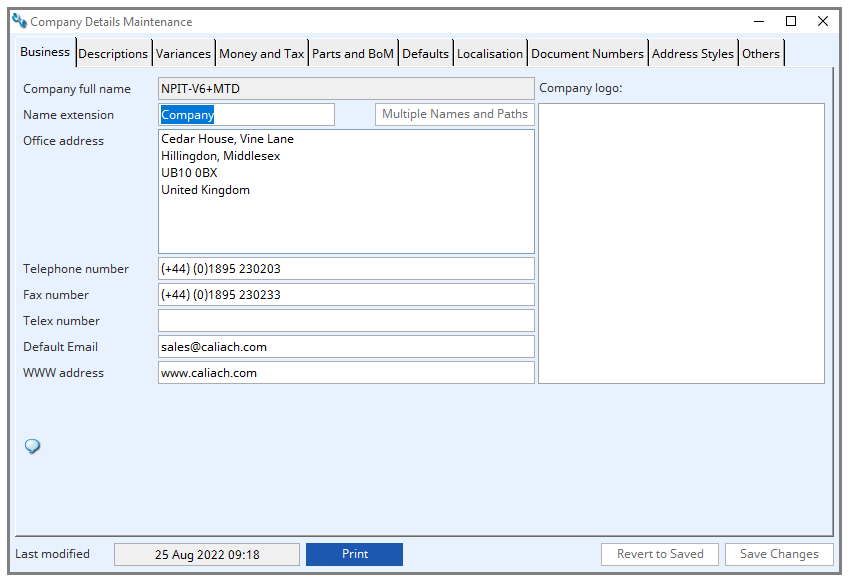

Business tab

Company full name

User company full name.

Your company full name of up to 40 characters that will be used on reports and windows. This is not editable and is provided as part of the license document Caliach.inf. Application must be made direct to Caliach if the contents require change.

Name extension

Company short name.

This is a short (15 characters) extension of the company name that is appended, with a space, to the company full name and used on all reports.

Multiple Names and Paths button

If you have multiple company name licencing, use this to set the name extensions and datafile paths.

Office address

The address is used in the printing of documents such as purchase orders, invoices, etc. This cannot be more than 120 characters, or 4 lines long otherwise extra lines will be truncated on documents.

Telephone number

Main company telephone number.

Fax number

Company fax number.

Telex number

Company telex number.

Default Email

Company default email address.

WWW address

World wide web URL for the company.

Company logo

Company logo – this will show on some standard reports.

Last modified

Date and time this window was last modified.

Print button

To print a report of all company details. Right click for report destination.

Revert to Saved button

To edit the company details. No other users can be operating on the data file.

Save Changes button

To save changes to the company details. No other users can be operating on the data file.

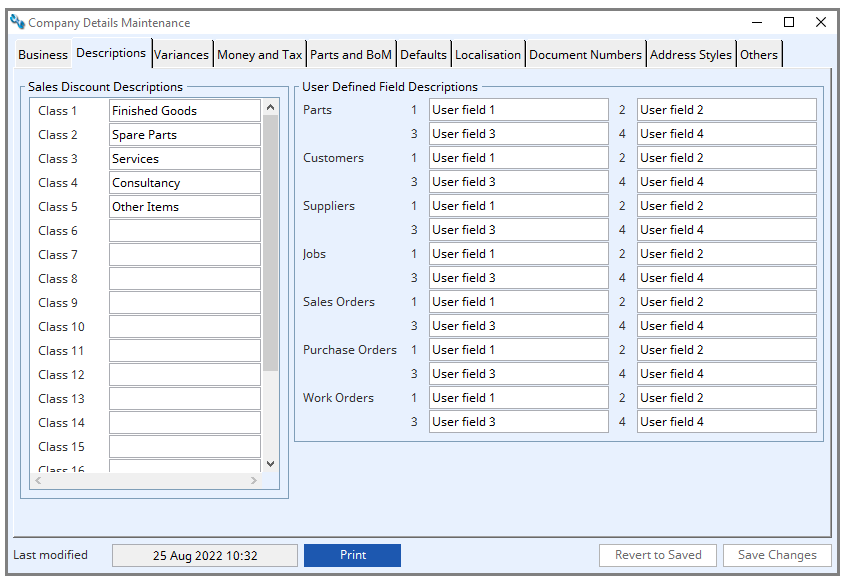

Descriptions tab

Sales Discount Descriptions

Discount class 1 to 20 description.

