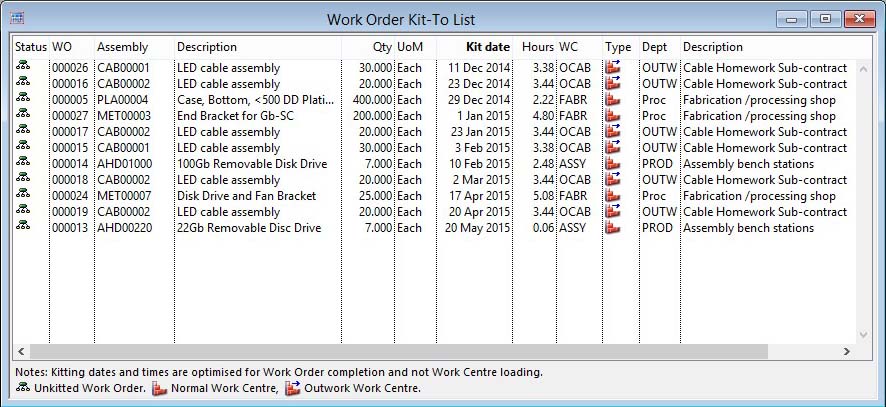

Work Order Kit-To List

Shows which Work Orders should be kitted and, if the sort is selected correctly, in which order, what assemblies are being manufactured and when the kits should be issued and to which Work Centre.

The Work Centre shown is that for the first operation. Remember that these dates may differ from MRP recommendations which are based on parent part lead time and not Operation times from Process Routes.

Additionally, Work Centre available hours are taken into account. However, for all orders only one Work Centre is assumed to be involved in each operation – no account is taken of the quantity of Work Centres.

This listing can be used as a schedule for the storeman to pick kits for production.

If you double-click on a Work Order or Job Operation, a review window will be opened showing the Work Order or Job Operation details. Re-scheduling can then be made interactively. This is only possible, of course, with genuine Work Orders or Job Operation.

This window can be left open and you can readily switch between it and others by clicking on the desired window with the mouse.

| See also: – |

Compiled in Program Version 5.10. Help data last modified 12 Oct 2001 22:28:00.00. Class wCplWoKitto last modified 23 Sep 2017 10:50:49.