OVERVIEW

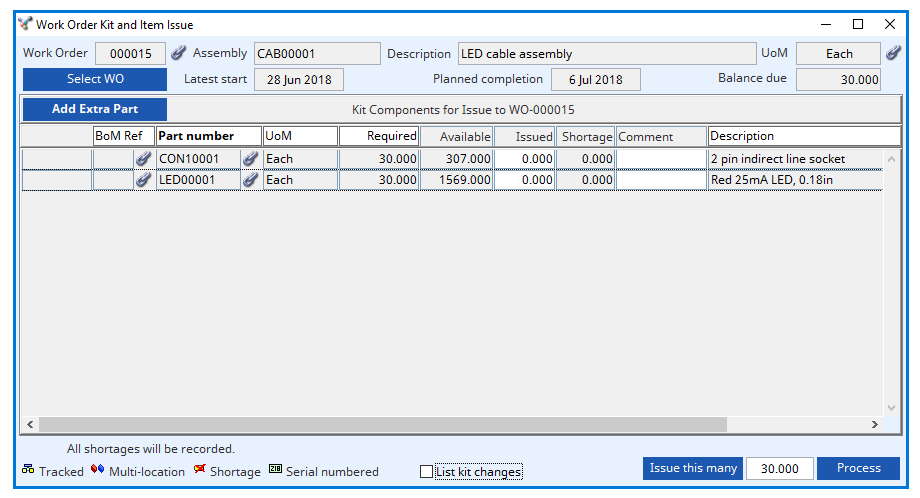

When a Non-Backflushed Work Order is created, it has its non-bulk components allocated. Just before production the kit of components must be issued. During this process the allocations are removed, stock issued and placed in kitted work-in-process. Kits can also be returned, reversing this process. This window is used for both Issues and Returns. You gain access by operating the Process — Work Orders — Issue Kit or Items to WO or Return Kit Items from WO menu functions.

You will be first asked to select a Work Order in the Select Work Order window.

Kit Issue

The system will build a list of all components needed using the Bills of Material file. No Bulk issue or non-stock parts will be included and Phantom assemblies will be exploded. The list presented will show the required quantities for the entire order quantity. If an issue has already been made, only shortages will be shown. If nothing is listed, you can continue in any event to issue Extra Items.

A quantity in the Shortage column indicates that a Shortage will be recorded. If no WO Kitting Variance is set in File — System Manager — Company Details, any discrepancy from the kitted quantity required by the Bill of Materials will be recorded as a shortage. If you set a WO Kitting Variance, and then enter a kitted quantity unequal to the BoM Required quantity but within the Variance range, you will be given the option of recording a shortage or not.

This can be useful where minor variance in kits occur. However, care should be taken, particularly when the kit is returned. The system does not save the kitted bill with the Work Order. Whenever transactions take place, the current BoM is used to determine quantities. Hence, you will find that component parts Kitted in WIP quantities are for the full BoM quantity when shortages are not recorded. When a kit return takes place the system will not take account of variances and any variance on return must be accommodated by manual stock adjustments.

You must enter the quantities kitted for each listed item into the list before confirming the issue.

Clicking on the Issue this many button will automatically set the kitted values to the quantity appropriate to the assembly quantity entered, up to the Available Quantity. Individually enter the grid cell to change an issued quantity.

Any items where the kitted quantity is less than the required quantity will be automatically recorded as Shortage items, regardless of any current stock physical quantities. You will be warned that Shortages will be created at the time of confirmation of the issue.

When satisfied with the data entered on the list, click on the Process button.

Parts that are flagged as Multi-location or Tracked are indicated as such in the list. You will be presented automatically with the Location/Batch assignment dialog.

If component parts have been given the Allow auto-selection of location attribute, the system will attempt to pre-select the locations. It will also abide by the Draw from several locations attribute and follow the Assembly auto-selection preferred location prefix, if any, on the Work Order assembly part record. Any auto-selections will be shown, and you must confirm them before processing can be carried out.

After confirmation, the system makes all stock adjustments and creates inventory history records and shortage records. Only one kitting process is permitted for each Work Order. The processing alters the following files:

Work Order record kit issue date is date-stamped and cost elements of all components, including Bulk Issue items, are calculated, and added to the Work Order cost fields.