Each Part is assigned a discount class of 0 to 20 (1 is default). Each customer is assigned discount rates for each class (other than 0 which is taken to be zero discount rate). When Sales orders are prepared the appropriate discount for the Part to that Customer is then applied by default, plus any quantity additional discount. The 20 non-zero discount classes can be assigned descriptive text as an ‘aide memoir’ during window entry. 15 characters are permitted for each descriptor.

User Defined Field Descriptions

User defined field descriptions row (columns Pa1 to Pa4 for ‘Pa’rts, ‘Cu’stomers, ‘Su’ppliers, ‘Jo’bs, ‘So’s, ‘Po’s, ‘Wo’s).

Parts, Customers, Suppliers, Jobs and Estimates, Sales orders and Quotations, Purchase Orders and RFQs, and Work Orders have 4 user defined fields. Field 1 is a single character, 2 is 4 characters, 3 is 18 characters and 4 is 30 characters. You can enter here a description for each of these fields and this description will be reproduced on windows that display the fields. These fields are provided typically for custom search and/or reporting requirements and are not otherwise processed by the system.

The option value is set to 1234, or any combination of those numbers. It will cause those Job, PO, SO or WO user defined fields to be inherited from the customer, supplier, or assembly part fields.

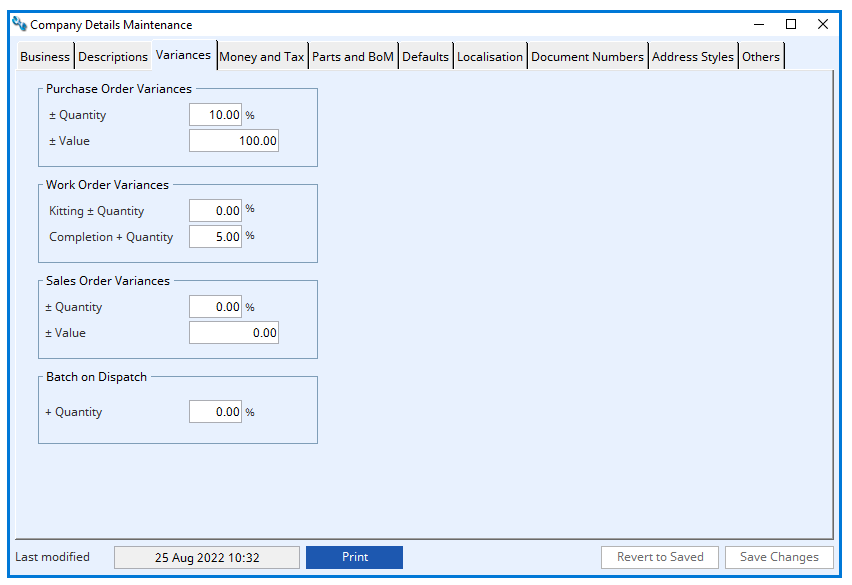

Variances tab

Purchase Order Variances – Quantity

Goods rec. qty. variance % limit.

During the goods receiving process, you may wish to have the option of completing a PO line item with a delivered quantity that is not exactly the ordered quantity. This can be useful to avoid leaving trivial quantities on back-order or, if the received quantity is in excess of that ordered, having to adjust the order prior to receiving it. To provide this feature, you can enter a variance limit in both quantity percent and value terms. For each PO line item, the system will apply the lower of the two values and permit, after a warning, line-item completion with that transaction. Purchase history and Inventory will reflect the actual receipt quantity.

Purchase Order Variances – Value

The goods received quantity variance value limit.

Work Order Variances – Kitting quantity

WO kit variance % permissible without creating shortages.

During the Work Order kitting process, you may wish to have the option of issuing a quantity that is greater or less than the BoM quantity. This can be useful where BoMs reflect average use of raw material. Works history and Inventory will reflect the actual kit quantity.

Work Order Variances – Completion Quantity

WO receiving variance %.

During the WO assembly receiving process, you may wish to have the option of receiving a quantity that is greater than the ordered and kitted quantity. This can be useful where BoMs reflect average wastage of raw material. Works history and Inventory will reflect the actual receipt quantity.

Sales Order Variances – Quantity

SO dispatch qty. variance % quantity limit.

