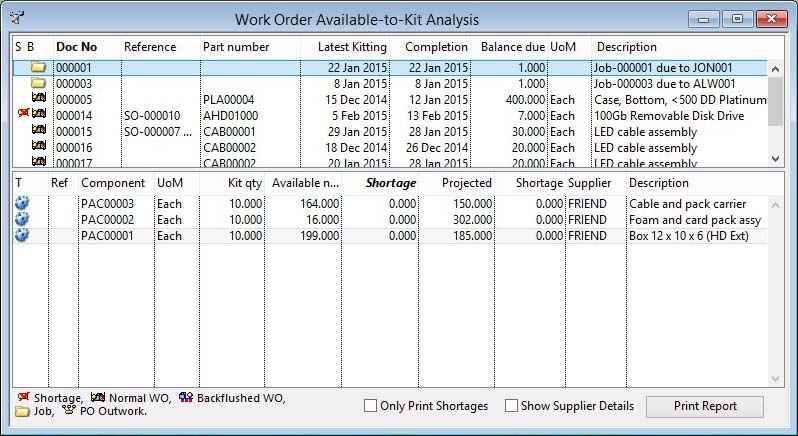

Work Order Available-to-Kit Analysis

This window provides the analysis results of the Process — Work Orders — Review WOs Available-to-Kit menu function.

It provides for a more comprehensive listing than the kit stock status review. The system prepares a full listing of the component needs of ALL un-kitted WO’s (and Jobs and PO outwork assemblies if those option are chosen). It does this in the order of Latest start date and forward plans the component and material inventory levels, based on the current physical stock.

You have a choice of a number of options which are made in the Work Order Available-to-Kit Options window.

The Required quantity is drawn from the respective assembly’s Bills of Material.

The Available and Projected with associated Shortages are calculated through the lists in the order they are sorted on the window.

Initially, the predicted Available quantity is the part’s Physical quantity. If the part is required in more than one Work Order, the quantities will follow through so that the Available quantity for the later requirement is drawn from the resultant quantity of the part’s earlier requirement. And so on through all instances of the component part.

The Projected quantity is the quantity that should be available for the items kit issue at the end of all predicted stock movements. This is similar to the normal part’s Projected stock quantity as seen on the Part’s Current Quantity subwindow, but calculated prior to this specific kitting requirement, for a non-backflushed order. The Projected shortage is then computed accordingly.

To illustrate the treatment of common components imagine a scenario where you only have 2 work orders for the same assembly which has a single component part. That component has a Physical quantity of 2 in stock and Projected of 0, as 2 are allocated to the 2 work orders. In the Available-To-Kit the two entries of the component would be:

First line: Required = 1, Available = 2, Shortage = 0, Projected = 1, Projected Shortage = 0

Next line: Required = 1, Available = 1, Shortage = 0, Projected = 1, Projected Shortage = 0

Work Orders are listed on the upper list and the selected order’s kit is shown in the list below .

![]() WARNING: No account is taken of inventory subject to Sales Order or Job outgoings or Work Order and Purchase Order incoming stock. MRP is the only mechanism of analysis and forecasting that accounts for all demands on, and supply to, inventory.

WARNING: No account is taken of inventory subject to Sales Order or Job outgoings or Work Order and Purchase Order incoming stock. MRP is the only mechanism of analysis and forecasting that accounts for all demands on, and supply to, inventory.

|

Field |

Description |

|---|---|

|

Work Order List |

Work Orders for kitting as selected. Click on one to view its trial kit. Shortages will be recalculated if the list is sorted. |

|

Kit List |

List of kit for the Work Order that will require issue. Work Orders with no component listed indicates that the WO assembly has no bill of materials defined for it. |

|

Only Print Shortages |

If checked, only those kit items showing a shortage will be printed. |

|

Show Supplier Details |

If checked, Supplier contact details will be additionally printed. This option looks at the data in the same manner as the listing, however it looks also at outstanding Purchase Orders for the components and lists details of them so that you can see when supplies are expected to fulfil any shortages that may exist. |

|

Button |

Action |

|---|---|

|

Print Report |

To print a report of the available-to-kit analysis listing with options. Right-click to change the report destination. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 29 Aug 2012 07:50:00.00. Class wWkoAvailable last modified 23 Sep 2017 10:51:13.