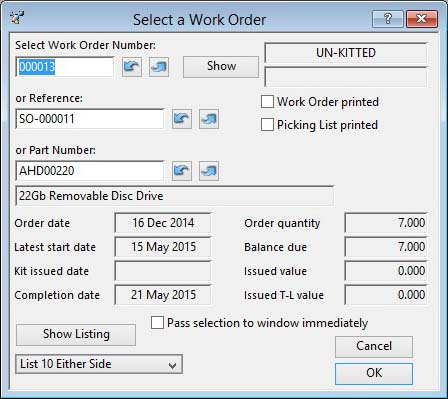

Select Work Order

This window enables you to select an existing Work Order.

You can enter a WO number, Reference or Assembly Part Number to find the desired document. When passing out of each of the fields the system will find the closest matching WO record to the data entered. You can click on the Show Listing button to build a list of all WOs in the system controlled by the selection you make in the dropdown list below the button. You can also use the Show button to view the Work Order Details window.

|

Field |

Description |

|---|---|

|

Work Order Number |

Work Orders. Work order number. {WKOFILE.WKOWONO char 6} |

|

Reference |

Work Orders. User reference for WO. {WKOFILE.WKOUSER char 15} |

|

Assembly Part Number |

Work Orders. Part number (parent assembly). {WKOFILE.WKOPTNO char 18} |

|

Description |

Parts Master. Part description. {PTMFILE.PTMDESC char 30} |

|

Kit Issued |

Work Orders. Kit issued date. {WKOFILE.WKOISDT date date1980} |

|

Backflushed |

Work Orders. To be backflushed flag. {WKOFILE.WKOBACK boolean} |

|

Work Order printed |

Work Orders. WO Printed flag. {WKOFILE.WKOPRNT boolean} |

|

Picking List printed |

Work Orders. Picking List Printed flag. {WKOFILE.WKOPLPR boolean} |

|

Order Date |

Work Orders. Ordered date. {WKOFILE.WKOODAT date date1980} |

|

Order Quantity |

Work Orders. Quantity ordered. {WKOFILE.WKOOQTY number 3dp} |

|

Latest Start Date |

Work Orders. Latest kitting and start date. {WKOFILE.WKOLATE date date1980} |

|

Balance Due |

Work Orders. Balance due still for completion. {WKOFILE.WKOBAL number 3dp} |

|

Kit Issued Date |

Work Orders. Kit issued date. {WKOFILE.WKOISDT date date1980} |

|

Issued Cost Value |

The current costs of materials issued so far to the Work Order, less any passed into history by recorded work operations.

|

|

Completion Date |

Work Orders. Date of planned completion. {WKOFILE.WKOCDAT date date1980} |

|

Issued This-Level Value |

Work Orders. Current accumulated this-level cost of components. {WKOFILE.WKOCTLC number 3dp} |

|

Pass selection to window immediately |

Check to cause the selection to be immediately reflected on the target window. |

|

Button |

Action |

|---|---|

|

Show |

Click to open the Work Order Details window. |

|

Show Listing |

Click to show a list of orders based on the selection below. It opens the Work Order List window. |

|

List Contents Dropdown List |

Choose a selection for the listing. |

|

Cancel |

Aborts the process currently in session. The keyboard equivalent is the Esc key for Windows computers and Command-.(full stop or period) for the Mac. |

|

OK |

The OK button updates the data you have entered, or confirms the selection and/or processes the function you have called. |

|

|

Will cause a report to be printed of the subject matter. Right-click to change the report destination. |

Printing Documents

![]() TIP: The Bill of Material structure comment texts can be used to hold instructions for the Stockman, such as material cutting instructions, handling warnings, pre-production preparation requirements, etc..

TIP: The Bill of Material structure comment texts can be used to hold instructions for the Stockman, such as material cutting instructions, handling warnings, pre-production preparation requirements, etc..

![]() NOTE: The Do not consolidate common BoM components on kit lists System Preferences control can be set to prevent consolidation of common components in a BoM so that BoM References and Structure comment is fully printed on the kit list.

NOTE: The Do not consolidate common BoM components on kit lists System Preferences control can be set to prevent consolidation of common components in a BoM so that BoM References and Structure comment is fully printed on the kit list.

Print Work Order

When a Work Order is printed, the following data is included on the document:

- Work Order information.

- The assembly part’s extra works individual and standard texts.

- Engineering Data for the assembly part if referenced in the work extra text.

- Process Route Operation details for the assembly.

- If the Work Order control is set, a list of Kit Components, including Bulk Issue parts.

