Sales Order Line Item Maintenance

This detailed subwindow forms part of the Sales Order Maintenance window.

|

Field |

Description |

|---|---|

|

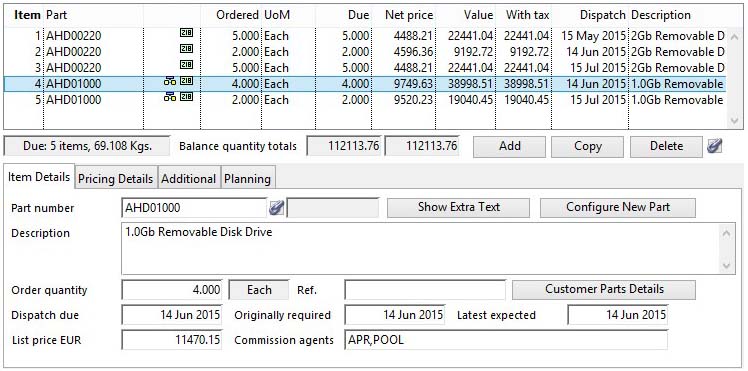

Line Item List |

All line items will be listed for the Sales Order that have not been fully dispatched. Click on a line item to show and edit the full details.

|

|

Lines and Weight |

The number of Sales Order line items due for dispatch and the total of part item mass this represents. |

|

Balance Total Without Tax |

The total value for all outstanding items on the Sales Order, inclusive of discount but exclusive of tax. |

|

Balance Total with Tax |

The total value for all outstanding items on the Sales Order, inclusive of discount and tax. |

|

Button |

Action |

|---|---|

|

Add |

This will create a new (normally blank) record in the file. You will then be able to enter details for the record. Then confirm with an OK, or abandon the New record with a Cancel. You will be warned if a CBD Invoice has been prepared for the SO as any changes will cause inconsistencies between what your customer expects to pay and what you will expect to receive. When entering an order item the following rules apply:

|

|

Copy |

This will create a Copy of the current record displayed on the window. You will then be able to change the details. Confirm with an OK, or abandon the new record with a Cancel. |

|

Delete |

Execute this button to permanently remove the currently selected record from the file. If you are permitted to delete the item, you will be asked for confirmation, otherwise an explanation will be given. |

The window has 4 tab panes.

Item Details

Pricing Details

Additional

Planning

Item Details

This pane shows the essential base details for the selected order line item.

|

Field |

Description |

|---|---|

|

Line Item Number |

The line item number, from 1 to 999, is automatically generated for each sales item, a deleted line number is not re-used unless there are no higher line item numbers. |

|

Part Number |

Sales Order Line Items. Part number. {SOLFILE.SOLPTNO char 18} The part number on order which must be a pre-defined part in the Parts section, or blank if not an inventory part. N type non-stock parts can be used, and are useful for standard delivery charges, services, etc.; no part quantities are affected or stock history made for non-stock parts. A partial part number can be entered, whereupon the nearest matching part record is located by the system. The ScratchPad can be used to drag and drop a selection of parts onto the Line Item List.

|

|

Part Type |

Parts Master. Part type (A,B,M,N,O,P). {PTMFILE.PTMTYPE char 1} |

|

Description |

Sales Order Line Items. Item description. {SOLFILE.SOLDESC char 32000} If a valid part number is added the part description is provided here. It can be edited if needed. The description field must be used for non-part items such as services.

|

|

Order Quantity |

Sales Order Line Items. Quantity in Sales UoM. {SOLFILE.SOLSQTY number 3dp} Quantity in Sales Units of Measure ordered which defaults to 1.000. If you change the quantity, the Balance due will also change. If you reduce the quantity such that the Balance due becomes zero, the line item will be deleted. There is a System Manager System Preferences setting that controls whether a warning is given if the ordered quantity will result in the projected stock quantity dropping below minimum level were the dispatch be made immediately. If the Warn user during normal SO item entry of low part stock is checked you will receive warnings. The following rules will apply:

|

|

Sales Unit of Measure |

Sales Order Line Items. Sales UoM for the item. {SOLFILE.SOLSAUM char 6} |

|

Item reference |

Sales Order Line Items. Item reference. {SOLFILE.SOLUSER char 15 Idx} Added line items inherit the last code you entered.

|

|

Dispatch Due Date |

Sales Order Line Items. Dispatch date for the quantity. {SOLFILE.SOLDATE date date1980} The date of planned dispatch for the item. If multiple deliveries of an item are planned, multiple item lines with different delivery due dates must be created. For a new Sales Order or Quotation the default date is the next make calendar active date. After entry of one item, default date for further items is that set for the first line item.

|

|

Originally Required Date |

Sales Order Line Items. Customer originally requested receipt date. {SOLFILE.SOLDATO date date1980} |

|

Latest Expected Date |

Sales Order Line Items. Latest expected customer receipt date. {SOLFILE.SOLDATX date date1980} |

|

List Price |

Sales Order Line Items. Price before discount per Sales UoM. {SOLFILE.SOLPRIC number 2dp} The default is the Sales Price from the part’s master record for the part times the Sales UoM Multiplier. It can then be edited. If the order is for a foreign currency, the exchange rate for the SO will be applied. However, if the currency is one of the five sales price currencies set in the File — System Manager — Company Details, and the part has a currency price, this price will then be applied.

