Special User Feature – Firm Allocation Analysis

This special user feature is available in open source form in OpenVision.lbs.

This option window, wOptFirmAllocClean, is available to be used as a Custom Feature which will operate along with the use of the optStockFirmAlloc option for firm allocation of multi-location stock on receipt. The allocation option only operates at the time of inward stock movement. This window can be used to identify free stock that is unallocated because it existed when the demand was created and also allocated stock for which there is now no longer any demand. It operates interactively with the Stock Control window and from that (double-click on the Projected quantity) the Part Process Analysis List window. With those windows open, clicking on an analysis list line will refresh the other windows.

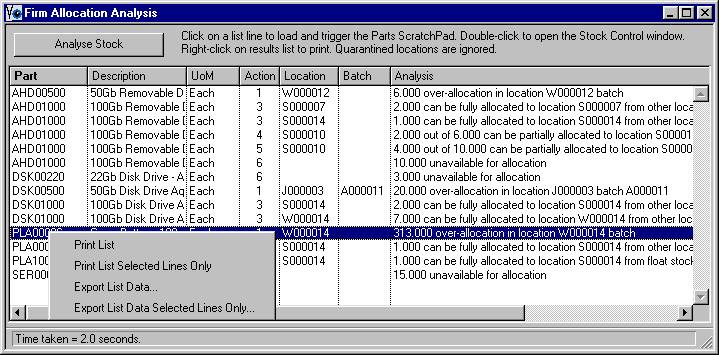

Having performed the analysis: Click on a list line to load and trigger the Parts ScratchPad. Double-click to open the Stock Control window. Right-click on results list to print. Quarantined locations are ignored.

![]() CUSTOM CAPABILITY: This is a customisation class which is provided in open-source form within your OpenVision.lbs library. It may have been originally developed for a specific Caliach Vision user and may be highly specific to their data. It is not covered by normal customer support.

CUSTOM CAPABILITY: This is a customisation class which is provided in open-source form within your OpenVision.lbs library. It may have been originally developed for a specific Caliach Vision user and may be highly specific to their data. It is not covered by normal customer support.

|

Button |

Action |

|---|---|

|

Analyse Stock |

Click to scan all multi-location parts for appropriate firm allocations. |

|

Analyse WO |

Click to analyse multi-location parts in a selected WO kit for appropriate firm allocations. |

|

Analyse PO |

Click to analyse multi-location parts in a selected PO’s outwork kit(s) for appropriate firm allocations. |

|

List |

List of parts with allocation issues that may need attention. Click on a list line to load and trigger the Parts ScratchPad. Double-click to open the Stock Control window. |

The list shows an Action column. This is provided for sorting purposes and to group suggested activities.

|

Number |

Action |

|---|---|

|

1 |

Allocated locations exist for which there is currently no need for the allocation (typically an order has been cancelled) or an excess quantity has been allocated (typically because an order has had its quantity reduced). |

|

2 |

A full allocation can be made from float stock. |

|

3 |

A full allocation can be made from other locations. |

|

4 |

A partial allocation can be made from float stock. |

|

5 |

A partial allocation can be made from other locations. |

|

6 |

There is nothing available to allocate or any available has been suggested for allocation elsewhere. |

Typical Operational Procedure

An appropriate procedure would probably do something like the

following:

- Raise work orders, print normal kit lists and then run this allocation analysis.

- Firm allocate items identified both physically and by re-location in the Stock Control window (pre-kitting). This avoids the need for any “bulk” kitting operation for many work orders.

- Receive in other items from POs and WOs, which will be automatically located (firm allocated) by the system, and kit physically in relevant work order boxes at the same time.

- Run Work Orders Available-to-Kit Analysis regularly to see which work orders can now be kitted, and kit (in Work Order Kit and Item Issue or Return window) as appropriate. Nothing should need to be kitted from a non-document location (everything should have been firm allocated and pre-kitted).

- Periodically run the Firm Allocation Analysis to identify items that can perhaps be shuffled about due to new priorities, or freed up.

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:48:00.00. Class wOptFirmAllocClean last modified 10 Oct 2017 11:48:27.