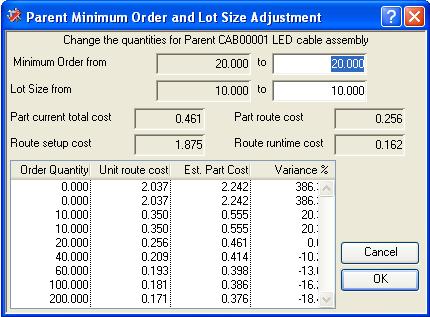

Parent Minimum Order and Lot Size Adjustment

This window is opened then you operate the Masters — Process Routes — Parent Order Quantities function having selected a parent in the Process Route Maintenance window. You can change the parent part minimum order quantity and lot size and view parent costs for different parent re-order quantities.

Because of the operation setup times the overall cost of products can be significantly affected by the normal production batch quantity. This window enables you to review the affect of minimum order quantity on the route cost and part cost. You can enter any quantities to view the cost implication. Having changed the Minimum Order Quantity and/or Lot Size, clicking OK or pressing the enter key will re-set the part quantities in the parts master record.

![]() NOTE: Part quantities will only be updated if you have “Update” privileges in the Parts maintenance menu. Otherwise two alerts will sound.

NOTE: Part quantities will only be updated if you have “Update” privileges in the Parts maintenance menu. Otherwise two alerts will sound.

|

Field |

Description |

|---|---|

|

Current Re-Order Quantity |

Parts Master. Re-order quantity. {PTMFILE.PTMREQT number 3dp} |

|

New Re-Order Quantity |

Enter a new value of Minimum Order Quantity. Tab to reveal the calculated values below. |

|

Current Lot Size |

Parts Master. Lot size when ordered. {PTMFILE.PTMLOT number 3dp} |

|

New Lot Size |

Enter a new value of Lot Size which must be less than the Minimum Order Qty. Tab to reveal the calculated values below. |

|

Part Current Total Cost |

The current cost held in the parts master for this part. |

|

Current Route Cost |

The cost of the current Route per stock unit of production based on the current Minimum Order Quantity. |

|

Setup Cost |

The total route setup cost for any batch of the part. |

|

Runtime Cost |

The route runtime cost per stock unit of production. |

|

Quantity Comparison List |

A list of different quantities around the new quantities you have entered for comparison. |

|

Button |

Action |

|---|---|

|

Cancel |

Aborts the process currently in session. The keyboard equivalent is the Esc key for Windows computers and Command-.(full stop or period) for the Mac. |

|

OK |

The OK button updates the data you have entered, or confirms the selection and/or processes the function you have called. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 24 Apr 2012 06:50:00.00. Class wProOrder last modified 23 Sep 2017 10:51:02.