Stocktake Freeze

Inventory Stocktake can be handled in two ways:

- You can simply produce a report for Stocktake purposes and after the count, use Stock Control Adjustment to update the part physical quantity. However, this procedure would involve the following, to ensure an accurate result: Firstly, the stock must be physically secured (no parts in or out), then all stock transactions on the system must be brought up-to-date, then print the stocktake sheets and from then on make no further transactions on the computer system until the count is over and the results have been entered. In most environments this can cause substantial inconvenience to the normal running of the business.

- Alternatively, you can prepare a Stocktake list at the same time as freezing the computer records of physical stock. Using this technique, the only requirements for accuracy is that computer transactions for stock are up-to-date and that the stock subject to stocktake remains physically unchanged during the counting process. During the counting process, transactions on the computer can continue and there is no need to enter the count results immediately. In effect the moment a part is counted, it can be released for normal movements. The only important thing to ensure is that physical stock is not changed between ‘freeze’ and count. When the count results are entered the user works only with the quantity frozen at the time of stocktake. This procedure is particularly useful for random, partial or continuous stocktaking.

![]() NOTE: Make sure your part costs are up to date at the time you freeze stock. The frozen stock records hold the total current and standard cost of each part at the time the stock was frozen. After you have entered the results of the stocktake, you will be in a position to directly relate the value of amendments to stock quantity to the stock value at the time they were frozen.

NOTE: Make sure your part costs are up to date at the time you freeze stock. The frozen stock records hold the total current and standard cost of each part at the time the stock was frozen. After you have entered the results of the stocktake, you will be in a position to directly relate the value of amendments to stock quantity to the stock value at the time they were frozen.

The system allows you to have any number of open frozen stocktake sets, each of which you need to identify with a name. This enables you to run a number of partial stocktakes concurrently covering different major locations or part classes.

Frozen stocktake sets remain permanently on file, even after all results have been entered, until they are deliberately removed using the Datafile Integrity Maintenance window Archive and Delete pane Delete Closed Stocktake Results button function.

Stocktake Freeze Process

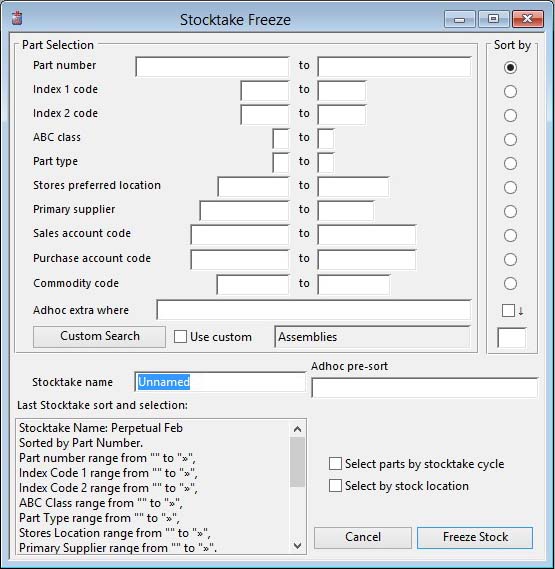

This window is used to select a range of parts to freeze for a stocktake. The window is a variant of the Stocktake Reports window to which you are referred for more detailed information.

In the scrollable box at the bottom left will be the details of the last stocktake selection and other details. This is provided as an aide-memoir for routine continuous stocktaking.

To freeze a stocktake, you must select the range of parts subject to the stocktake. You can also use the Keyword or Parts Scratchpad to transfer a selection of parts, or use drag and drop from the Parts ScratchPad. When the user confirms the selection the physical quantities and multi-locations of all parts matching the selection are stored in a frozen quantity file. When the records are created the Stocktake checksheets can be printed from the Stocktake Reports window.

The Select parts by stocktake cycle option disables all other selection options and produces a freeze set of all parts due for stocktake based on the Last stocktake date and Cycle days values for each part. This provides for a comprehensive cycle counting policy.

|

Field |

Description |

|---|---|

|

Stocktake name |

Enter a unique name for this Stocktake Freeze. |

|

Last Stocktake sort and selection |

Company and System Settings. Stocktake freeze selection criteria. {MCDFILE.MCDSTTC char 2000} |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:48:00.00. Class wSttFreeze last modified 4 Apr 2018 08:06:40.