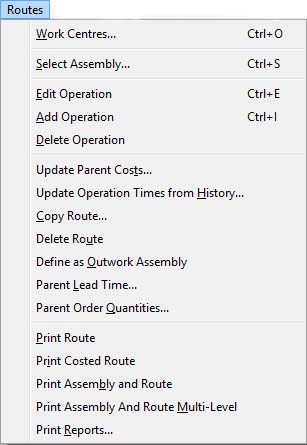

– Process Routes Menu

Process Routes contain one or more manufacturing operations that are carried out on the components of the BoM to produce the completed Parent assembly. The process route file contains a list of all operations and details on the work to be carried out in processing the kit of parts into the completed parent.

Process routes can exist for parts that have no BoM, however, they should be ‘M’ake type parts for the costs of operations to be accounted for.

Outwork operations which are those carried out in outwork work centres, can be purchased in the Purchase Order system.

The Process Routes menu provides for maintenance of Process Route operations. Process Routes are lists of operations carried out in Work Centres in the factory to convert a BoM kit of parts into its parent assembly.

|

Line |

Function |

Keys |

|---|---|---|

|

Work Centres |

To view and maintain the list of Work Centres. Work Centres are the operational stations in the factory. This function opens the Work Centre Maintenance window. |

Ctrl+O |

|

Select Assembly |

To select a parent part to show or create operations for it. This function opens and operates on the Process Route Maintenance window. You will be asked to select a parent part in the Part Selection window. |

Ctrl+S |

|

Edit Operation |

To edit the details in the currently selected operation. This has the same effect as double-clicking on an operation list line. This function opens and operates on the Process Route Maintenance window. |

Ctrl+E |

|

Add Operation |

To add an operation to the process route. This function opens and operates on the Process Route Maintenance window. |

Ctrl+I |

|

Delete Operation |

To delete the Operation that is currently selected on the operation list. This function opens and operates on the Process Route Maintenance window. |

|

|

Update Parent Costs |

To review a single-level cost analysis for the assembly. The analysis is used in normal product costing without recalculating lower sub-assemblies. You can update both part current costs and pricing if your privileges permit. This function opens and operates on the Process Route Maintenance window. It opens the Part Costs Update window for the selected parent. |

|

|

Update Operation Times from History |

This function allows you to update process route operation times from work history records for assemblies choson from the Parts ScratchPad. It opens the Process Times Update window. |

|

|

Copy Route |

To duplicate the currently selected route to an alternate parent part. The part entered must be pre-defined in the parts master but does not have to have the same BoM. This function opens and operates on the Process Route Maintenance window. |

|

|

Delete Route |

To delete all operations for the currently selected parent part. This function opens and operates on the Process Route Maintenance window. |

|

|

Define as Outwork Assembly |

To redefine the parent Part Type as an Outwork assembly. When a parent is an outwork assembly it does not make use of a process route. This function opens and operates on the Process Route Maintenance window. |

|

|

Parent Lead Time |

To change the parent part lead time based on an accumulation of the operation times and Work Centre available hours. Calculations assume infinite capacity. This function opens and operates on the Process Route Maintenance window. It opens the Parent Lead Time Adjustment window for the selected parent. |

|

|

Parent Order Quantities |

To change the parent Minimum Order Quantity and Lot Size based on operation times and Work Centre cost rates. This function opens and operates on the Process Route Maintenance window. It opens the Parent Minimum Order and Lot Size Adjustment window for the selected parent. |

|

|

Print Route |

To print operation details for the currently selected parent. This function opens and operates on the Process Route Maintenance window. |

|

|

Print Costed Route |

To print a costed analysis of the Process Route currently selected. This function opens and operates on the Process Route Maintenance window. |

|

|

Print Assembly and Route |

To print the currently selected assembly and any process route that exists. This function opens and operates on the Process Route Maintenance window. |

|

|

Print Assembly And Route Multi-Level |

To print the currently selected assembly and any process route that exists and any sub-assemblies with their routes. This function opens and operates on the Process Route Maintenance window. |

|

|

Print Reports |

Provides reports based on the Process Route operations. This function opens the Process Route Reports window with the Process Route Operation Selection subwindow. |

|

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:48:00.00. Class mRoute last modified 18 Apr 2012 12:39:45.