During the dispatch process, you may wish to have the option of completing a SO line item with a dispatched quantity that is not exactly the ordered quantity. This can be useful to avoid leaving trivial quantities on back-order or, if the dispatched quantity is in excess of that ordered, having to adjust the order prior to receiving it. To provide this feature, you can enter a variance limit in both quantity percent and value terms. For each SO line item, the system will apply the lower of the two values and permit, after a warning, line-item completion with that transaction. Sales history and Inventory will reflect the actual dispatch quantity.

Sales Order Variances – Value

Sales Order dispatch quantity variance as a % of quantity limit.

Batch on Dispatch – Quantity

Batch variance % permissible on dispatch.

During the dispatch process, you may wish to have the option of completing a SO line item with a dispatched quantity that is not exactly the quantity available from a whole batch. This can be useful to avoid having to split batches on dispatch where trivial inaccuracies in quantity of a batch is the case.

Money and Tax tab

System Currency

Symbols

Standard currency symbol for your business.

Caliach Vision is a multi-currency system enabling you to create POs and SOs in any currency defined in Currencies. The symbol entered here is the local currency that you normally work in. The text is used in documents. Any Sales or Purchase record has the currency code (or symbol) written to it. Hence, if you change the standard currency symbol the system will warn you and, if confirmed, replace the old code on all records with the new one. This can take some considerable time if there are many history and/or ledger transaction records.

Decimal

Monetary cent character (e.g. p).

Full name

The name of the currency.

Part Sales Price Group Currencies

Part sales currency price 1 to 5 currency.

5 currency parts pricing is possible in the parts master. Each part can be given a local sales price (in standard currency) and five prices in foreign currencies. You must enter here the currencies you want to apply to the 5 currency prices. They must be pre-defined as currencies in the appropriate “System Manager” section. When a SO is created in a foreign currency and that currency is one of these five and there is a non-zero price in the appropriate part currency price field, that price will be applied to the SO line item. Otherwise, the current currency exchange rate will be applied to the local price.

Currency Maintenance button

Click to review or modify currencies. It will open the Currency Control window.

Sales and Purchase Tax

Tax name

Sales Tax abbreviated name for Invoices.

Registration number

Sales Tax (VAT) registration number.

VAT (for European users) registration is a mandatory requirement on invoice documents. If nothing is entered here the VAT registration number line is not printed on invoices. The I.D is used to identify the type of tax on documents and windows.

EORI Number

Relevant EORI number.

Default sales non-part class

Default sales non-part tax class code. See the Tax Maintenance window for full details of the tax handling system.

Default purchase non-part class

The default purchase non-part class code.

Default sales part class

The default sales part class code.

Default purchase part class

The default purchase part class code.

Default customer regime

Default customer tax regime. See the Tax Maintenance window for full details of the tax handling system.

Default supplier regime

Default supplier tax regime.

Tax Maintenance button

Click to review or modify the tax structure and rates. It will open the Tax Maintenance window.

Sales Commission System Default

Non-part item class

Commission class default for non-part items (for choice of commission agent applicability on Job and SO non-part items). See the Commissioned Sales Agents Maintenance window for full details of the commission handling system.

Other sales items button

Commission class table. Commission class description.

Commissioned Agents Maintenance

Click to review or modify commission classes and agents. It will open the Commissioned Sales Agents Maintenance window.

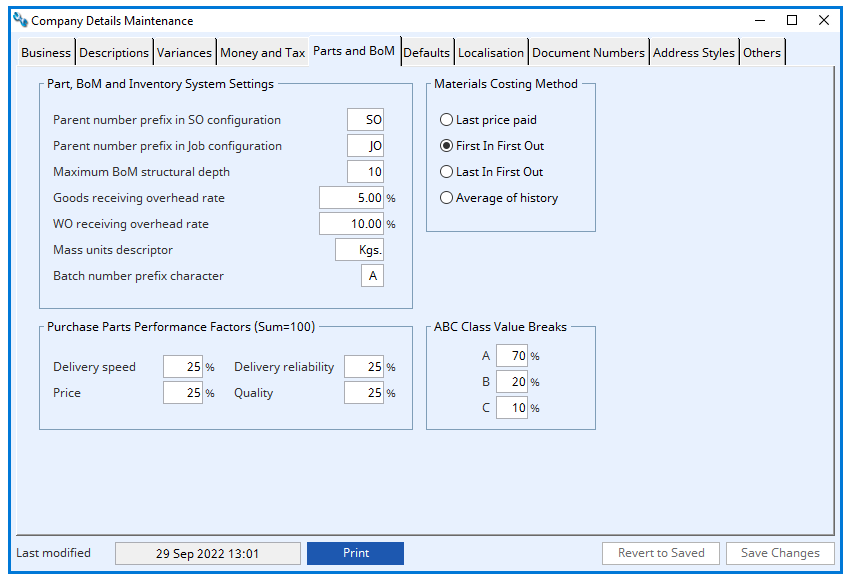

Parts and BoM tab

Part, Bom and Inventory System Settings

Parent number prefix in SO configuration

Prefix characters for parent part number created in SO configuration.

