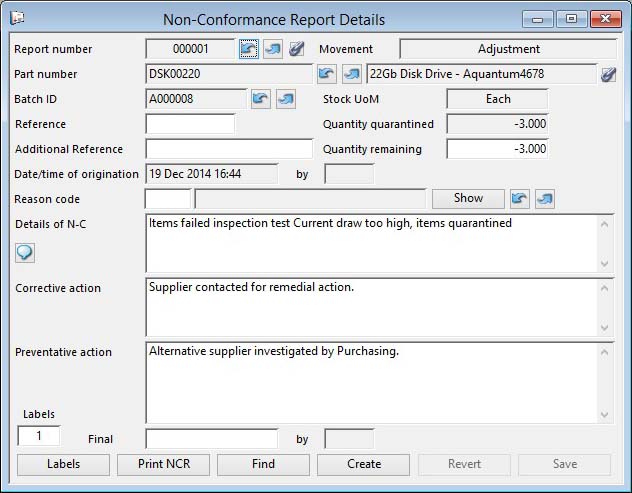

Non-Conformance Report Details

Non-Conformance Reports

When a quantity of a part is, at any time, moved into a Quarantine multi-location, a Non-Conformance Report record will be created. A unique number is assigned. This number can be pre-set in the System Manager, Company Details, Document Numbers window. Creation of a Non-Conformance Report record is optional. The user is prompted at the time. At the time the Quarantine is made the Non-Conformance Report details window will open and you can enter any comments you wish. Thereafter the records can be accessed by selecting the Non-Conformance Reports function from the QA and Tracking hierarchical menu.

![]() NOTE: During inventory movements data is manipulated inside a serialized transaction so that all data changes are applied, or none at all in fault conditions. If user-entry were allowed during this process deadlocks could occur, locking other users out of the database for an indeterminate period. So, when a part movement leads to quarantine stock, a NCR row will be created automatically within the transaction. After the transaction completes you will be offered the choice of deleting it or entering details of the non-conformance.

NOTE: During inventory movements data is manipulated inside a serialized transaction so that all data changes are applied, or none at all in fault conditions. If user-entry were allowed during this process deadlocks could occur, locking other users out of the database for an indeterminate period. So, when a part movement leads to quarantine stock, a NCR row will be created automatically within the transaction. After the transaction completes you will be offered the choice of deleting it or entering details of the non-conformance.

You can use the Create button to add a new Non-Conformance Report record. When you do this you must enter all the details yourself, unlike the automatic creation when parts are moved into quarantine.

From this window you can print labels for the report or an NCR certificate.

The Quantity Remaining and the Final Date/Time are not automatically determined. They can be edited, along with any comments.

|

Field |

Description |

|---|---|

|

Report Number |

Non-Conformance Reports. Non-conformance number. {NCRFILE.NCRNO char 6} |

|

Movement |

Non-Conformance Reports. Movement type causing NCR. {NCRFILE.NCRTYPE char 1} |

|

Part Number |

Non-Conformance Reports. Part Number. {NCRFILE.NCRPTNO char 18} |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Batch ID |

Non-Conformance Reports. Batch number when tracked. {NCRFILE.NCRBATC char 7} |

|

Stock UoM |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Source Reference |

Non-Conformance Reports. Source reference (Supplier code, WO Number, etc). {NCRFILE.NCRFROM char 6} |

|

Quantity Quarantined |

Non-Conformance Reports. Quantity into non-conformance. {NCRFILE.NCRQTIN number 3dp} |

|

Additional Reference |

Non-Conformance Reports. Source reference (Supplier code, WO Number, etc). {NCRFILE.NCRFROM char 6} |

|

Quantity Remaining |

Non-Conformance Reports. Quantity currently subject to non-conformance. {NCRFILE.NCRQTRE number 3dp} |

|

Date and Time of Origination |

Non-Conformance Reports. Date and time of origination of NCR. {NCRFILE.NCRDATG date datetime} |

|

Date and Time of Resolution |

Non-Conformance Reports. Date and time of final resolution of the NCR. {NCRFILE.NCRDATC date datetime} |

|

Details of Non-Conformance |

Non-Conformance Reports. Details of causes of non-conformance text. {NCRFILE.NCRCOMM char 10000000} |

|

Corrective action |

Non-Conformance Reports. Corrective action taken text. {NCRFILE.NCRCORR char 10000000} |

|

Preventative action |

Non-Conformance Reports. Preventative action taken text. {NCRFILE.NCRPREV char 10000000} |

|

Labels |

Enter the number of labels you want to print for the Non-Conformance Report. |

|

Button |

Action |

|---|---|

|

Labels |

To print a non-conformance label for the item. |

|

Print NCR |

Click here to print a Non-Conformance Report. |

|

Find |

Click here to find an NCR record by entering a value.

|

|

Create |

Click to create a new non-conformance report record.

|

|

Revert |

To revert any changes to the previously saved version. |

|

Save |

To save the changes you have made to the data file. |

|

Cancel |

Aborts the process currently in session. The keyboard equivalent is the Esc key for Windows computers and Command-.(full stop or period) for the Mac. |

|

OK |

The OK button updates the data you have entered, or confirms the selection and/or processes the function you have called. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 14 Jul 2016 07:50:00.00. Class wNcrEntry last modified 10 Oct 2017 11:48:26.