|

|

Commission agents |

Sales Order Line Items. Commission agents applicable to this line item (comma separated list of COMIDs). {SOLFILE.SOLCOMA char 100}. The agents applied by default are the agents listed for the customer or additional dispatch address, if applied, filtered by the commission class of the part or non-part class set in company details. The resulting default commission agents comma-separated list can be modified, however on leaving the field the system checks that codes are valid, sorts the list and removes any duplicates.

|

|

Button |

Action |

|---|---|

|

Customer Parts Details |

To open the Customer Parts Maintenance window.

|

|

Show Extra Part Text |

To show the extra texts associated with a part. You will be able to change these texts. This button will, if a part is selected, open the Part Sales Texts window in which the part’s extra sales texts can be viewed and amended. Both individual and standard sales texts are shown. These texts are inserted in the printed Sales Order following the item line for the part.

|

|

Configure a New Part |

To add a line item with a newly configured assembly part. This can only be activated with a saved document. This button only has any function if the Parent Number prefix in SO Configuration has a non-blank value. Sales Item Configuration options are set up in File — System Manager — Sales Item Configuration. Given that you have an appropriate setup in the System Manager section, you can create new assemblies with associated Bills of Material and Process Routes directly using this feature. It will open the Sales Order Item Configuration window and the Select Like-Part for Components Listing window to select a Like-Part for the configuration. |

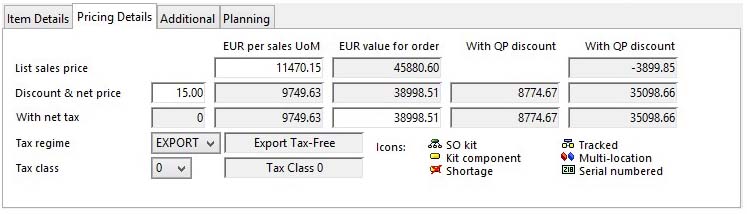

Pricing Details

Pricing details for the selected order line item.

|

Field |

Description |

|---|---|

|

List Sales Price |

Sales Order Line Items. Price before discount per Sales UoM. {SOLFILE.SOLPRIC number 2dp} |

|

List Sales Value |

The total value for the line item quantity, exclusive of discount and tax. |

|

Quick Payment Amount |

Quick payment discount value if applied. |

|

Discount Rate |

Sales Order Line Items. Discount % applied to the item price. {SOLFILE.SOLDISC number 2dpShortnum} The default discount is the customer’s discount rate applying for this part’s discount class. The discount rate can then be edited within a range from 0.00 to 99.99%. |

|

Discounted Price |

The discounted sales price before tax per sales unit of measure. |

|

Discounted Value |

The discounted value for the entire Sales Order line item, exclusive of tax. |

|

Net Price with QP Applied |

The discounted sales price before tax per sales unit of measure and including quick payment discount if applied. |

|

Net Value with QP Applied |

The discounted value for the entire Sales Order line item, exclusive of tax and including quick payment discount if applied. |

|

Sales Tax Class |

Sales Order Line Items. Tax code applicable. {SOLFILE.SOLTAXC integer shortint} The tax rate and amount applicable for this part is automatically calculated from the System Manager control value assigned to the tax class. The tax class can be 0 through 6. A zero class is always zero tax. The default class is drawn from the part’s master record or set to 1 if a non-part item. The default is always zero if there is an Additional Address for the order which has the Zero tax rate default option checked, or where there is no additional address and the Customer has the Zero tax rate default option checked. The tax percent rate is saved with the line item record but can not be edited. It remains in force until invoicing when it is updated to reflect any changes in the “System Manager” settings. This provides for tax rate changes that are always applicable at the date of dispatch and invoice.

|

|

Sales Tax Rate |

Sales Order Line Items. Tax % applied. {SOLFILE.SOLTAX number 2dp} |

|

Discounted Taxed Price |

The sales price per sales unit of measure, inclusive of discount and tax. |

|

Discounted Taxed Value |

The total value for the Sales Order line item, inclusive of discount and tax. |

|

Discounted Taxed Price with QP Applied |

The sales price per sales unit of measure, inclusive of discount and tax and including quick payment discount if applied. |

|

Discounted Taxed Value with QP Applied |

The total value for the Sales Order line item, inclusive of discount and tax and including quick payment discount if applied. |

|

Tax regime and class |

Sales Order Line Items. Tax regime code applicable. {SOLFILE.SOLTAMC char 6} and Tax class applicable. {SOLFILE.SOLTAXC char 1} See the Tax Maintenance window for full details of the tax handling system. The default regime is provided from the customer or the additional dispatch addresses, if applied. The default class comes from the part or default sales non-part setting in the company details. |