When you use Sales Order Configuration to create a SO specific assembly from a set of options, the resultant assembly is given a part number constructed in the form XXX-123456-789. Where “XXX” is the prefix entered here, “123456” is the SO number and “789” is the line item of the order. The prefix cannot contain a “WO” as this would cause a clash with work order operation outwork purchasing. If the prefix is left blank, SO Configuration will not be accessible to any user on the system. Sales Order Configuration is set up in the Sales Order Configuration Options window.

Parent number prefix in Job configuration

Prefix characters for parent part number created in Job configuration. See above for more details.

Maximum BoM structural depth

Maximum BoM level number.

Having very deep multi-level Bills of materials may be appropriate for your products or manufacturing process. However, the deeper the Bills the longer processing can take and the greater the number of transactions needed to create an end product from purchased components or raw materials. As a deterrent against excessive BoM depth the manager can set a limit to the depth at which Bills can be created. Components cannot be added to a Parent part if the Parent equals or exceeds the limit entered here. In any event the maximum is 99. It is suggested that this is initially set low until it is found to be inadequate. In this way the business can start with optimum performance. When, during BoM maintenance, the limit is encountered the System Manager may increase the Maximum BoM Level value.

Goods receiving overhead rate

Goods receiving default overhead percent (can be overridden by PTMROVR)

This is an overhead (burden) rate that is applied to all purchased parts during Cost Roll-Up or when their price is confirmed after a PO receipt. If the part has a non-zero individual rate (PTMROVR), then this will apply rather than this global rate. If PTMPOVR is negative, the overhead rate will be zero. The subsequent overhead amount is stored in the “Receiving overhead” field in the Parts Master record. The rate can be any range from 0.00 to 999.99% and applies to the prime (material) cost. This rate can be used to account for goods receiving costs such as inward freight, PO and stores administration, etc..

WO receiving overhead rate

WO receiving default overhead percent (can be overridden by PTMROVR).

This is an overhead (burden) rate that is applied in a similar manner to the Goods receiving overhead rate but in this case applies to assembly parts. It is only used during Cost Roll-Up. If the part has a non-zero individual rate (PTMROVR), then this will apply rather than this global rate. If PTMPOVR is negative, the overhead rate will be zero. The subsequent overhead amount is stored in the same “Receiving overhead” field in the Parts Master record. The rate can be any range from 0.00 to 999.99% and applies to the This-level material, labour and labour overhead cost. This rate can be used to account for WO handling and stores costs.

Mass units descriptor

Mass units for window/report display.

This is a window and report descriptor for the units of mass (weight) used throughout the system. Parts can be given a value for their mass and process route operations can be given a value of mass change. You should settle on a standard for your business, e.g. Kgs., Lbs. etc..

Batch number prefix character

Batch numbers are seven characters long, created automatically by the system for inward part inventory transactions when the part is flagged as tracked. There are two batch numbering system options, controlled by a system preference, both generate a number up to 6 digits long. The prefix character is appended to the generated number. You can use this prefix to group batch numbers. You are restricted to numerals 0 through 9 and upper case letters A through Z only. In addition, you cannot use any character that has already been used and is currently on file. See also System Preferences topic for control of the batch numbering system.

Purchase Parts Performance Factors (Sum=100)

Factors are used to load the four Purchase parts performance indicators to produce the overall performance of the supplier for a part. The factors are used on the purchase parts maintenance window and during the global changes function for calculating performance. The factors must add up to 100. If all four are given the value 25, then each indicator will be equally weighted. If one is given 100 and the others 0, the overall rating for the supplier will be solely based on that indicator.

Delivery speed

Delivery speed performance factor (0-100).

Delivery reliability

Delivery reliability performance factor (0-100).

Price

Price performance factor (0-100).

Quality

Quality performance factor (0-100).

