BoM Reports

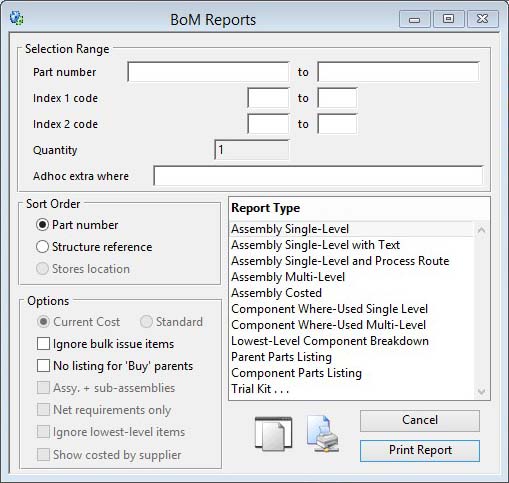

This window provides the user with the ability to set a Bill of Materials report type, sort order, options and selection ranges. The sort order, options and selection ranges available depend on the report type selected. Selecting the report type first will set the window to show only the valid alternative selection fields and option controls.

![]() NOTE: This window contains fields introduced with version 5 that enable additional search (and sometimes sort controls), such as Adhoc extra where. For more help on their use and examples see the Client-Server SQL Introduction help.

NOTE: This window contains fields introduced with version 5 that enable additional search (and sometimes sort controls), such as Adhoc extra where. For more help on their use and examples see the Client-Server SQL Introduction help.

Once the user has completed the window pressing the Enter key will cause the report to be printed, clicking on the Print Report button has the same effect. A Cancel button closes the window.

The Trial Kit is a special type, in that it requires additional setup using the BoM Trial Kit Parts Setup window.

![]() TIP: The Parent Parts Listing report exhibits special behaviour when driven by the Transfer List function on the Parts ScratchPad. You can use this to obtain a list of all parent parts that contain a multiple selection of component parts. For example, all assemblies that contain IC1, IC4 and TR6; to do this, with the BoM Reports window open and Parent Parts Listing report selected, open the Parts ScratchPad and populate it so that the three components are included. Select the component part lines, using Ctrl-click, then operate Transfer List from the Parts ScratchPad Options menu. If the system can find any parent parts that contain all of the selected components, the ScratchPad list will be replaced by the list of these parents. If it cannot find any parents, you will be notified in a message. Note that if you only select one component part the resulting list will be a single-level where-used list.

TIP: The Parent Parts Listing report exhibits special behaviour when driven by the Transfer List function on the Parts ScratchPad. You can use this to obtain a list of all parent parts that contain a multiple selection of component parts. For example, all assemblies that contain IC1, IC4 and TR6; to do this, with the BoM Reports window open and Parent Parts Listing report selected, open the Parts ScratchPad and populate it so that the three components are included. Select the component part lines, using Ctrl-click, then operate Transfer List from the Parts ScratchPad Options menu. If the system can find any parent parts that contain all of the selected components, the ScratchPad list will be replaced by the list of these parents. If it cannot find any parents, you will be notified in a message. Note that if you only select one component part the resulting list will be a single-level where-used list.

|

Field |

Description |

|---|---|

|

Report List |

Select a report type. Any custom reports entered in the Settings will appear at the bottom of the list. |

|

Selection Range |

Enter data that restricts the records selected. If left blank, data will be selected from the maximum and minimum extremes in the file. All selections criteria you enter will have to be met by each record processed. |

|

Quantity |

Enter the quantity of the assembly for analysis. This is only useful where you are wanting to compare current physical stock with the material requirements. |

|

Sort by Part number |

Sorts the component listings in part number order. |

|

Sort by Structure reference |

Sorts the component listings in BoM structure reference order. |

|

Sort by Stores location |

Sorts the component listings in stores location order of the component part. |

|

Current Cost |

The costed report will be based on part Current Costs. |

|

Standard |

The costed report will be based on part Standard Costs. |

|

Ignore bulk issue items |

Check this option to ignore all components that are flagged for Bulk Issue in the Parts file. |

|

No listing for ‘Buy’ parents |

Checking this option will prevent the report from listing assemblies where the parent has a ‘B’uy part type. |

|

Assy. + sub-assemblies |

This option limits the report to the selected assembly and all sub-assemblies (at all levels) contained within it. |

|

Net requirements only |

Check this option if you want the report to show only those items where physical quantity is insufficient for the net requirements of the parent. |

|

Ignore lowest-level items |

Check this option to avoid printing lowest level items within the multi-level assembly. This enables the report to show the sub-assembly structure alone, without components and materials. |

|

Show costed by supplier |

Check this option to obtain a costed report. It will be sorted and subtotalled by Part Primary Supplier. |

|

Button |

Action |

|---|---|

|

Cancel |

Aborts the process currently in session. The keyboard equivalent is the Esc key for Windows computers and Command-.(full stop or period) for the Mac. |

|

Print Report |

Will cause a report to be printed of the subject matter. Right-click to change the report destination. |

| See also: – |

Compiled in Program Version 5.10. Help data last modified 3 Jan 2015 10:18:00.00. Class wBomPrint last modified 17 Oct 2017 04:29:54.