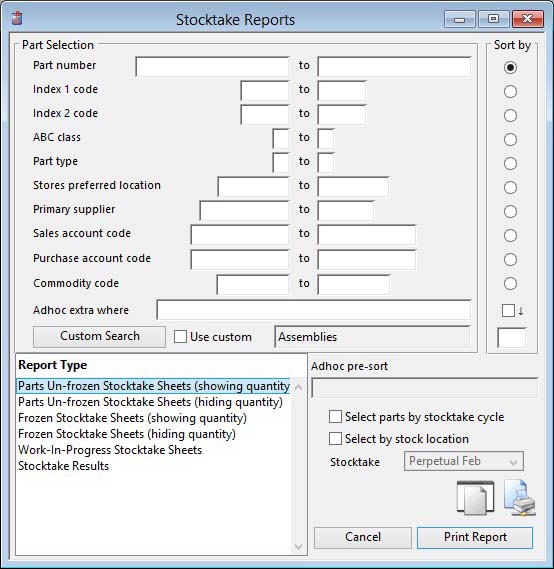

Stocktake Reports

This report setup window provides you with the ability to choose a range of selections, sort order and report types. It also forms the basis of the Stocktake Freeze window.

You can drag and drop onto the Print Report button from the Parts Scratchpad to obtain a report (or stocktake freeze) of selected parts only.

![]() NOTE: This window contains fields introduced with version 5 that enable additional search (and sometimes sort controls), such as Adhoc extra where. For more help on their use and examples see the Client-Server SQL Introduction help.

NOTE: This window contains fields introduced with version 5 that enable additional search (and sometimes sort controls), such as Adhoc extra where. For more help on their use and examples see the Client-Server SQL Introduction help.

|

Field |

Description |

|---|---|

|

Part Selection |

Enter a selection in the Parts Selection subwindow. |

|

Sort option |

Choose the field for the primary sort of parts on the report. |

|

Report Types |

Select a report type. Any custom reports entered in the Settings will appear at the bottom of the list. Some field states on the window will change depending on the type of report selected. |

|

Select parts by stocktake cycle |

Check to select all parts due to be stocktaked by cycle days. |

|

Select by stock location |

When selecting a restrictive range of Store Primary Location, choose this option to have the range apply to multi-stock locations rather than part primary location. |

|

Button |

Action |

|---|---|

|

Stocktake drop-down list |

Select from this list the stocktake you wish to report on. |

|

View Details |

Click to view the details of the selected stocktake. |

|

Cancel |

Aborts the process currently in session. The keyboard equivalent is the Esc key for Windows computers and Command-.(full stop or period) for the Mac. |

|

Print Report |

Will cause a report to be printed of the subject matter. Right-click to change the report destination. |

Work-in-process kitted items checksheets

This Report Type is not connected with freezing or frozen stock. It provides a report that lists all parts kitted to Work Orders. This is provided for auditing purposes.

The listing includes Bill of Material kit quantities for the Work Order balance due less any Shortages recorded. Kits are assumed to be located as a single batch at the Work Centre of the operation following the last logged work history, or the first operation if there is no history, or the final operation if all have logged history. Backflushed and un-kitted Work Orders are not included. Bulk Issue items are not included in kits.

| See also: – |

Compiled in Program Version 5.10. Help data last modified 3 Jan 2015 10:45:00.00. Class wSttPrint last modified 17 Oct 2017 04:29:57.