Materials Costing Method

When costs for parts are updated either in product costing roll-up or updating costs, the basis on which purchased parts and material current costs are updated is governed by your selection here. Last price paid simply takes the unit cost in the last purchase history record. First in First out (FIFO) takes account of the current inventory physical quantity and calculates the current costs based on the preceding history of purchases assuming that receipts into inventory are consumed in the order they are received. Last in First out (LIFO) uses purchase history in the same way as FIFO but assumes that newest receipts are consumed first. Average of history uses all purchase history records for the part and calculates a weighted average cost for the part. See the Product Costing window for more details.

Last price paid

Stock valuation method (0=Last,1=FIFO,2=LIFO,3=Average).

First In First Out

Stock valuation method (0=Last,1=FIFO,2=LIFO,3=Average).

Last In First Out

Stock valuation method (0=Last,1=FIFO,2=LIFO,3=Average).

Average of History

Stock valuation method (0=Last,1=FIFO,2=LIFO,3=Average).

ABC Class Value Breaks

The ABC codes for parts can be assigned automatically as part of MRP processing. The total value of the recommendations from the MRP plan (see MRP processing help) on a “This-level” basis is calculated. Then the parts accounting for the most ‘A value break’ value of the total are given ‘A’ class, those remaining that account for above ‘B value break’ value of the total are given ‘B’ class, those remaining that account for above ‘C value break’ value of the total are given ‘C’ class. Parts contributing less than ‘C value break’ or are not involved in the MRP results are cleared of any class. When editing ‘A’ must be greater than ‘B’ which must be greater than ‘C’.

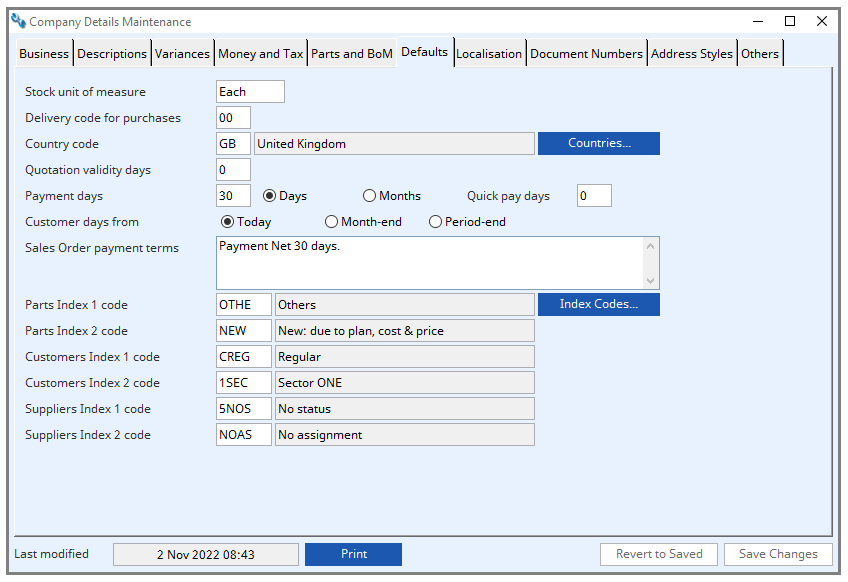

Defaults tab

System defaults for documents and new master records. When new file records are created using window entry, some entry boxes are initialised with a value. This is done to speed the entry process. Many are set by the system. However, some can be set by you in this area.

Stock unit of measure

Default stock unit of measure.

This appears for new parts on the Parts master maintenance window and can be up to 6 characters in length.

Delivery code for purchases

Default delivery point code.

This is the code identifying the delivery data record that will be applied, by default, to all purchase orders when being created. The delivery details must be pre-defined.

Country code

Default country code.

This code must be pre-defined in the Country codes maintenance window and is, by default, applied to new customer and supplier entries.

Country description

Country title.

Countries button

Click to review or modify the countries. It will open the Country Maintenance window.

Quotation validity days

Default quotation validity days.

Payment days

Default payment days for invoices.

Days

Customer payment days.

You can choose to either apply Customer payment Days or Months by selecting the appropriate radio button.

Months

Customer payment months rather than days.

Quick pay days

SO or Job default quick-payment days (or months) for invoices (0 = same as payment days).

Customer days from

Customer payment days from type (0=Today,1=Month-end,2=Period-end).