Component part records are adjusted to reflect the reduction in Physical quantity and Allocated to WOs and the increase in Kitted in WIP.

Stock location records, where relevant, are adjusted or deleted if the resultant quantity is zero.

Tracking records, where relevant, are created.

Stock History records are created if System Preferences are so set.

After the issue, additional parts needed for the Work Order must be issued as shortage items, if shortages, or as extra items. This is done using the same window and menu function.

Kit Return

The Kit Return feature is provided to enable the return of items of a kit issued to a Non-Backflushed Work Order. Care must be taken with this function. In normal Operation, it’s use should be restricted to the return of all balance kit items on the Work Order. This is useful in the event of a decision to cancel a Work Order after kit issue and partial or full abandonment of assembly production. The return of ALL balance items must precede the cancellation or amendment of a Work Order. Because at each stage of processing a Work Order, the current Bill of Materials is used, a return of the kit before changing the Bill of Materials is necessary to retain data integrity. After changing the Bill of Materials, the Work Order kit can be re-issued with the new part quantities. Processing of the return is similar to the kit issue.

After selection of an issued work order, the system will build a list of all components issued using the Bills of Material file and remove any items in the shortages file that are still awaiting issue.

If you use the Full Return button to populate the list with the full kit, the work order kit will be assumed fully returned and the kitted date blanked. If after clicking on the button you change some returned quantities, any balance of the component will be assumed to have been scrapped.

If you DO NOT use the Full Return button and populate the list manually, maybe for only some of an item, the work order kit will remain kitted. The quantity returned will then be added to the order shortages.

File Path

Process > Work Orders > Issue Kit or Items to WO…

This file path takes you to the Work Order Kit and Item Issue window.

Work Order

Work order number. {WKOFILE.WKOWONO char 6}

Assembly

Part number (parent assembly). {WKOFILE.WKOPTNO char 18}

Description

Part description. {PTMFILE.PTMDESC char 30}

UoM

Standard stock unit of measure. {PTMFILE.PTMSTUM char 6}

Link icon

Click to view any linked external files. Hold the shift key down and click to create a new file link for the record.

Select WO button

To select a specific Work Order. It opens the Select Work Order window.

Latest start

Latest kitting and start date. {WKOFILE.WKOLATE date date1980}

Planned completion

Date of planned completion. {WKOFILE.WKOCDAT date date1980}

Balance due

Balance due still for completion. {WKOFILE.WKOBAL number 3dp}

Add Extra Part button

To use a part selection dialogue to add an extra item to the component list of issued work order. Alternatively, you can drag and drop from the Parts ScratchPad or BoM Listing. (This button is not visible when processing a kit return.)

Kit Components for Issue to WO-… grid

A list of component parts to issue or return. Sorting the list will reset all editable values to the default.

BoM Ref

Component reference within structure. {BOMFILE.BOMCREF char 4}

Part number

Component part number. {BOMFILE.BOMCPNO char 18}

UoM

Standard stock unit of measure. {PTMFILE.PTMSTUM char 6}

Required

The kit quantity required for issue or available for return.

Available

The available stock. Calculated from the current part physical less any other issues. With multiple entries of the same part, this will change depending on the sort order.

Issued

The quantity being issued or returned.

Shortage

The quantity being issued or returned.

Comment

The inventory comment that will be used when recording the part movement.

Description

Part description. {PTMFILE.PTMDESC char 30}

Clear requirements

Ticking this box will clear the requirement for the listed item.

List kit changes

With this box checked, once processed, a printable alert message will open with a detailed list of all changes that have been made when issuing the kit to the works order. This list will only appear if a change has been made.

List kit changes

With this box checked, once you have issued the kit to the works order, the Received Work Order Assemblies from Production window automatically opens with the work order data already pre-loaded.

Issue this many button

To issue the parent quantity entered of items to the extent that the available permits. (This button is not visible when processing a kit return.)

Full Return button

To return all items in full. (This button is not visible when processing a kit issue.)

Process button

To process the Issue or Return

See also: |

|

Compiled in Program Version 5.10. Help data last modified 28 June 2022.

Class wWoKitIssue last modified 25 May 2022.