OVERVIEW

To set up capacity planning you must first set up your process routes. Process operations make up process routes and there should be one process route for each non-phantom assembly. A single end part may have several process routes as it makes its way through as many different work centres as required.

File Path

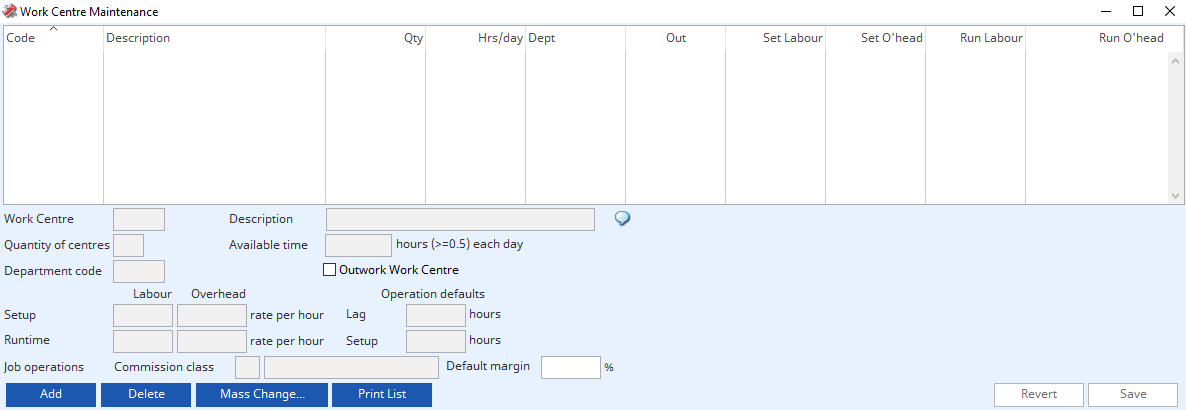

Masters > Process Routes > Work Centres

This file path will take you to the Work Centre Maintenance window.

Add button

Selecting this button will allow you to set up a new work centre and will highlight the next available line in the work centre field at the top of the screen.

Work Centre

Insert the name of the work centre here. This can be up to three characters in length eg. WST or QTY.

Description

Enter the name of the workstation in this field eg. Workstation or Quality Control.

Quantity of Centres

The amount of this type of work centre goes here. Eg. You may have 3 Workstations but only one Quality Control area available.

Available time

How much available time is allocated per day to each workstation.

TIP: Having 2 work centres, each with 8 hours per day, is not the same as having 1 work centre working 16 hours a day. A Work Order batch can only pass through one Work Centre. An 8-hour operation will take a full day in the first case whereas it will take a half day in the latter case. In this way you can identify work centres that can operate operations in parallel or series.

Department Code

You may have several work centres allocated to the same department code eg. Workstation and paint may all come under assembly, and you may want to use the code ASSY.

Outwork Work Centre

Tick this box if this is an outwork work centre.

Setup Labour

Enter the setup labour rate per hour for the workstation here.

Setup Overhead

Enter the setup overhead rate per hour in this field.

Runtime Labour

The runtime labour rate is entered here.

Runtime Overhead

The runtime overhead hourly rate is entered here.

Operation defaults

Lag

The lag time in hours is entered here.

Setup

The setup time in hours is entered in this field.

Commission Class

The commission class for this workstation can be entered in this box as appropriate.

Default Margin

The default commission margin is entered here.

BUTTONS AND FIELDS

Work Centre List

In this field you will see a list of all your work centres. To amend work centre details, highlight the appropriate line on this list. The data for this Work Centre can now be changed.

Work Centre Code

This is your unique identifier code for your work centre.

Description

This is the description of your work centre.

Available Time

Hours available in each Make Day for the work centre.

Department Code

This is used to group work centres. You can use this as a way to group departments and view capacity analysis by department rather than specific work centres.

Outwork Work Centre

This box would be ticked if you wish this work centre to be designated as an outwork centre.

If you designate a Work Centre as an Outwork work centre, operations assigned to it are assumed to be processed by an outside sub-contractor. These operations must be purchased on a Purchase Order and then received in the normal PO manner before further normal operations can be processed.

NOTE – Care should be taken with applying cost rates to Outwork work centres. It is recommended that you apply a single unit of cost (1.00, or 10.00 or 100.00) to both setup and run labour rates, with zero overhead rates. Then use setup and run times to determine costs.

Setup Labour Rate

This is the set-up labour cost per hour.

Setup Overhead Rate

In this field you can enter the setup overhead cost per hour. This should include normal overheads attributable to the Work Centre as well as any special set-up consumables not provided for in the Bill of Materials.

Runtime Labour Rate

This is the runtime labour rate per hour for the selected workstation eg. If you have 2 people working at that station each on £10 per hour, the runtime labour rate per hour will be £20.

Runtime Overhead Rate

The runtime overhead cost per hour is entered here. This should include normal overheads attributable to the Work Centre as well as any special time based consumables not provided for in the Bill of Materials.

Default Operation Lag Time

The default operation lag time for process route maintenance is entered in this box.

Default Operation Setup Time

You can enter any default operation setup time for process route maintenance here.

Job Operation Commission Class

Enter any appropriate commission class previously set up in the Commissioned Sales Agents Maintenance window.

WARNING: If a blank commission class is applied, no commission agents will be filtered onto job lines.

Default Margin

Enter the default margin to be applied to job operations for the commission class.

Add Button

Selecting this button will create a new (normally blank) record in the file ready for you to enter details for the record.

Delete Button

If you select this button, you will permanently remove the currently selected record from the file. You will be asked to confirm you wish to delete the highlighted work centre. You can confirm with a yes or abandon the deletion with a no.

Mass Change Button

To mass change one work centre for another for a range of parts. This is particularly useful when you want to delete an obsolete work centre. It opens the Work Centre Mass Change window.

Print List Button

This button will cause a report to be printed of the subject matter.

Revert to Saved Button

This will cancel any changes and revert to the last saved record.

Save Changes Button

Selecting this button will save any changes you have made.

Compiled in Program Version 6.00. Help date last modified on 7 July 2021

Class wWkcEdit (Work Centre Maintenance) FP: Masters > Process Routes > Work Centres