You have the option of choosing the point from which the default payment date is calculated for Invoices. The default is to calculate the date from Today, i.e. the Invoice date. Otherwise, you can have the date calculated as the payment days from the end of the current calendar month or the current sales ledger period-end. Period-end is the same as Month-end when you do not have the Ledgers license option.

Sales Order payment terms

Default sales order payment terms.

This is the default text (up to 1000 characters) that will be entered in each new Quotation or Sales Order if there is no specific Customer Payment Terms.

Part Index 1 code

Default part index code 1.

These are the default index codes assigned to new Parts, Customers and Suppliers. These fields must be filled.

Index Codes button

Click to review or modify the index codes. It will open the Index and Other Code Maintenance window.

Parts Index 2 code

Default Part Index code 2.

Customers Index 1 code

Default Customer Index code 1.

Customers Index 2 code

Default Customer Index code 2.

Suppliers Index 1 code

Default Supplier Index code 1.

Suppliers Index 2 code

Default Supplier Index code 2.

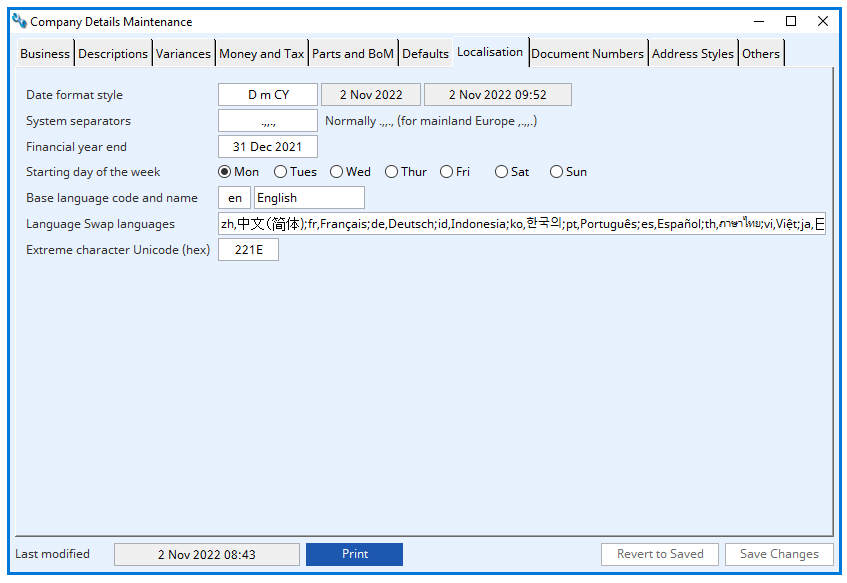

Localisation tab

Options for localisation such as date formats.

Date format style

Date presentation style of user.

The system allows you to determine the format of dates on windows and reports. A code can be entered in this field to determine the date style. The code is made up of the following characters:

Y = the year (93)

y = the year with century (1993)

C = the century part of the year (19)

M = the month number (01)

m = the three letter abbreviation of the month (JAN)

n = the month in full text (January)

D = the day number of the date (15)

d = the day as text (15th)

W = the day of the week (5)

w = the day of the week (Friday)

Examples are as follows:

m D,y displays JAN 15,1993

D m y displays 15 JAN 1993

M/D/Y displays 1/15/93

YMD displays 930115

D-m-19Y displays 15-JAN-1993

System separators

System separator characters (5 characters: 1 = decimal point, 2 = thousands separator, 3 = function separator, 4 = import/export decimal point, 5 = import/export comma delimiter).

You can change the usual . (full-stop, period mark) character as the decimal separator in numbers displayed and printed in the entire system. For some European countries a , (comma) character is used. (E.g. 10,50 for the more normal 10.50). There is a limited range of characters you can use. They are:

!”#$% ‘()*+,-.

Take great care with using these as they can cause a great deal of confusion. The use of the character you set here applies only to the use of a particular datafile and only within the system.

You can also change the usual , (comma) character as the thousands separator in long numbers displayed and printed in the system. For some European countries a . (full-stop, period mark) character is used. (E.g. 1.000.000,00 for the more normal 1,000,000.00).

Financial Year End

Financial year end (used in some date calculations). Actual year is unimportant.

Starting day of the week

First day of the week (used in date calculations) 1=Mon.

Base language code and name

Local base language: Use ISO 631-1 language code. e.g. en.

Local base language name. e.g. English.

