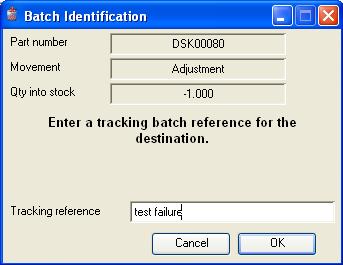

Batch Identification

This window opens whenever a tracked part stock change is individually processed and enables you to choose a batch source of the movement and or a tracking reference for the part trace log. Normally the tracking reference is automatically assigned (see below), but in cases where there is no source link, such as a purchase or work order, you will be asked to provide one.

|

Field |

Description |

|---|---|

|

Part number |

Parts Master. Part number unique identifier. {PTMFILE.PTMPTNO char 18} |

|

Batch dropdown list |

List of current batches. This is only visible when appropriate to the transaction. |

|

Tracking reference |

Batch Tracking. Batch trace identifier code: jst(‘D’,1,SAHCUSC,’6X’, SAHDESP,6,SAHLINE,’-3N0P0′) or jst(‘C’,1,SAHCUSC,’6X’, SAHINNO,6,SAHINVL,’-3N0P0′). {TCKFILE.TCKREF char 16} See movement type below. The tracking reference varies with each stock movement type. |

|

Movement type |

Stock Movement History. Movement type. {STHFILE.STHTYPE char 1} |

|

Movement quantity |

Stock Movement History. Quantity of movement (+ = into (or due into) inventory, – = out of inventory). {STHFILE.STHQTY number 3dp} |

|

Button |

Action |

|---|---|

|

Cancel |

Aborts the process currently in session. The keyboard equivalent is the Esc key for Windows computers and Command-.(full stop or period) for the Mac. |

|

OK |

The OK button updates the data you have entered, or confirms the selection and/or processes the function you have called. |

Tracking System

The traceability system in the program works by recording all movements of parts marked as Tracked. Each time a quantity of the part is moved a tracking record is produced with the following information:

|

Field |

Description |

|---|---|

|

Part Number |

The number of the part being processed. |

|

Batch |

The batch number from which or to which the quantity was moved.

|

|

Tracking reference |

A coded reference which can identify the source or destination of the movement. For example, it may identify the Supplier, Purchase Order and Line Item of a receipt. |

|

Transaction type |

A single character code that identifies the process causing the movement. The transaction type is the same as that used in Stock History. |

|

Quantity |

The quantity in stock units of measure of the movement into inventory. If this is negative the movement was out of inventory. |

|

Extended Stock Information |

Length, Width, Units, Date and Comments |

|

Movement (Type) {Qty} |

Batch ID |

Reference |

|---|---|---|

|

SO dispatch (A) {-ve} |

Source |

‘D’,CUSCODE,SAHDESP,SAHLINE or |

|

SO return (B) {+ve} |

New |

‘C’,CUSCODE,SAHIVNO,SAHINVL |

|

Job issue (A) {-ve} |

Source |

‘J’,CUSCODE,JOBCODE,JBILINE |

|

Job return (B) {+ve} |

New |

‘J’,CUSCODE,JOBCODE,JBILINE |

|

PO receipt (C) {+ve} |

New |

‘S’,POLREFor |

|

PO return (D) {-ve} |

Source |

‘S’,SUPCODE,POHPONO,POLLINE |

|

General Issue (E) {-ve} |

Source |

User entered or null |

|

Gen. Return (F) {+ve} |

New |

User entered or null |

|

Outwork issue (G) {-ve} |

Source |

‘S’,SUPCODE,POHPONO,POLLINE |

|

Outwork return (H) {+ve} |

Change qty or delete issue |

|

|

WO kit issue (I) {-ve} |

Source |

‘W’,WKOWONO |

|

WO kit return (J) {+ve} |

Change qty or delete issue |

|

|

WO receipt (K) {+ve} |

New |

‘W’,WKOWONO |

|

Allocation (L) |

||

|

De-allocation (M) |

||

|

Adjustment +ve qty (N) {+ve} |

New |

User entered or null |

|

Adjustment -ve qty (N) {-ve} |

Source |

User entered or null |

|

SO preparation (O) |

||

|

PO preparation (P) |

||

|

WO preparation (Q) |

||

|

Kitting qty adjustment (R) |

||

|

Quarantined (outward) (S) {-ve} |

Source (Non-Quar) if not float |

User entered or null |

|

Released (outward) (T) {-ve} |

Source (Quar) |

User entered or null |

Where:

CUSCODE = Customer code

SAHIVNO = Invoice Number

SAHLINE = Invoice Line Number

SUPCODE = Supplier Code

POHPONO = Purchase Order Number

POLLINE = Purchase Order Line Number

WKOWONO = Work Order Number

New Batch Numbers are constructed from XNNNNNN, where X is the Batch number prefix set in the “System Manager” “Company Details…” and NNNNNN is the next batch serial number.

For +ve qty movements a new batch location is created when received into inventory.

For -ve qty movements the batch location is the source from inventory.

User entered tracking references cannot be prefixed by the characters “C”, “S” or “W” which are reserved for automatic references.

![]() NOTE: The following options can be used to modify the Batch Number and Tracking system operation:

NOTE: The following options can be used to modify the Batch Number and Tracking system operation:

optSOBatchNosInDesc : If set to 1 or YES, Batch Numbers of tracked parts will be appended to the Sales History description and show on invoices.

optStockBatchDateWarn : If set to 1 or YES, a user warning is given on batch selection at the time of dispatch when date-based batch numbers are older than number of days set in PTMUSE2. This enables an expired batch to be identified so that expired stock is not shipped to customers.

optStockBatchNoManual : If set to 1 or YES, the user is permitted to enter a Batch Number for batch tracked items received from a Purchase Order or received from a Work Order. The number must be unique and have a different prefix character to that currently set in the Company Details.

optStockBatchWindowOff when Extended Stock Information system preference is on, will suppress the opening of the New Multi-location for Part window.

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:48:00.00. Class wTckSingle last modified 18 Feb 2015 01:54:55.