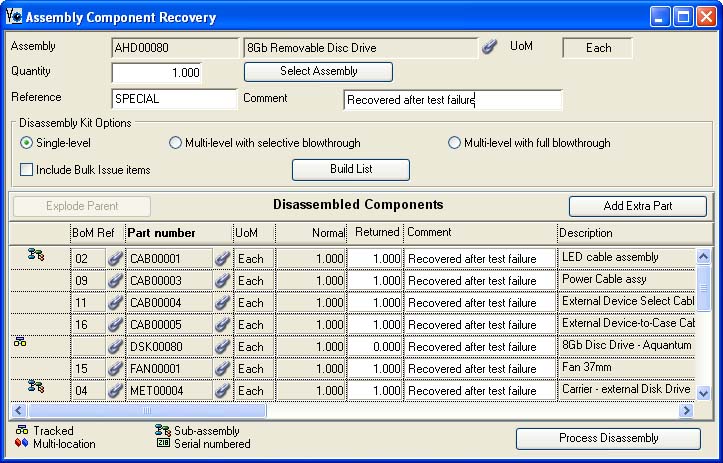

Assembly Component Recovery

This window is an optional feature that can be used for recovering the components of an assembly. You can add it as a function to the User main menu by adding the class wOptAssyExplode into the Custom Feature settings.

It simply issues the quantity of the Assembly part from stock and returns the list of Disassembled Components into stock. Typically not all can be fully recovered so you can adjust the quantities returned after a standard BoM is built. It operates in an opposite manner to a Backflushed Work Order.

![]() CUSTOM CAPABILITY: This is a customisation class which is provided in open-source form within your OpenVision.lbs library. It may have been originally developed for a specific Caliach Vision user and may be highly specific to their data. It is not covered by normal customer support.

CUSTOM CAPABILITY: This is a customisation class which is provided in open-source form within your OpenVision.lbs library. It may have been originally developed for a specific Caliach Vision user and may be highly specific to their data. It is not covered by normal customer support.

|

Field |

Description |

|---|---|

|

Assembly |

Parts Master. Part number unique identifier. {PTMFILE.PTMPTNO char 18 Idx} |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Stock Unit of Measure |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Quantity |

The quantity of the assembly issued from stock and disassembled. |

|

Reference |

The inventory document reference that will be applied when recording the assembly general issue movement and kit returns. |

|

Comment |

The inventory comment that will be used when recording the assembly general issue movement. |

|

Single-level |

Will yield a single-level kit similar to a normal WO. |

|

Multi-level with full blowthrough |

Will yield a full to-lowest-level kit. |

|

Multi-level with selective blowthrough |

Will initially yield a single level kit. You can then blow through sub-assemblies by reducing the quantity in the list line and then click on Explode Parent. |

|

Include Bulk Issue items |

Check this option to have Bulk Issue parts included in the kit list. |

|

Disassembled Components List |

A list of component parts to issue or return. Sorting the list will reset all editable values to the default. The list has the following fields: |

|

BoM Reference |

BoM Structure. Component reference within structure. {BOMFILE.BOMCREF char 4 Idx} |

|

Component part number |

BoM Structure. Component part number. {BOMFILE.BOMCPNO char 18 Idx} |

|

Stock UoM |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Normal quantity |

The kit quantity required for issue or available for return. |

|

Returned |

The quantity actually being returned. |

|

Comment |

The inventory comment that will be used when recording the part movement. |

|

Component description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Button |

Action |

|---|---|

|

Select Assembly |

To select an assembly part number. This opens the Assembly Selection window. |

|

Build List |

Having set up the quantities and options, click to build the kit list below. |

|

Explode Parent |

Having built the list with the selective netting option, use this button to explode the subassembly you have selected on the list. |

|

Add Extra Part |

To use a This opens the Part Selection window to add an extra item to the component list. Alternatively you can drag and drop from the Parts ScratchPad or BoM Listing. |

|

Process Disassembly |

Click to process the assembly issue and simultaneous kit return. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 17 May 2012 04:06:00.00. Class wOptAssyExplode last modified 10 Oct 2017 11:48:27.