Language swap languages

Language Swap code,name; language pairs e.g. fr,French;th,Thai.

For details see Introduction to the Language Swap System.

Extreme character Unicode (hex)

Extreme Unicode character for searches in hex format up to 10FFFF.

When searches are made and you enter a search range in a typical report selection window, if you don’t enter anything in the to range field the system will enter for you a single character that is presumed to be greater, in search terms, than the values in the data. To accommodate the universal character system of Unicode and when you use characters which are from high Unicode values, you may need to choose a higher value for this than our 221E default value. The maximum you can enter is 10FFFF and what you enter must be in hexadecimal format.

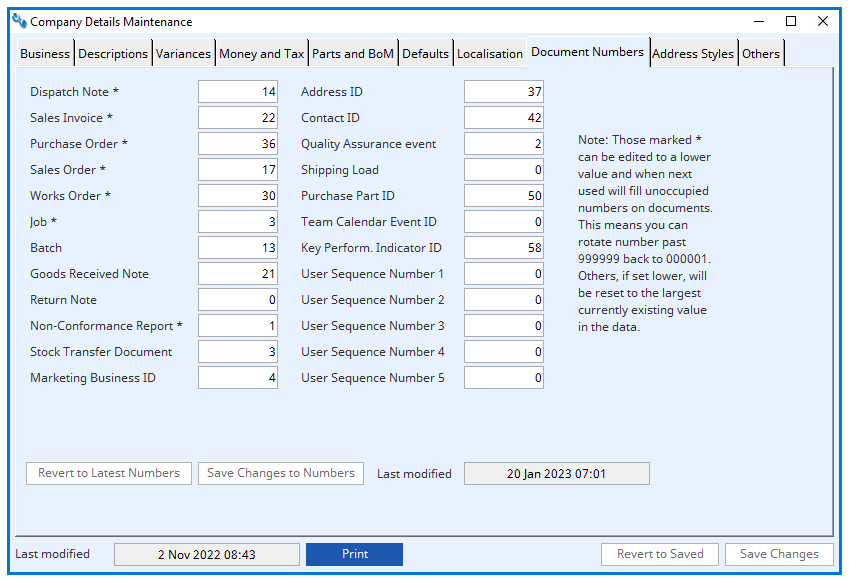

Document Numbers tab

To review or change the system’s document serial numbers. These document serial numbers are automatically incremented when documents are created in normal processing. They can be edited here. You can decrement the numbers, but great care must be taken that the subsequent values for documents do not already exist as historic documents.

Dispatch Note

Last Dispatch Note number used.

Sales Invoice

Last Sales Invoice number used.

Purchase Order

Last Purchase Order number used.

Sales Order

Last Sales Order number used.

Works Order

Last Works Order number used.

Job

Last Job number used.

Batch

Last Batch number used.

Goods Received Note

Last Goods Received Note number used.

Return Note

Last PO Return Note number used.

Non-Conformance Report

Last Non-Conformance Report number used.

Stock Transfer Document

Last Stock Transfer number used.

Marketing Business ID

Last Marketing Company created.

Address ID

Last additional Address serial number.

Contact ID

Last Marketing contact created.

Quality Assurance event

Last Quality Assurance event serial number.

Shipping Load

Last Shipping Load number.

Purchase Part ID

Last Purchase Part ID number.

Team Calendar Event ID

Last Team Calendar Event ID number.

User Sequence Number 1-5

Last User 1-5 sequence number used.

Revert to Latest Numbers button

Re-reads the latest serial number data from the database and overwrites any changes to numbers you may have made and not saved.

Save Changes to Numbers button

Saves any changes to document numbers you may have made. You must be the only users connected to the data file.

Last Modified

Last modified date and time.

