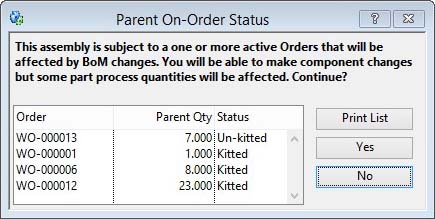

Parent On-Order Status

This window lists all current orders that are associated with a selected parent part.

You may not edit or otherwise change a BoM structure if there exists a work order for the parent part and the System Preferences have not been set to permit change in the File — System Manager — System Preferences and the Bills of Material tab pane. When a WO (or PO if the parent is an ‘O’utwork type part, or SO if the parent is a ‘P’hantom assembly) exists for a parent, all BoM associated parts have process quantities calculated on the basis of the BoM structure. If the structure is changed while the WO is in process, part quantities will be adjusted. You may either prevent this, by preventing BoM changes, or accept part process quantity changes during maintenance. You can confirm the status of process quantities using the Re-set Part Process Quantities function in the File — Advanced — Re-Set Data Files window. When you attempt to confirm your selection for a parent part, the system will check for active orders. Active orders are Work Orders for the selected part or any WO for a higher parent if the parent is a ‘P’hantom type part. They are also Sales or Purchase Orders if the parent is a ‘P’hantom type part, or SOs of higher parents if those are also ‘P’hantoms. Active orders are also Purchase Orders if the selected parent is a ‘O’utwork type part. If there are any active orders you will be warned with the display of this list of the active orders.

You can print the results of the active order analysis using the Print List button. The message will differ depending on the System Preference applicable. If you answer No you will be able to select an alternate parent part number, otherwise a Yes will give you full access to the parent BoM.

If your selected parent has any active orders the following adjustments will be made to the component part when changes (if permitted with the System Preference) are made to the BoM structure:

|

For |

Increases in BoM Qty |

Decreases in BoM Qty |

|---|---|---|

|

Backflushed WOs |

No adjustments |

No adjustments |

|

Un-kitted WOs |

Allocated increased |

Allocated decreased |

|

Kitted WOs |

Allocated increased |

WO shortages decreased |

|

Un-dispatched SOs |

Due to SO increased |

Due to SO decreased |

|

Part-dispatched SOs |

Due to SO increased |

Due to SO decreased |

|

Un-issued Outwork POs |

Allocated increased |

Allocated decreased |

|

Issued Outwork POs |

Any shortages increased |

Any shortages decreased |

|

PO Kits |

Due from P/WO increased |

Due from P/WO decreased |

The quantities applied are the order balances factored by the BoM net quantity for the part.

|

Button |

Action |

|---|---|

|

No |

Press to abort the selection of this parent considering the order status. |

|

Yes |

Press to continue with your parent selection despite the message above and considering the order status. |

|

Print List |

Will cause a report to be printed of the subject matter. Right-click to change the report destination. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 4 Jun 2012 04:47:00.00. Class wBomMessage last modified 23 Sep 2017 10:50:48.