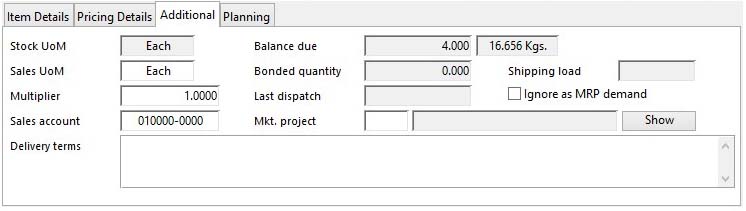

Additional

This pane shows additional details for the selected order line item.

|

Field |

Description |

|---|---|

|

Stock Unit of Measure |

Parts Master. Standard stock unit of measure. {PTMFILE.PTMSTUM char 6} |

|

Sales Unit of Measure |

Sales Order Line Items. Sales UoM for the item. {SOLFILE.SOLSAUM char 6} By default this is obtained from the part’s master record. It can be optionally changed but if the Stock UoM and Sales UoM texts are syntactically the same the multiplier will default to 1.0000. |

|

Multiplier |

Sales Order Line Items. Multiplier of Stock UoM to get Sales UoM. {SOLFILE.SOLMULT number 4dp} By default this is obtained from the part’s master record. It can be optionally changed. |

|

Sales Account |

Sales Order Line Items. G/L sales posting account code. {SOLFILE.SOLACCO char 10} This field is of particular interest when your program license includes the Ledgers option. It provides for a selection of a sales type General Ledger account for the posting of the sale item at the time of dispatch and invoicing. It defaults to the account for the part or the default account for non-part sales. If no account is entered the default part account will be used. If you hold the shift key down when passing out of the account code box, the system will accept a non-Sales type G/L account, otherwise only a ‘S’ type account will be permitted. If you don’t have ledgers, this field can be used for any extra coding needs you may have. |

|

Delivery Terms for Quotation |

Sales Order Line Items. Quotation delivery terms. {SOLFILE.SOLDELI char 300}

|

|

Balance due |

Sales Order Line Items. Balance quantity due in Sales UoM. {SOLFILE.SOLBAL number 3dp} This quantity field is automatically maintained to accommodate multiple dispatches. If you change the order quantity, this value will also change. |

|

Weight |

The mass of the balance due quantity of the selected part item. |

|

Bonded Quantity |

Sales Order Line Items. Bonded quantity in Sales UoM. {SOLFILE.SOLBOND number 3dp} This is a calculated value that shows the quantity of the item placed in bond pending dispatch to the customer. Bonded items are removed from inventory (physical) but not as yet dispatched, and therefore invoiced, to the customer. |

|

Shipping Load |

Sales Order Line Items. Shipping load reference (from MCNLOAD sequence). {SOLFILE.SOLLOAD char 6} This identifies whether the line item has been assigned to a Shipping Load. If blank, it is not assigned. For more details on the Shipping Load system see the Sales Order Shipping Load Assignment window. |

|

Last Dispatch Date |

Sales Order Line Items. Last dispatch date for split deliveries. {SOLFILE.SOLLASD date date1980} This date field is automatically updated when an incomplete dispatch occurs. |

|

Ignore as MRP demand |

Sales Order Line Items. Ignore as MRP demand. {SOLFILE.SOLMRP boolean} A part can be have the Default SO items to be ignored in MRP demand attribute set. This will pass to this SO item attribute when a part is loaded. This characteristic can then the changed in Sales Order line item maintenance. You can use this attribute to eliminate certain products or product groups from control by Materials Requirement Planning. However, you should bear in mind that if the part is an assembly, MRP will not schedule any requirements for it. The consequences of this must be understood in advance as they could be somewhat damaging to your supply situation. |

|

Marketing project code |

Sales Order Line Items. Marketing project code, default from SOHMKTP (IDXID = con(‘0’,SOLMKTP)). {SOLFILE.SOLMKTP char 4 Idx} See the Marketing Data Maintenance window help for more details of Marketing Project codes and their use. |

|

Marketing project description |

Index and Other Codes. Index code, scrap reason, QA test or Incoterm description. {IDXFILE.IDXDESC char 255} |

|

Show |

Lists the available marketing codes set up the File — System Manager — Index Codes. Double-click on a listed code to enter that value. |

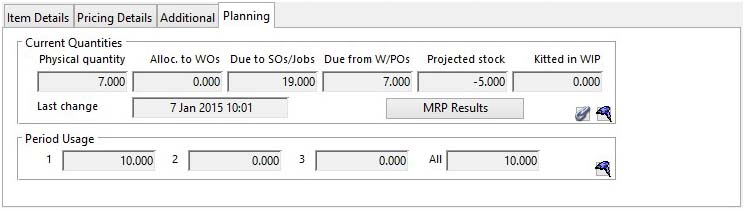

Planning

This pane shows the planning implications of the sale for a part.

|

Field |

Description |

|---|---|

|

Current Quantities |

For details see the Parts Current Quantity subwindow. |

|

Period Usage |

See the Parts Usage subwindow for details. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:49:00.00. Class wSolMaintSub last modified 3 Nov 2017 07:09:32.