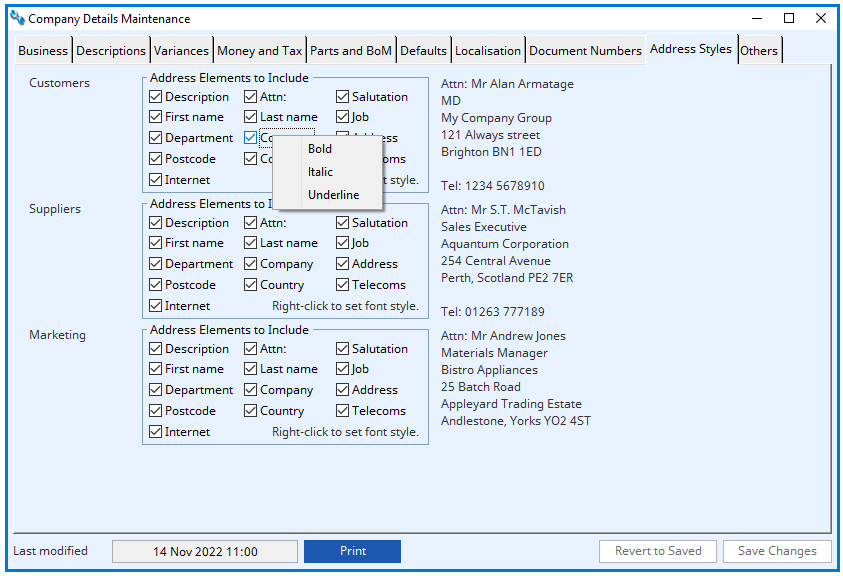

Address Styles tab

This window controls the default customer, supplier, and marketing address styles.

The checkboxes are used to indicate which element of the address and contact data should or should not be included in the address style for the linked document. Right-Click on each element to control font enhancements of Bold, Italic or Underline.

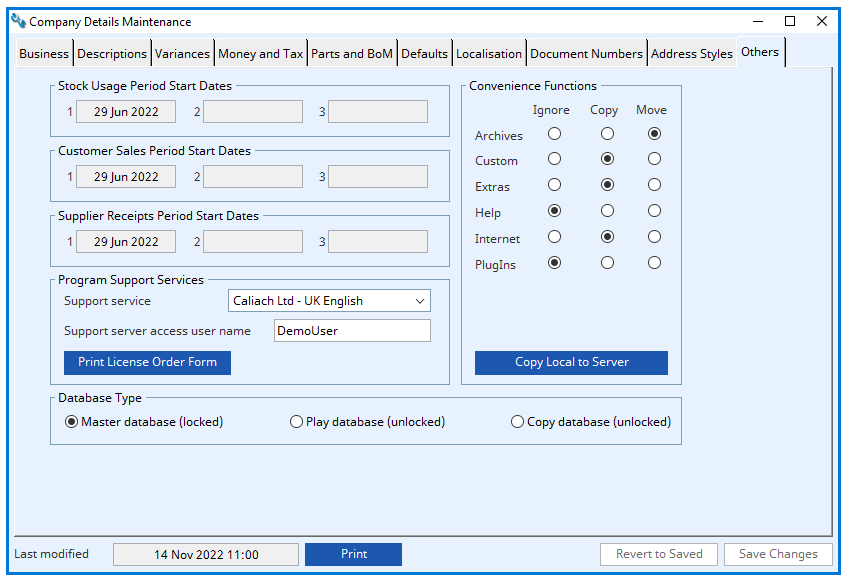

Others tab

Other system-wide values and program support services.

Period dates

All three sets of period start dates are displayed on this window as they are part of the Company details file. However, they cannot be changed. These dates are generated automatically when they are rolled-over during the period-end routine.

Stock Usage Period Start Dates

Part Usage period 1 to 3 start date.

Within the Parts master file data is maintained on the consumption of parts from inventory (stock) for three periods of time: Period 1 is from its start date to today’s date; Period 2 is from its start date up to, but not including Period 1’s start date; and Period 3 is from its start date up to, but not including, Period 2’s start date.

Customer Sales Period Start Dates

Customer period one to three start date.

Supplier Receipts Period Start Dates

Supplier period one to three start date.

Support Services

Support source identification (controls default update FTP site and fault email address).

Support Server access username

CMS Internet upgrade ftp server access username.

Print Licence Order Form button

Select to open the License Application Data Entry window.

Database Type

Select which database type this is.

Convenience functions

You can use this to copy or move certain directories of the Caliach Vision installation from their local installation location to the datafile directory, typically on a server. The contents of these directories will then be common to all users attached to the datafile. This can be useful to ensure backups are made regularly and it can be much more convenient for system management. However, using local directories will reduce network traffic. Moving a directory, rather than copying it will delete the local files. The process operates recursively on directories to any level.

Copy Local to Server button

This will copy the database to the local server with the relevant convenience functions selected.

Compiled in Program Version 6.00. Help date last modified on 14 November 2022

Class wMcdEdit last modified 25 May 2022 FP: File > System Manager > Company Details…