- If Phantom assemblies are present in the kit, they will be exploded on a multi-level basis.

- If the BoM structure comment shown on WO component list System Preferences control is set Bill of Materials structure comment will be included within the Kit list.

![]() CUSTOM CAPABILITY: The Work Order design can be customised to reflect your local needs. The standard report format is named rWorkOrder. There is an alternative standard design with barcodes to suit Work Tracking named rWorkOrderB. There is also an alternative standard design with the kit before the route and a QA Testing listing at the end to suit the process industry named rWorkOrderQA. Either can be duplicated and modified in the OpenVision library. To provide for them being offered to users as alternatives each class must be entered as type WO custom reports in your settings.

CUSTOM CAPABILITY: The Work Order design can be customised to reflect your local needs. The standard report format is named rWorkOrder. There is an alternative standard design with barcodes to suit Work Tracking named rWorkOrderB. There is also an alternative standard design with the kit before the route and a QA Testing listing at the end to suit the process industry named rWorkOrderQA. Either can be duplicated and modified in the OpenVision library. To provide for them being offered to users as alternatives each class must be entered as type WO custom reports in your settings.

![]() NOTE: You may choose to have the Kit List, when shown on the Work Order document, sorted by Bill of Materials reference value then part number rather than simply by part number. This can be achieved by setting the option optWOKitSort to 1 or YES.

NOTE: You may choose to have the Kit List, when shown on the Work Order document, sorted by Bill of Materials reference value then part number rather than simply by part number. This can be achieved by setting the option optWOKitSort to 1 or YES.

![]() TIP: Normally an WO is marked as printed only if it is printed directly to a Printer or Email. It will not be marked as printed if it is sent to the Screen or Preview and from there on to the Printer. You can override this behaviour such that it will be marked as printed regardless of the destination by setting the Option optWOPrintMarkAll to 1. You can generally override the Printer and Email default destinations with the optRepDestMarkDoc option that allows you to set a selection of destinations for which documents will be marked as printed.

TIP: Normally an WO is marked as printed only if it is printed directly to a Printer or Email. It will not be marked as printed if it is sent to the Screen or Preview and from there on to the Printer. You can override this behaviour such that it will be marked as printed regardless of the destination by setting the Option optWOPrintMarkAll to 1. You can generally override the Printer and Email default destinations with the optRepDestMarkDoc option that allows you to set a selection of destinations for which documents will be marked as printed.

Print Work Order Kit Picking List

This function prepares a stockman pick document for a selected Work Order. The Picking List document is prepared using the following rules:

- Work Order comments are included on the heading.

- Assembly part extra works individual and standard texts are included on the heading.

- The current Bill of Materials is used to construct the list.

- It will NOT include any components that are N-type Non-stock or Bulk Issue parts.

- Components that are P-type Phantom assemblies are exploded through all levels.

- Duplicate entries of parts are consolidated into one entry unless they are Batch Tracked parts.

- The final listing is printed in Preferred Location order.

- Any Bill of Material structure individual comment and standard text is included.

- For Multi-location parts an extra entry box is printed to identify the location/batch source of the picked quantity.

![]() NOTE: You may choose to have the Work Order Picking List sorted by Bill of Materials reference value rather than by stores location and then part number. This can be achieved by setting the option optWOPickSort to 1 or YES. This can add a further element to your stores picking policy.

NOTE: You may choose to have the Work Order Picking List sorted by Bill of Materials reference value rather than by stores location and then part number. This can be achieved by setting the option optWOPickSort to 1 or YES. This can add a further element to your stores picking policy.

![]() TIP: Normally an WO is marked as having the picking list printed only if it is printed directly to a Printer or Email. It will not be marked as printed if it is sent to the Screen or Preview and from there on to the Printer. You can override this behaviour such that it will be marked as printed regardless of the destination by setting the Option optWOPickPrintMarkAll to 1. You can generally override the Printer and Email default destinations with the optRepDestMarkDoc option that allows you to set a selection of destinations for which documents will be marked as printed.

TIP: Normally an WO is marked as having the picking list printed only if it is printed directly to a Printer or Email. It will not be marked as printed if it is sent to the Screen or Preview and from there on to the Printer. You can override this behaviour such that it will be marked as printed regardless of the destination by setting the Option optWOPickPrintMarkAll to 1. You can generally override the Printer and Email default destinations with the optRepDestMarkDoc option that allows you to set a selection of destinations for which documents will be marked as printed.

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:49:00.00. Class wWorkOrderno last modified 17 Oct 2017 04:29:57.